Preparation method of target-grade ultrahigh-purity tantalum metal

An ultra-high and target technology, which is applied in the field of target-grade ultra-high-purity tantalum metal production, can solve problems such as deterioration of interface characteristics, complex mineral composition, and influence on component actions, so as to reduce production costs and save refining times Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention provides a preparation method of target-grade ultra-high-purity tantalum metal. The basic steps of the method are as follows:

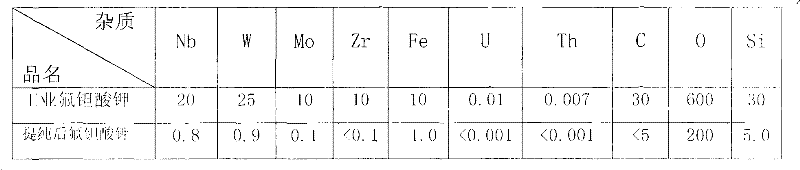

[0024] 1) For industrial grade potassium fluorotantalate K 2 TaF 7 Recrystallization and purification by wet smelting. The process route is to dissolve industrial grade K with hydrofluoric acid HF solution. 2 TaF 7 , add potassium ion solution in excess according to the theoretical amount, so that K 2 TaF 7 Recrystallization, the K 2 TaF 7 The recrystallized body is washed with alkali and dried to obtain slightly acidic K 2 TaF 7 Crystals;

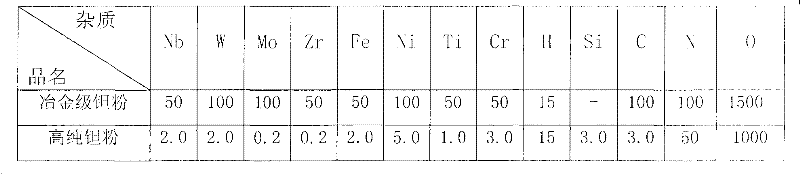

[0025] 2) For the slightly acidic K obtained 2 TaF 7 The crystal is reduced by fire smelting, and the process route is to convert K 2 TaF 7 The crystal is reduced to tantalum powder with sodium Na, and then washed with water, pickled and heat treated to obtain ultra-high-purity tantalum powder.

[0026] Wherein, the pair of industrial grade potassium fluorotantalate K 2 TaF 7The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com