Film bulk acoustic wave resonator prepared by employing ultrathin piezoelectric single crystal

A piezoelectric single crystal and thin-film bulk acoustic wave technology, applied in electrical components, impedance networks, etc., can solve problems such as low technical difficulty of single crystal ultra-thin slices, influence of single crystal characteristics, large damage to crystal structure integrity, etc., and achieve production The effect of bright technology prospects and optimized device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

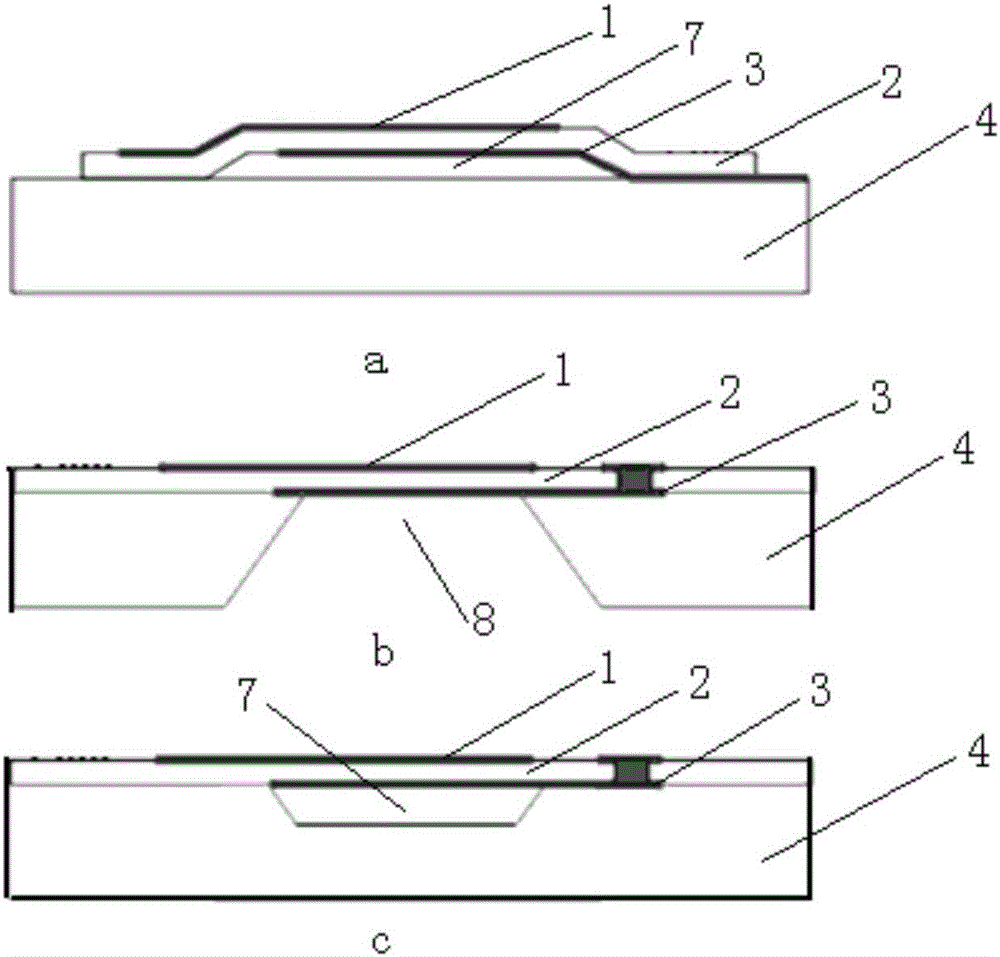

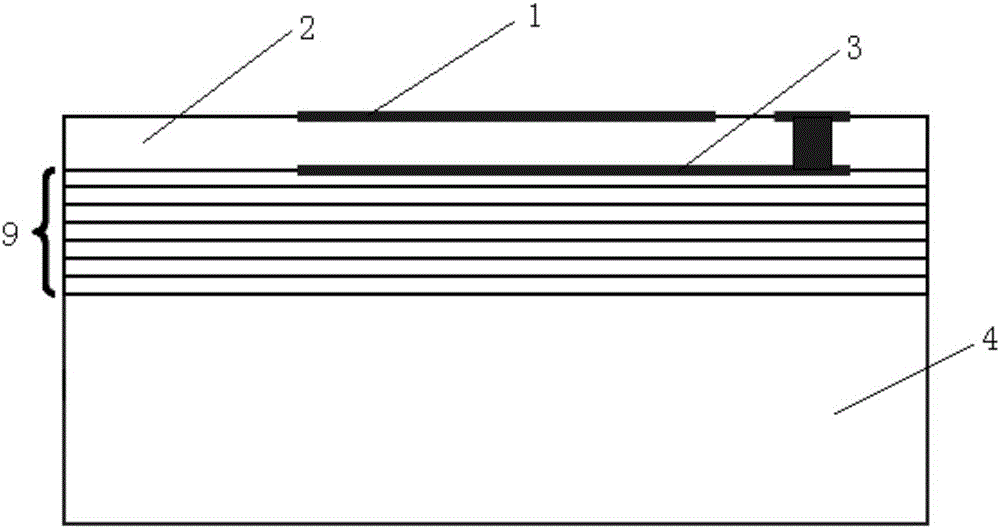

[0053] The manufacturing procedure of embodiment one is as Figure 8 to Figure 16 It belongs to conventional microelectronics process technology. The invention adopts two single-sided polished wafers of the same size: a high-resistance silicon substrate and a piezoelectric single crystal, and the polished surface is called the front side.

[0054] Figure 8 It is the CFBAR embodiment 1 process flow 1: cleaning the high-resistance silicon substrate, and etching the basement pattern on the front side. The present invention adopts a basement structure with pillars, and this technical scheme has been described in detail in our earlier application for invention patents.

[0055] Figure 9 It is CFBAR embodiment 1 process flow 2: adopt standard process to etch silicon on the high-resistance silicon substrate to form a basement with pillars.

[0056] Figure 10 It is CFBAR embodiment 1 process flow 3: a bonding layer is deposited on the patterned front side of the high-resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com