RE3Ta/NbO7 (Rare-Earth Tantalite/Niobate) ceramic powder and preparation method thereof

A technology of ceramic powder and niobate, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., to achieve the effect of short drying time, reducing adverse effects and reducing impurity elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

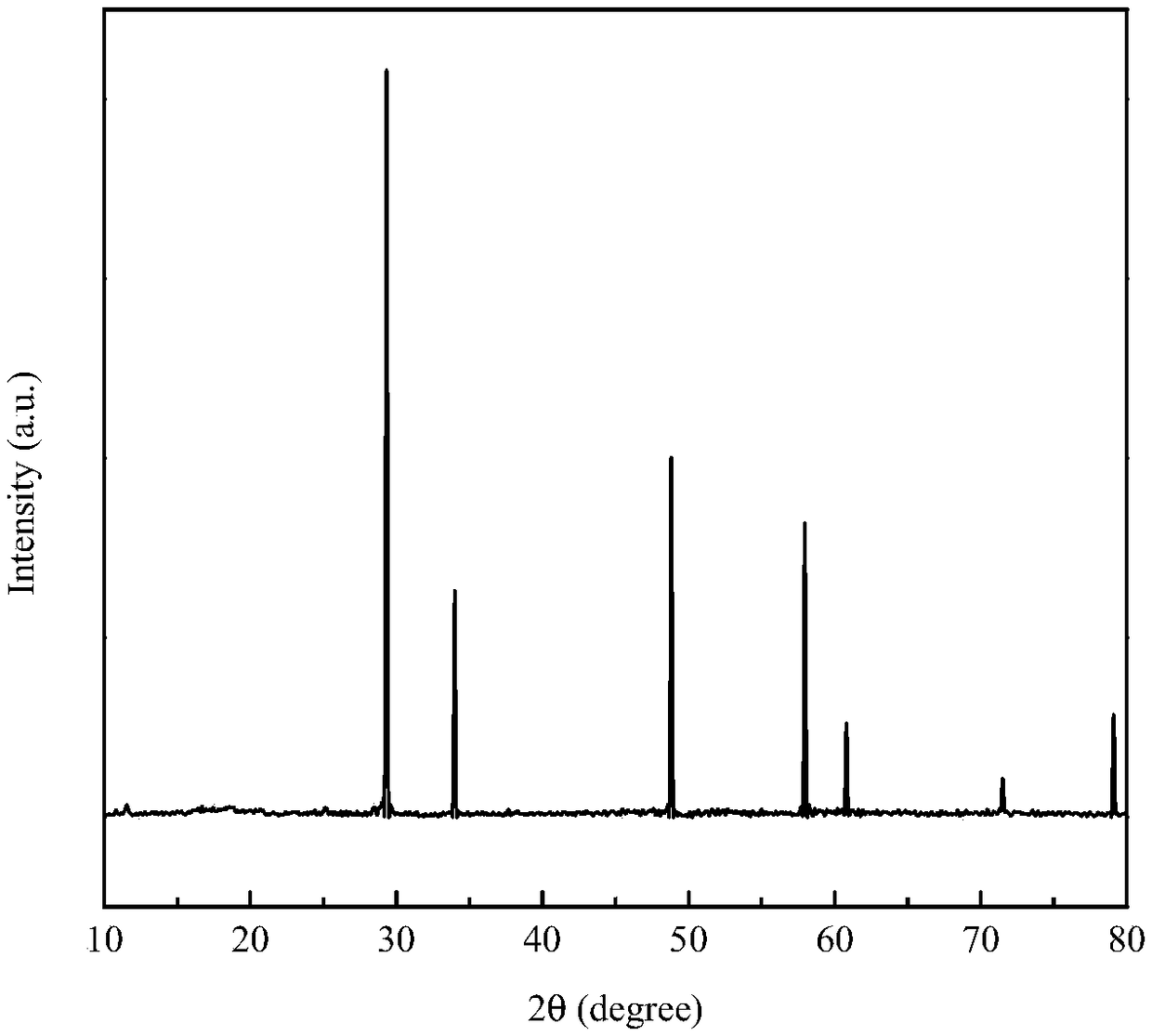

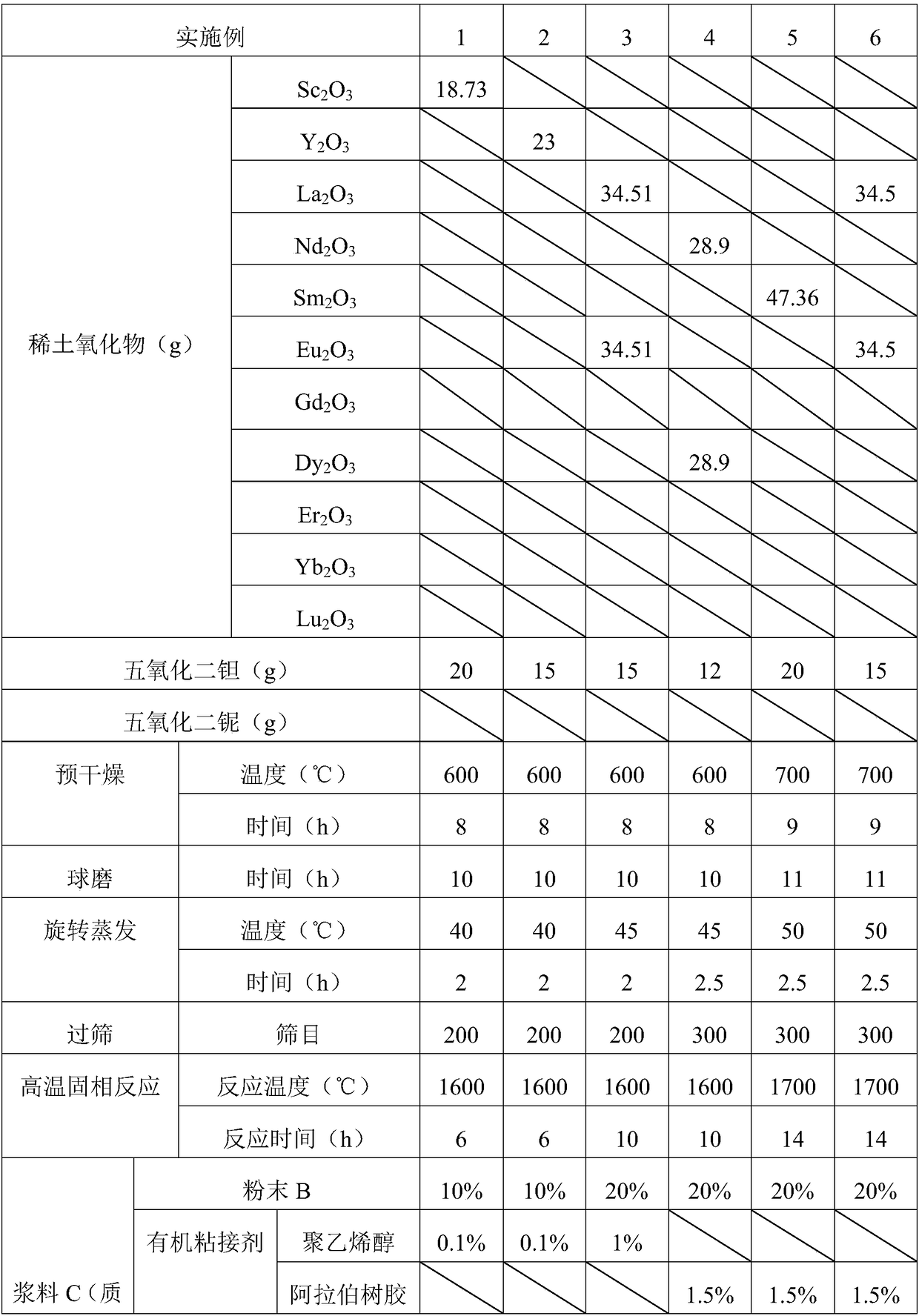

[0036] Rare earth tantalum niobate (RE 3 Ta / NbO 7) The preparation method of ceramic powder, comprises the following steps:

[0037] Step (1): the rare earth oxide powder (rare earth oxide is Sc 2 o 3 , Y 2 o 3 , La 2 o 3 、Nd 2 o 3 、Sm 2 o 3 、Eu 2 o 3 、Gd 2 o 3 、Dy 2 o 3 、Er 2 o 3 , Yb 2 o 3 、Lu 2 o 3 One or more of them), tantalum pentoxide (Ta 2 o 5 ) powder or niobium pentoxide (Nb 2 o 5 ) powder for pre-drying, the pre-drying temperature is 600-800°C, the pre-drying time is 8-10h, according to RE 3 Ta / NbO 7 The stoichiometric ratio of the corresponding elements weighs the pre-dried powder, and then adds it to deionized water or ethanol solvent to obtain a mixed solution, so that the molar ratio of RE:Ta / Nb in the mixed solution is 3:1, and the mixed solution is mixed with a ball mill. Carry out ball milling, the time of ball milling is not less than 10h, the rotating speed of ball mill is not less than 300 rpm.

[0038] The slurry obtained afte...

Embodiment 2

[0054] The rare earth tantalate (Y) prepared by embodiment 2 2 TaO 7 ) SEM spectrum of ceramic powder such as figure 2 shown, from figure 2 It can be seen that the particle size of the powder is 10-50 μm, and the shape is spherical.

[0055] Enumerate comparative example 3 groups and the ceramic powder that embodiment 1-12 obtains compares:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com