Iron oxide/carbon composite lithium ion battery anode material as well as preparation method and application thereof

A carbon composite material, iron oxide technology, applied in battery electrodes, carbon preparation/purification, iron oxide/iron hydroxide, etc., to achieve the effects of improving electronic conductivity, high specific capacity, and simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

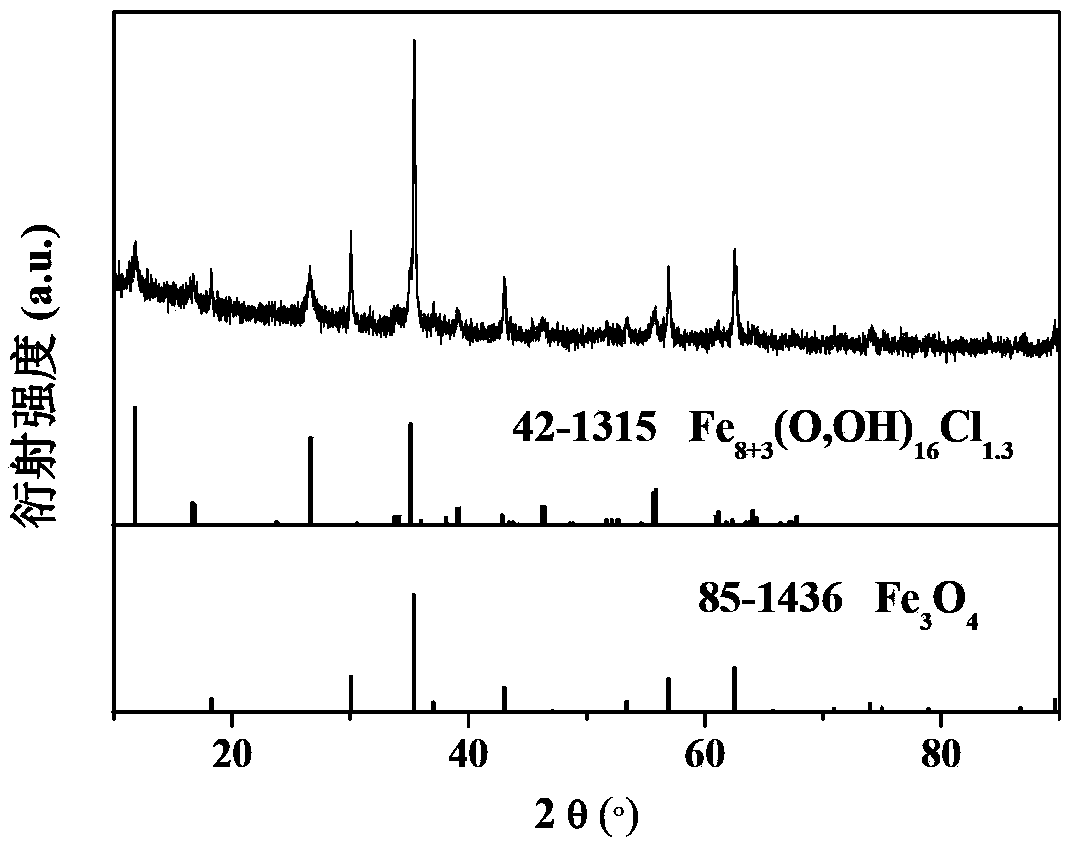

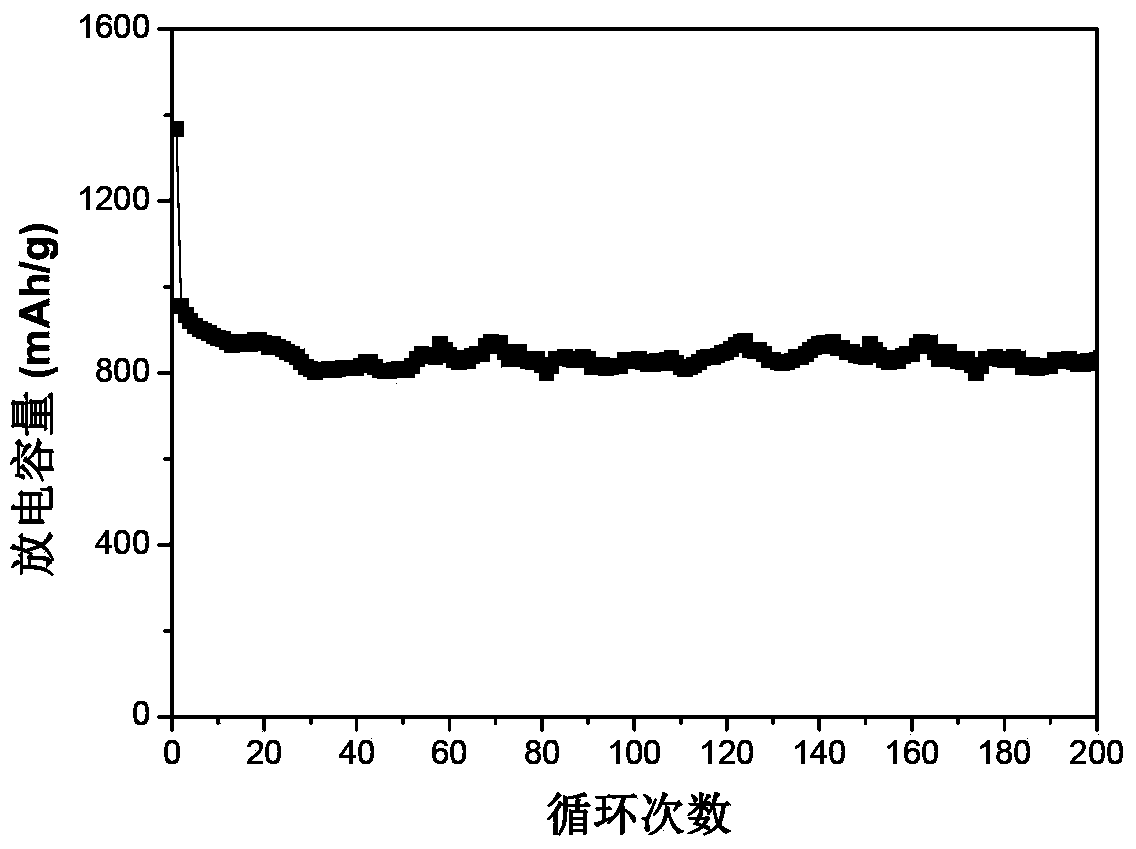

[0054] Using FeCl 3 As the iron source, prepare a solution with a molar concentration of 2.2 mol / liter. The solution was heated to 100 °C, and the FeCl 3 Ammonia (15 mol / L) was added to FeCl at a molar ratio of 10:1 3 aqueous solution, and added with FeCl 3 Citric acid with a molar ratio of 3:1 will form a liquid mixture after being fully stirred. The above solution was sprayed and cracked in air at 400°C to obtain a powder precursor. Then, the powder precursor was calcined at 450° C. for 3 hours under a nitrogen atmosphere to obtain an iron oxide / carbon composite material. According to X-ray diffraction detection, the crystalline oxide in the composite material is mainly Fe 3 o 4 . According to the elemental analysis method, the carbon content in the composite material is 20% of the weight percentage of the composite material. According to diffraction analysis by transmission electron microscope, the composite material also contains amorphous iron oxide.

[0055] Pre...

Embodiment 2

[0064] Using FeCl 3 As an iron source, prepare a solution with a molar concentration of 4.0 mol / liter. At room temperature, the solution was added with FeCl 3 The molar ratio is 8:1 ammonia water (concentration is 8 mol / L), and then added with FeCl 3 The molar ratio of citric acid is 3:1, stir well to form a liquid phase mixture. The above liquid phase mixture is subjected to spray cracking in an air atmosphere at 400°C to form a powder material. Then the powder material in N 2 Under the atmosphere, the iron oxide / carbon composite material was obtained by calcining at 500° C. for 3 hours. According to X-ray diffraction detection, the crystalline oxide in the composite material is mainly Fe 3 o 4. Through transmission electron microscope energy spectrum analysis and selected area diffraction analysis of iron and oxygen-containing regions, the material contains amorphous oxides. According to elemental analysis, the carbon content in the composite material is 15% by weigh...

Embodiment 3

[0068] Using FeCl 3 As the iron source, prepare a solution with a molar concentration of 2.2 mol / liter. The solution was heated to 50°C, and FeCl was added to the solution 3 Aqueous ammonia (1.5 mol / L) at a molar ratio of 12:1 was stirred, and then added with FeCl 3 The molar ratio of citric acid is 4:1, stir well to form a liquid phase mixture. The above-mentioned liquid phase mixture is subjected to spray cracking in an air atmosphere at 300° C. to form a powder material. Then the powder material in N 2 Under the atmosphere, the iron oxide / carbon composite material was obtained by calcining at 450° C. for 3 hours. According to X-ray diffraction detection, the crystalline oxide in the composite material is mainly Fe 3 o 4 . According to elemental analysis, the carbon content in the composite material is 25% by weight of the composite material.

[0069] A simulated battery was assembled using the same method as in Example 1, and the electrochemical performance of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com