Rare earth permanent magnetism material and its making method

A technology of rare earth permanent magnets and manufacturing methods, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., and can solve problems affecting the magnetic properties of magnets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

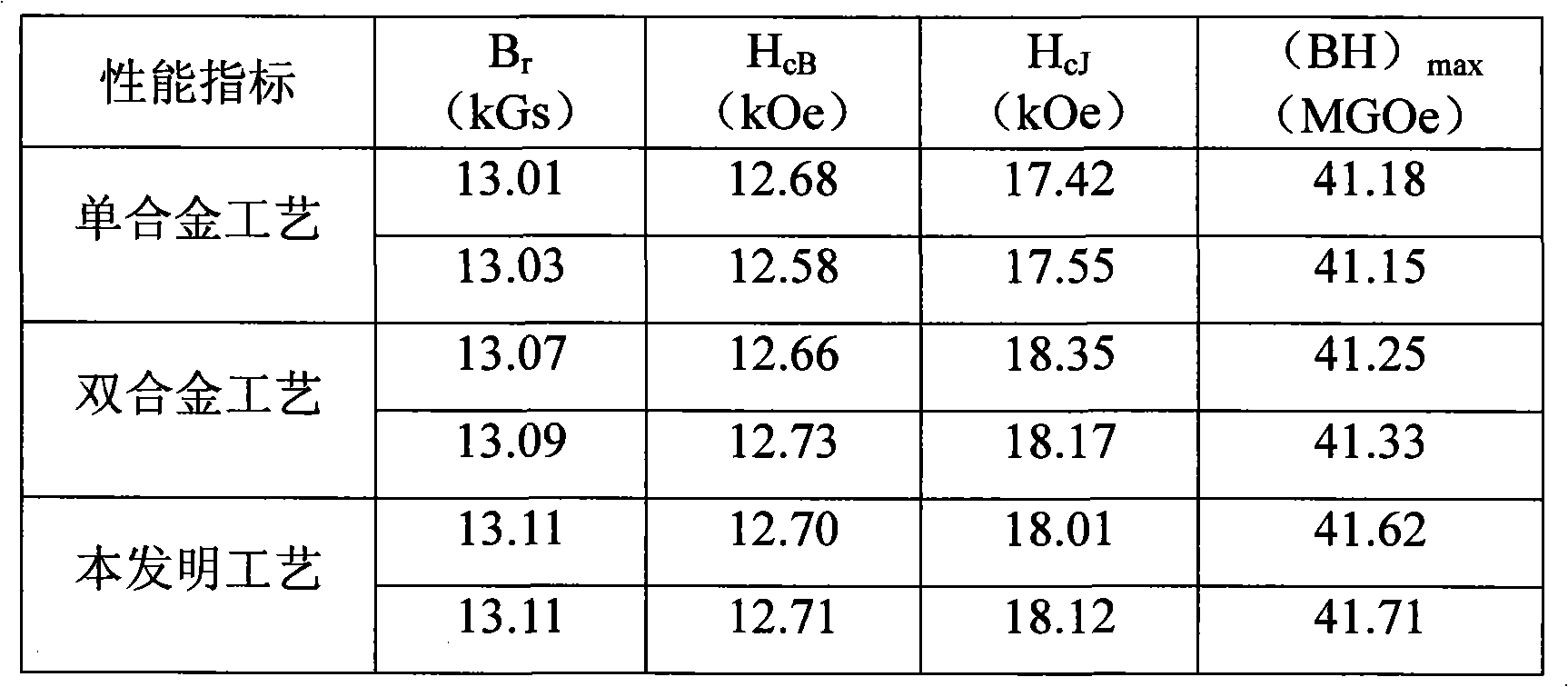

Embodiment 1

[0035]Neodymium (Nd), Dy-Fe, Terbium (Tb), Fe-B, Nb-Fe, Co, Al, Cu and Fe are used to provide an alloy composition consisting of 28.5% by weight Nd, 1% (weight) of Dy, 0.5 (weight) of Tb, 1.00% (weight) of B, 0.4% (weight) of Nb, 1.00% (weight) of Co, 0.20% (weight) of Al, 0.10% ( weight) of Cu and the balance of Fe. The raw material was melted in an alumina crucible in a high-frequency vacuum induction furnace under an argon atmosphere. Alloy flakes about 0.3-0.5 mm thick are formed by quick-setting method. The high-temperature alloy flakes separated from the casting rolls were kept warm for 1 hour in a box made of high heat insulating material. The alloy sheet is then loaded into a box with a water-cooled structure to rapidly cool the strip to room temperature. Hydrogen is absorbed in the obtained alloy at room temperature, and then released from the alloy at 560°C, and the alloy is broken into alloy powders of about 0.5mm by using the deformation in the hydrogen absorpti...

Embodiment 2

[0038] Neodymium (Nd), Dy-Fe, Terbium (Tb), Fe-B, Nb-Fe, Co, Al, Cu and Fe are used to provide an alloy composition consisting of 27.5% by weight Nd, 1.5% (weight) of Dy, 1 (weight) of Tb, 1.00% (weight) of B, 0.4% (weight) of Nb, 1.00% (weight) of Co, 0.20% (weight) of Al, 0.10% ( weight) of Cu and the balance of Fe. The raw material was melted in an alumina crucible in a high-frequency vacuum induction furnace under an argon atmosphere. Alloy flakes about 0.3-0.5 mm thick are formed by quick-setting method. The high-temperature alloy flakes separated from the casting rolls were kept warm for 1 hour in a box made of high heat insulating material. The alloy sheet is then loaded into a box with a water-cooled structure to rapidly cool the strip to room temperature. Hydrogen is absorbed in the obtained alloy at room temperature, and then released from the alloy at 560°C, and the alloy is broken into alloy powders of about 0.5mm by using the deformation in the hydrogen absorpt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com