Method for producing potassium-calcium fertilizer by using potassium feldspar, limestone and phosphogypsum

A technology for phosphogypsum and limestone, which is applied in the fields of environmental protection and chemical production, can solve the problems of complex process, high energy consumption, large amount of waste residue, etc., and achieve the effect of short sintering time and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Raw material 1: Potassium feldspar, collection location: Feng County, Jiangsu

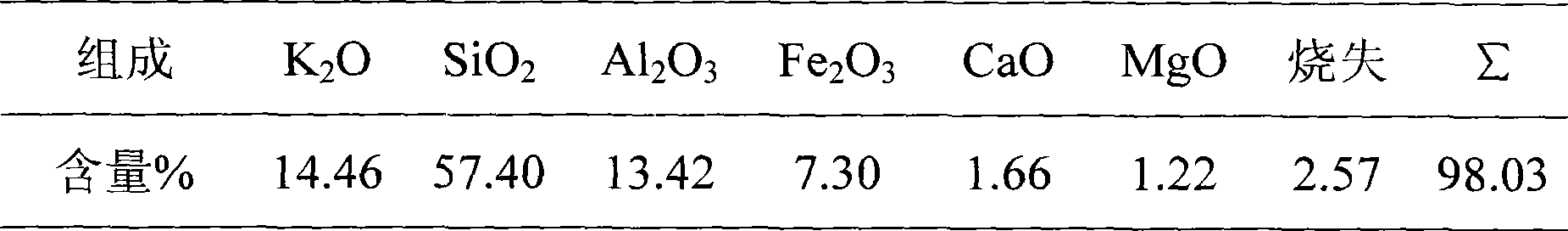

[0020] The chemical composition of potassium feldspar is shown in the table below

[0021]

[0022] Raw material 2: Phosphogypsum, collection location: Guizhou Xiyang Fertilizer Co., Ltd.

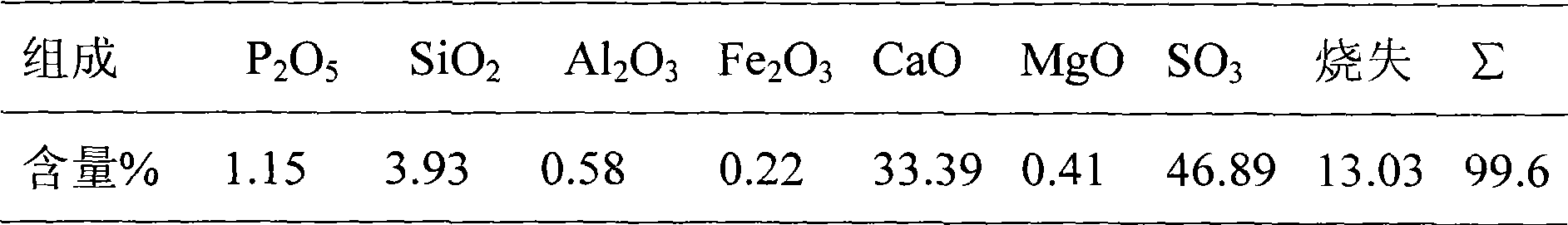

[0023] The chemical composition of phosphogypsum is shown in the table below

[0024]

[0025] Raw material 3: limestone, collection location: Xifeng, Guizhou

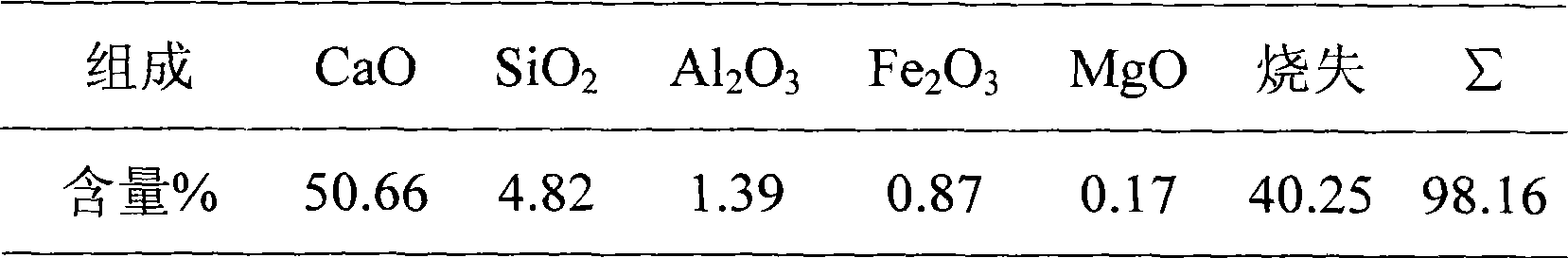

[0026] The chemical composition of limestone is shown in the table below

[0027]

Embodiment approach

[0029] The pre-crushed potassium feldspar, limestone and phosphogypsum are mixed with an electronic scale at a mass ratio of 1:0.9:0.6, and the mixed material is dried by a dryer and then ground to 120 mesh with a ball mill (residual sieve ≤ 5%) , the powder is formed into balls by adding water in the disc-type ball forming machine. The particle size of the balls is controlled at φ10-φ30mm, and the water content is 10%-15%. The time is 40 minutes, the sintered clinker is cooled and ground to 80 meshes with a ball mill, and the sieve residue <5% is packaged to be the finished product of potassium calcium fertilizer.

[0030] Implementation results:

[0031] The active ingredients of the potassium-calcium fertilizer prepared by testing are shown in the table below

[0032]

[0033] It can be seen from the above table that the indicators of active components of the potassium calcium fertilizer prepared through industrial tests meet the enterprise standards. K in potassium or...

Embodiment 2

[0035] Raw material 1: Potassium feldspar, collection location: Feng County, Jiangsu

[0036] The chemical composition of potassium feldspar is shown in the table below

[0037]

[0038] Raw material 2: Phosphogypsum, collection location: Guizhou Xiyang Fertilizer Co., Ltd.

[0039] The chemical composition of phosphogypsum is shown in the table below

[0040]

[0041] Raw material 3: limestone, collection location: Xifeng, Guizhou

[0042] The chemical composition of limestone is shown in the table below

[0043]

[0044] method of execution:

[0045] The pre-crushed potassium feldspar, limestone and phosphogypsum are mixed with an electronic scale at a mass ratio of 1:0.9:0.7, and the mixed material is dried by a dryer and then ground to 120 mesh with a ball mill (residual sieve ≤ 5%) , the powder is formed into balls by adding water in the disc-type ball forming machine. The particle size of the balls is controlled at φ10-φ30mm, and the water content is 10%-15%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com