Biomedical beta-titanium alloy material and preparation method

A biomedical, titanium alloy technology, applied in medical science, prosthesis, etc., can solve the problems of simplification of use, containing toxic elements, etc., and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

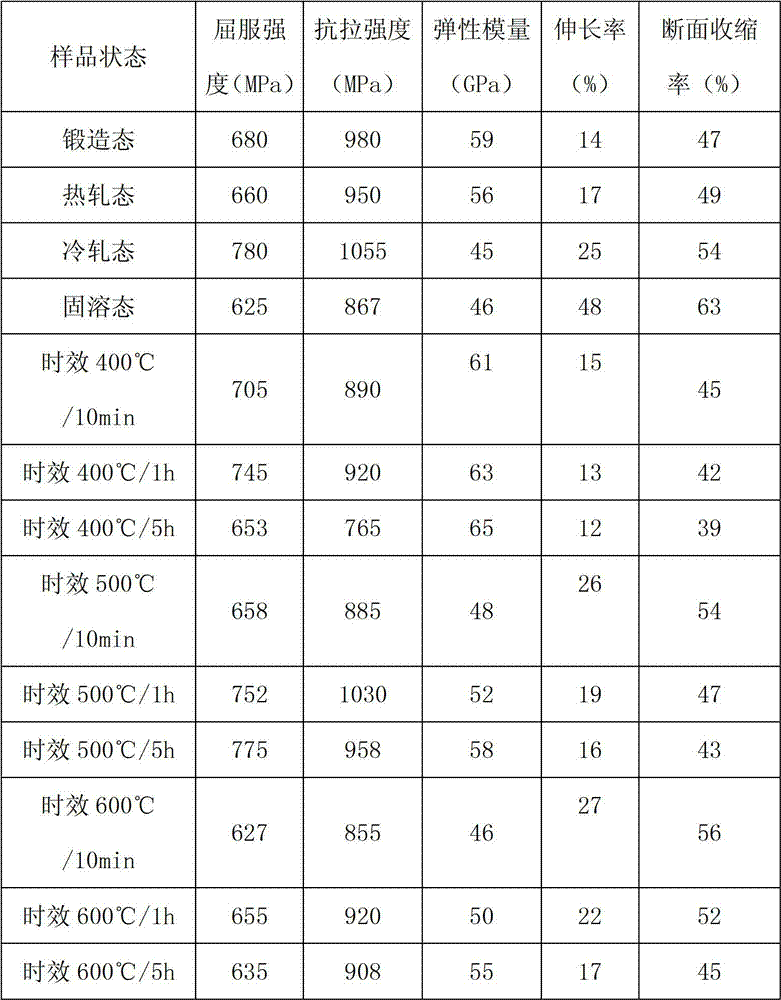

Embodiment 1

[0035] 1. Ingredients: Ti-36Nb-10Zr-2Sn-0.2O alloy, in which Ti is sponge titanium, Zr is sponge zirconium, high melting point element Nb and volatile element Sn are all in the form of Ti-52Nb and Ti-80Sn master alloys respectively To add, the content of O is controlled by the content of oxygen in the sponge Ti. Ingredients are formulated according to the mass percentage of the alloy composition.

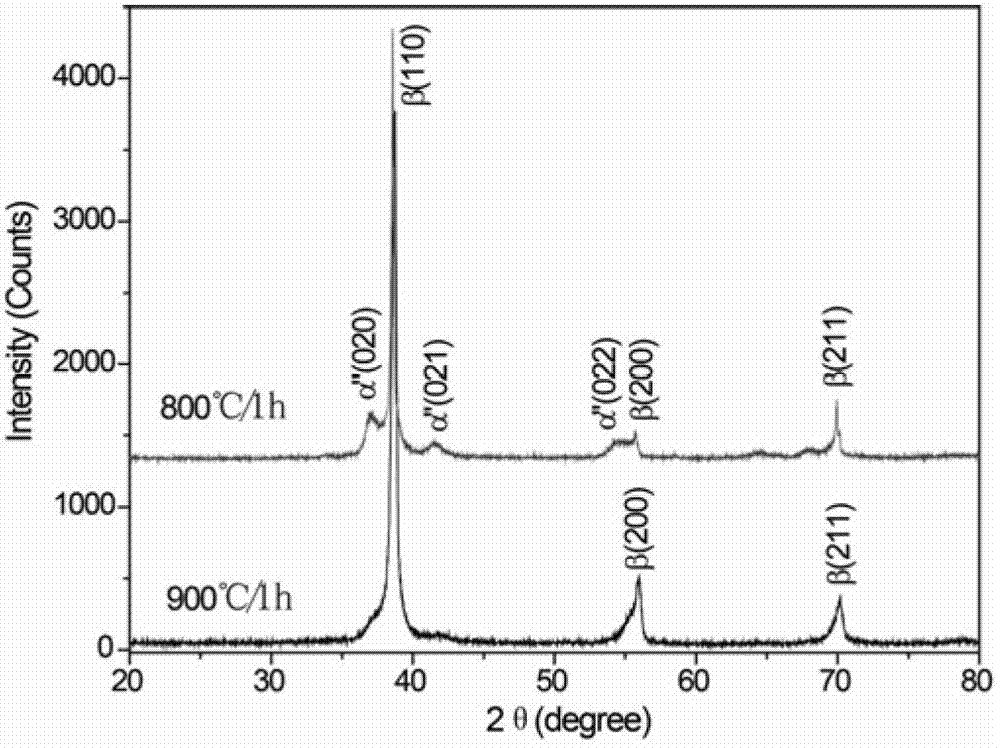

[0036] 2. Smelting: The prepared raw materials are pressed into electrodes on a hydraulic press, and smelted twice in a vacuum consumable electric arc furnace. The vacuum degree is not lower than 10 before each smelting. -2 Pa, made alloy ingot. After sufficient cooling, samples were taken for differential thermal analysis and metallographic analysis, and the β→α phase transition temperature of the alloy was measured, and chemical methods were used to analyze whether there was composition segregation in the ingot. Then perform homogenization annealing (with Ar gas protection) in a...

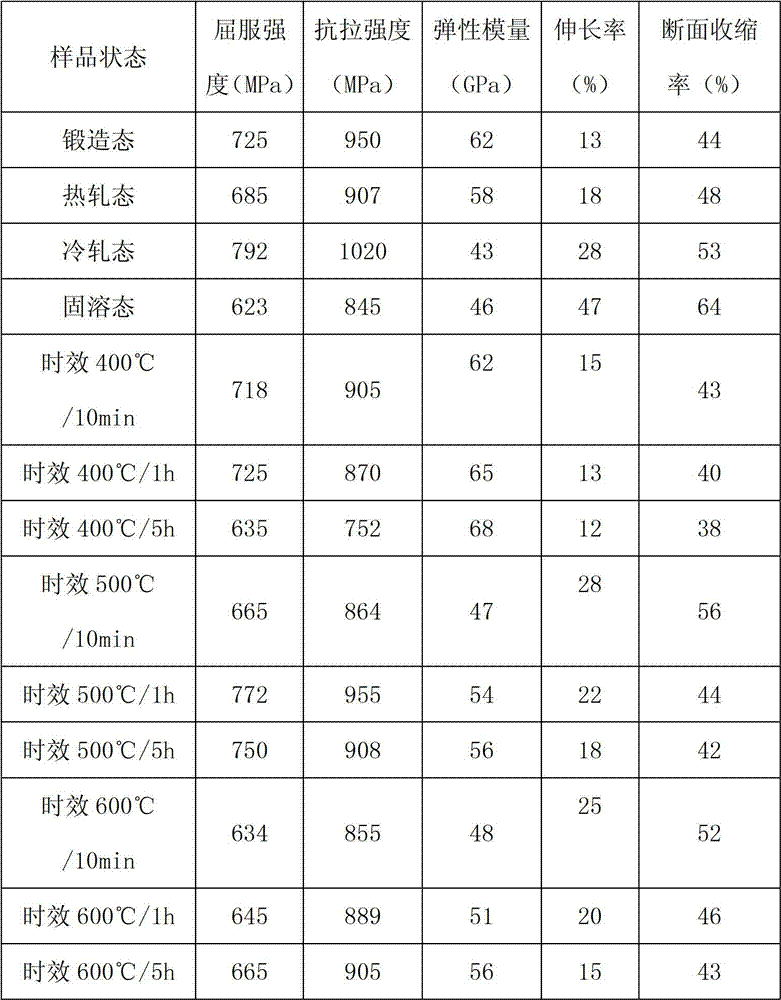

Embodiment 2

[0046] 1. Ingredients: Ti-36Nb-10Zr-5Sn-0.3O alloy, in which Ti is sponge titanium, Zr is sponge zirconium, high melting point element Nb and volatile element Sn are all in the form of Ti-52Nb and Ti-80Sn master alloys respectively To add, the content of O is controlled by the content of oxygen in the sponge Ti. Ingredients are formulated according to the mass percentage of the alloy composition.

[0047] 2. Smelting: The prepared raw materials are pressed into electrodes on a hydraulic press, and smelted twice in a vacuum consumable electric arc furnace. The vacuum degree is not lower than 10 before each smelting. -2 Pa, made alloy ingot. After sufficient cooling, samples were taken for differential thermal analysis and metallographic analysis, and the β→α phase transition temperature of the alloy was measured, and chemical methods were used to analyze whether there was composition segregation in the ingot. Then perform homogenization annealing (with Ar gas protection) in a...

Embodiment 3

[0057] 1. Ingredients: Ti-35Nb-10Zr-8Sn-0.2O alloy, in which Ti is sponge titanium, Zr is sponge zirconium, high melting point element Nb and volatile element Sn are all in the form of Ti-52Nb and Ti-80Sn master alloys respectively To add, the content of O is controlled by the content of oxygen in the sponge Ti. Ingredients are formulated according to the mass percentage of the alloy composition.

[0058] 2. Smelting: The prepared raw materials are pressed into electrodes on a hydraulic press, and smelted twice in a vacuum consumable electric arc furnace. The vacuum degree is not lower than 10 before each smelting. -2 Pa, made alloy ingot. After sufficient cooling, samples were taken for differential thermal analysis and metallographic analysis, and the β→α phase transition temperature of the alloy was measured, and chemical methods were used to analyze whether there was composition segregation in the ingot. Then perform homogenization annealing (with Ar gas protection) in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com