Preparation method of calcium phosphate composite bone cement

A technology of bone cement and calcium phosphate, which is applied in the field of preparation of calcium phosphate composite bone cement, can solve the problems of large and only 26-28% reduction, and achieve the effects of low cost, simple process and improved compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

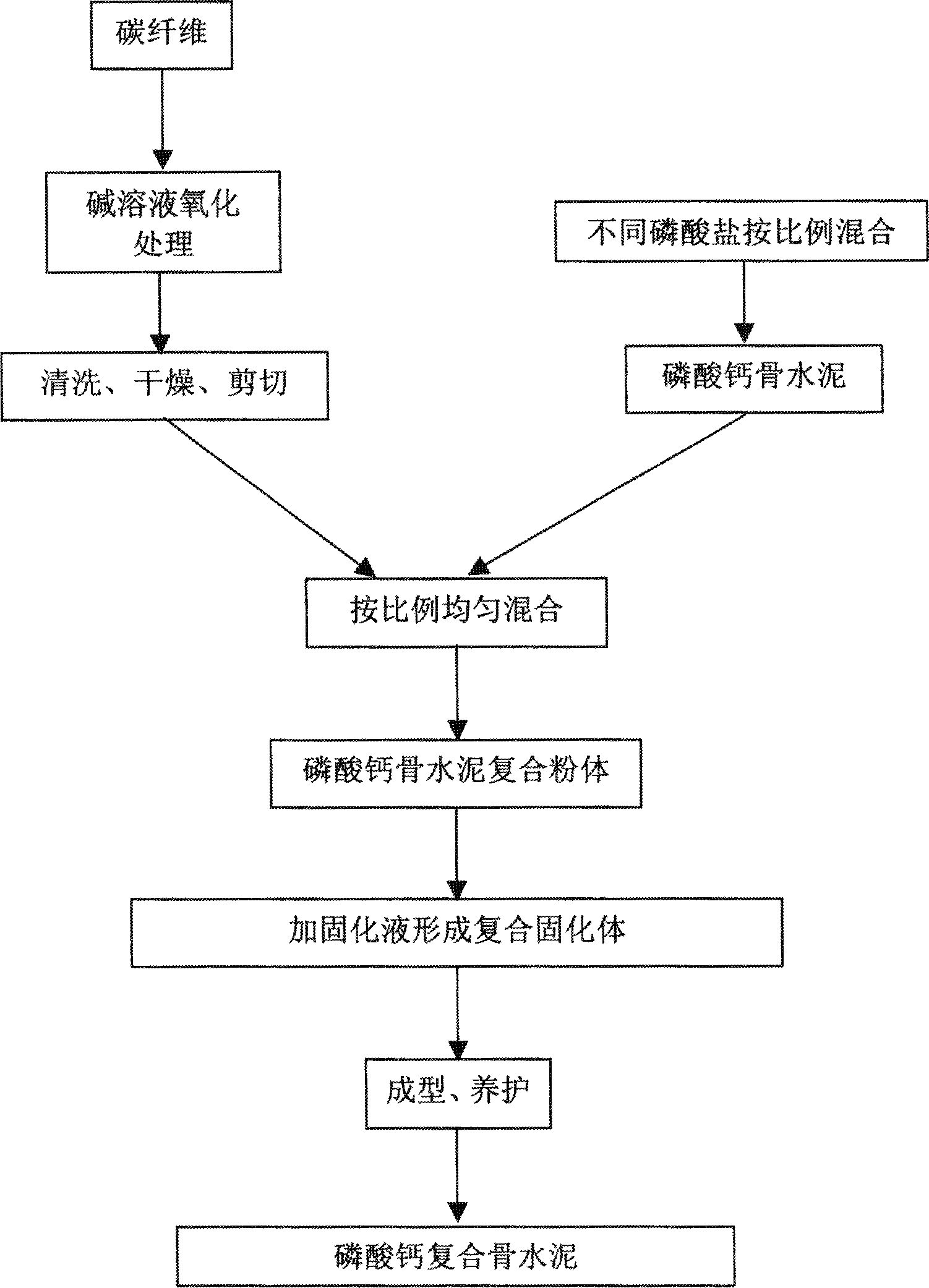

[0021] A preparation method of calcium phosphate composite bone cement, such as figure 1 shown, including the following steps:

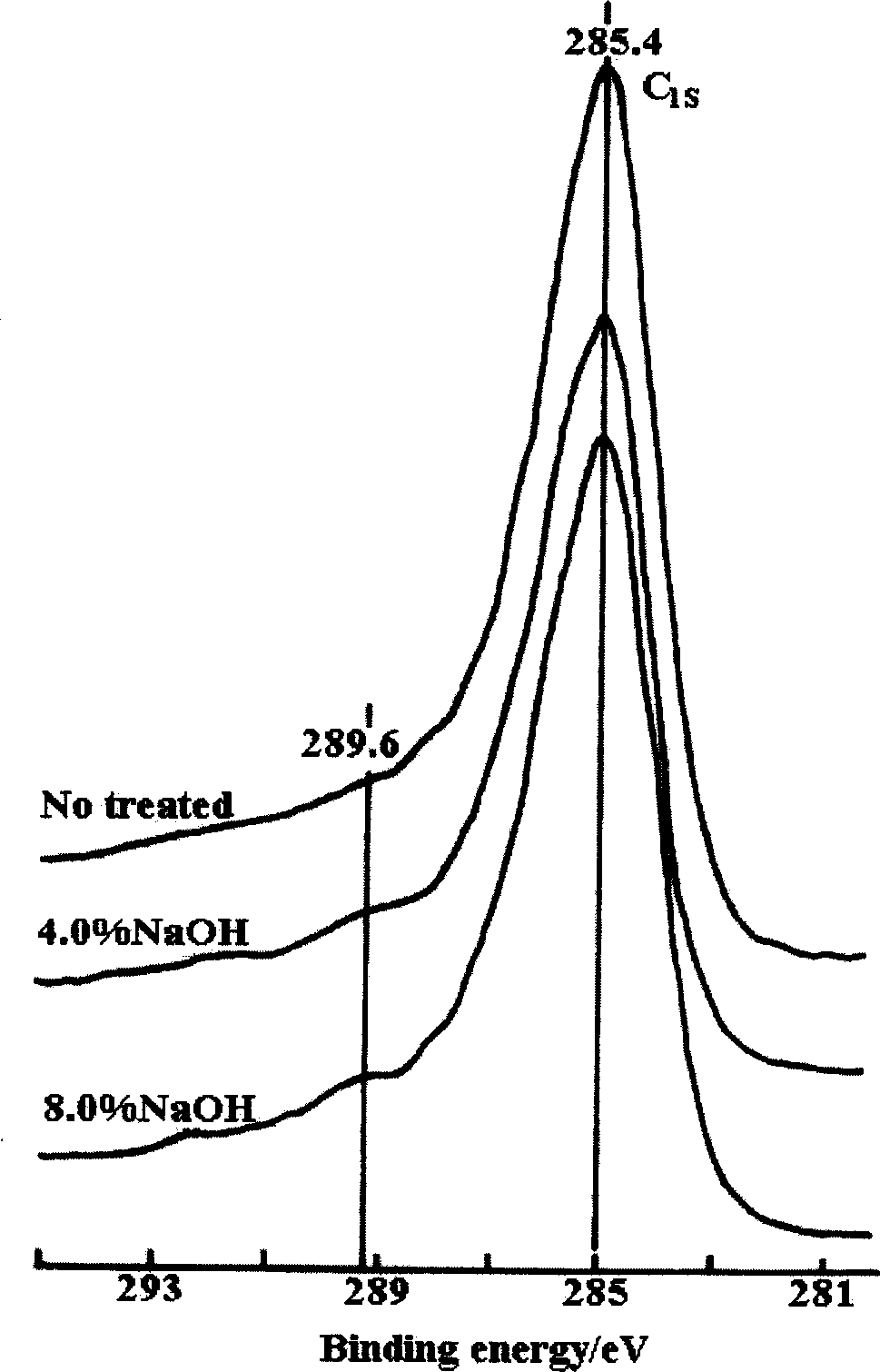

[0022] 1). Surface treatment of carbon fiber: first, oxidize the carbon fiber with sodium hydroxide solution to increase the oxygen content on the surface of the carbon fiber; use a diameter of 12 μm, a tensile strength of 80-120kgf / mm, and a Young's modulus of 5-10 ×10 3 kg / mm 2 Clean the carbon fiber with distilled water, dry it, then immerse the dried carbon fiber in a NaOH solution with a concentration of 2-10%, and heat it at 80°C for 2 hours; rinse the treated carbon fiber with distilled water, and heat it at 150°C After drying, the carbon fiber is cut into 1mm-8mm for later use (according to aspect ratio 125-625). Such as figure 2 As shown, after being treated with NaOH solution, the main peak broadened, and the small peak appeared and moved to the direction of high binding energy. The greater the concentration of NaOH, the more obvious t...

Embodiment 2

[0040] A preparation method of calcium phosphate composite bone cement, such as figure 1 shown, including the following steps:

[0041] 1). Surface treatment of carbon fiber: first, oxidize the carbon fiber with sodium hydroxide solution to increase the oxygen content on the surface of the carbon fiber; use a diameter of 12 μm, a tensile strength of 80-120kgf / mm, and a Young's modulus of 5-10 ×10 3 kg / mm 2 Clean the carbon fiber with distilled water, dry it, then immerse the dried carbon fiber in a NaOH solution with a concentration of 2-10%, and heat it at 80°C for 2 hours; rinse the treated carbon fiber with distilled water, and heat it at 150°C Dry, cut the carbon fiber into 1mm-8mm for later use, carbon fiber diameter ratio=125-625;

[0042] 2). Preparation of composite powder: fully mix tetracalcium phosphate and anhydrous calcium hydrogen phosphate at a Ca / P molar ratio of 1.67 to obtain calcium phosphate bone cement;

[0043]0.05-2% of the carbon fiber obtained in t...

Embodiment 3

[0052] A preparation method of calcium phosphate composite bone cement, such as figure 1 shown, including the following steps:

[0053] 1). Surface treatment of carbon fiber: first, oxidize the carbon fiber with sodium hydroxide solution to increase the oxygen content on the surface of the carbon fiber; use a diameter of 12 μm, a tensile strength of 80-120kgf / mm, and a Young's modulus of 5-10 ×10 3 kg / mm 2 Clean the carbon fiber with distilled water, dry it, then immerse the dried carbon fiber in a NaOH solution with a concentration of 2-10%, and heat it at 80°C for 2 hours; rinse the treated carbon fiber with distilled water, and heat it at 150°C Dry, cut the carbon fiber into 1mm-12mm for later use, carbon fiber aspect ratio=80-1000;

[0054] 2). Preparation of composite powder: fully mix α-tricalcium phosphate, calcium dihydrogen phosphate and calcium carbonate at a Ca / P molar ratio of 1.60 to obtain calcium phosphate bone cement;

[0055] 0.05-2% of the carbon fiber ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com