Method for preparing gradient porous ceramic by using centrifugal freeze drying technology

A gradient porous and ceramic technology, applied in ceramic products, applications, household appliances, etc., can solve problems such as material failure, achieve good mechanical properties and stability, and small residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

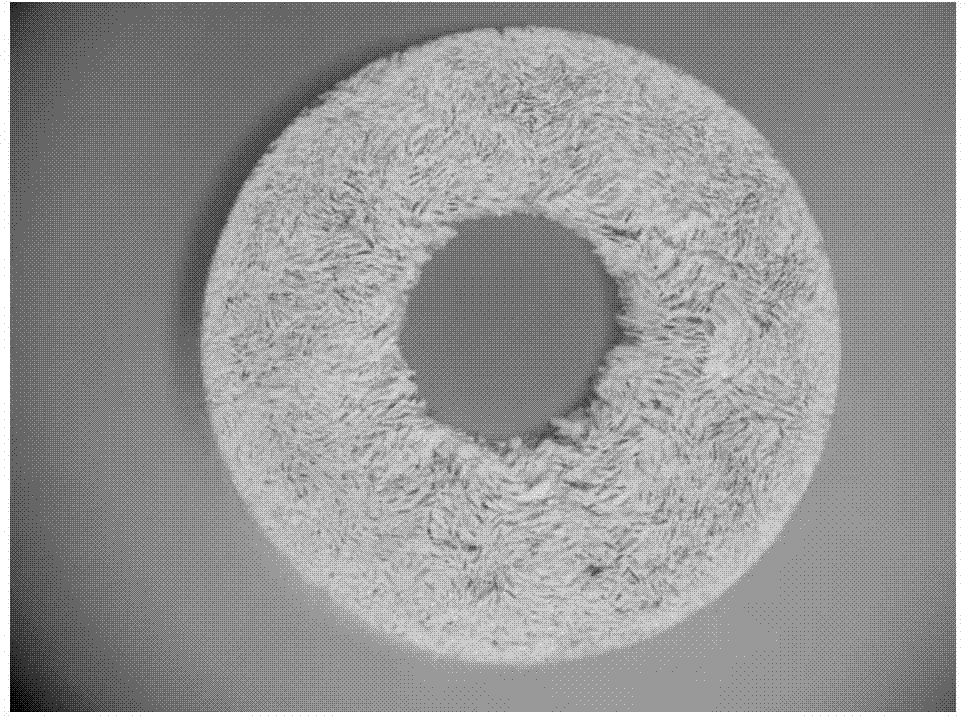

Image

Examples

Embodiment 1

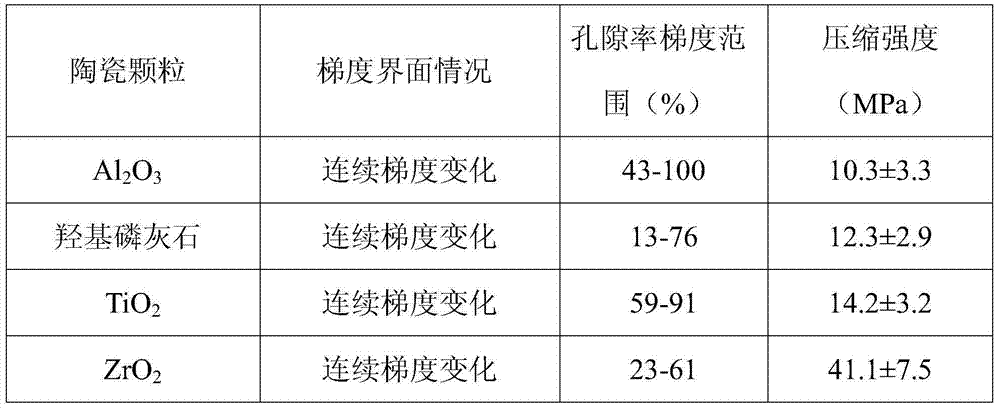

[0040] 20ml Al 2 o 3 Add the powder into 80ml of distilled water and mix evenly to obtain a volume concentration of 20% Al 2 o 3 Suspension; take 90g Al 2 o 3 Suspension, add 7g sodium polyacrylate and 3g polyvinyl alcohol into Al 2 o 3 In the suspension, mix evenly to obtain Al 2 o 3 slurry; Al 2 o 3The slurry is injected into a cylindrical mold with a heat transfer material on the bottom surface and an insulating material on the side, and then the mold injected with the slurry is centrifuged at 3500rpm for 12h on a centrifuge, and then the bottom of the mold is immersed in a methanol liquid cold source at -60°C and cooled. Maintain centrifugal rotation; Al 2 o 3 After the slurry was completely frozen, it was taken out and placed in an environment with a pressure of 200Pa to dry under low pressure to obtain a gradient porous Al 2 o 3 ceramic preform; the gradient porous Al 2 o 3 Ceramic preforms are sintered at a temperature of 1700°C to produce Al 2 o 3 Grad...

Embodiment 2

[0042] Add 30ml of hydroxyapatite powder into 70ml of distilled water, and mix evenly to obtain a hydroxyapatite suspension with a volume concentration of 30%; take 88g of hydroxyapatite suspension, mix 8g of sodium polyacrylate and 4g of carboxymethyl The cellulose is added to the hydroxyapatite ceramic suspension, and mixed evenly to obtain a hydroxyapatite ceramic slurry; the hydroxyapatite slurry is injected into a cylindrical mold with a heat transfer material on the bottom surface and an insulating material on the side, and then Centrifuge the mold injected with the slurry at 2000rpm for 4 hours on a centrifuge, then immerse the bottom of the mold in a liquid cold source of ethanol at -30°C and maintain the centrifugal rotation; after the hydroxyapatite slurry is completely frozen, take it out and place it under a pressure of The gradient porous hydroxyapatite ceramic preform is obtained by drying under low pressure in an environment of 0 Pa; the gradient porous hydroxyap...

Embodiment 3

[0044] 10ml TiO 2 Add the powder into 90ml distilled water and mix evenly to obtain TiO with a volume concentration of 10%. 2 Suspension; by mass percentage, take 93g TiO 2 Suspension, add 5g sodium dodecylbenzenesulfonate and 2g carboxymethyl cellulose to TiO 2 In the suspension, mix evenly to get TiO 2 slurry; the TiO 2 The slurry is injected into a cylindrical mold with a heat transfer material on the bottom and an insulating material on the side, and then the mold injected with the slurry is centrifuged at 500 rpm for 1 hour, and then the bottom of the mold is immersed in a mixture of liquid nitrogen and ethanol at -90°C In a cold source and kept in centrifugal rotation; TiO 2 After the slurry is completely frozen, take it out, place it in an environment with a pressure of 400Pa and dry it under low pressure to obtain a gradient porous TiO 2 ceramic preform; the gradient porous TiO 2 The ceramic preform is sintered at a temperature of 1300°C to obtain TiO 2 Gradient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com