Method for preparation of bone hydroxyapatite-imitating bone repair material

A technology for imitating bone hydroxyapatite bone and hydroxyapatite is applied in the field of preparing bone imitating hydroxyapatite bone repair material and preparing nano-gradient porous structure hydroxyapatite bone repair material, and can solve the problem of degradation rate of bone repair material. Tissue crawling replacement rate mismatch, material biological activity and mechanical properties decreased, bone defect repair ability decreased, etc., to achieve the effect of excellent osteogenic activity, easy industrial production, and reduced brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

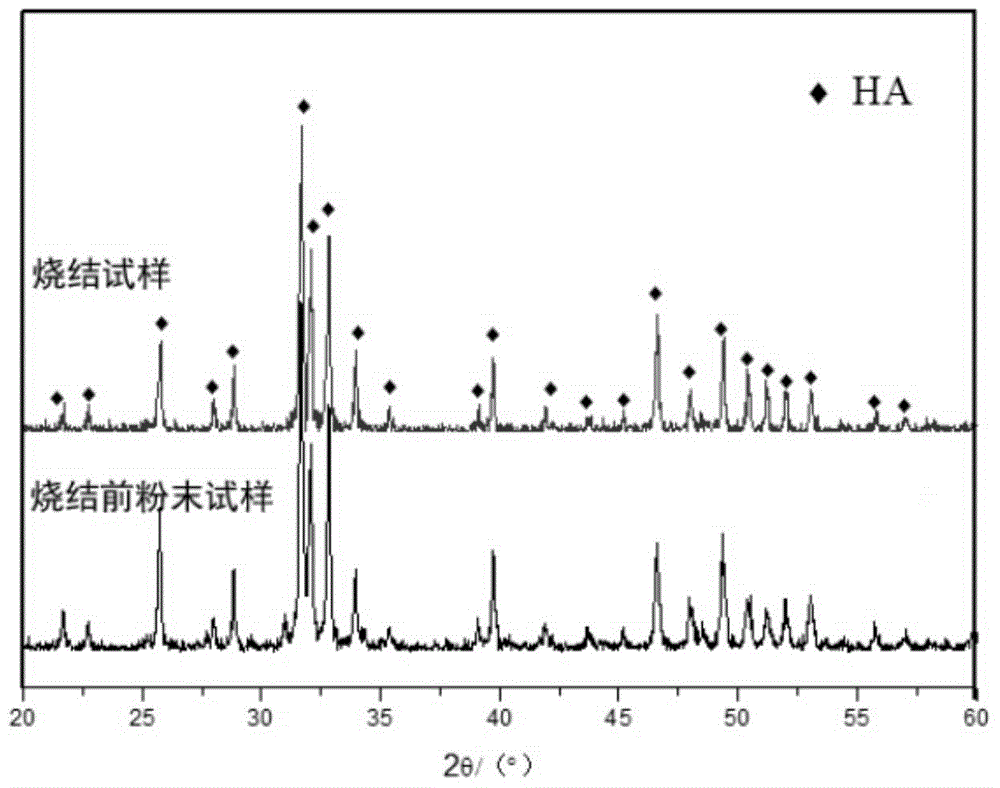

Image

Examples

Embodiment 1

[0024] A method for preparing a nanoscale bone-like gradient porous hydroxyapatite bone repair material by spark plasma sintering, specifically comprising the following steps:

[0025] 1) The hydroxyapatite ceramic powder with a purity of ≧97% and a particle size of 100nm and NH with a particle size of 100-500μm for analytical purity 4 HCO 3 The powders were mixed in the mixer for 120 minutes to obtain two mixed powders (mixed A powder and mixed B powder). Among them, the hydroxyapatite ceramic powder in the mixed A powder and the NH 4 HCO 3The mass percent of the powder is 85%:15%, and the hydroxyapatite ceramic powder and NH in the mixed B powder 4 HCO 3 The mass percentage of powder is 55%: 45%;

[0026] 2) Put the mixed powder obtained in step (1) into a stainless steel mold. Among them, the mixed A powder is put into the outer layer, and the mixed B powder is put into the inner layer. Under the unidirectional pressure of 100MPa, cold press molding is carried out, a...

Embodiment 2

[0031] A method for preparing a nanoscale bone-like gradient porous hydroxyapatite bone repair material by spark plasma sintering, specifically comprising the following steps:

[0032] 1) Combine hydroxyapatite ceramic powder with a purity of ≧97% and a particle size of 100nm and analytically pure NH 4 HCO 3 The powders were mixed in the mixer for 120 minutes according to the mass fraction percentage of 65%:35%, and the mixed powders were divided into two parts (mixed C powder and mixed D powder). Among them, the NH in the mixed C powder 4 HCO 3 The powder is sieved through a standard sieve with a particle size of 100-300 μm, and the NH in the mixed D powder 4 HCO 3 The powder is sieved through a standard sieve with a particle size of 300-500 μm;

[0033] 2) Put the mixed powder obtained in step (1) into a stainless steel mold. Among them, the mixed C powder is put into the outer layer, and the mixed D powder is put into the inner layer. Under the unidirectional pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com