Preparation method of gradient porous bioceramic scaffold

A bioceramic, gradient porous technology, applied in medical science, prosthesis, etc., can solve the problems of weak bearing capacity of porous ceramic stents, difficult to customize production for patients, etc., and achieve the effect of improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

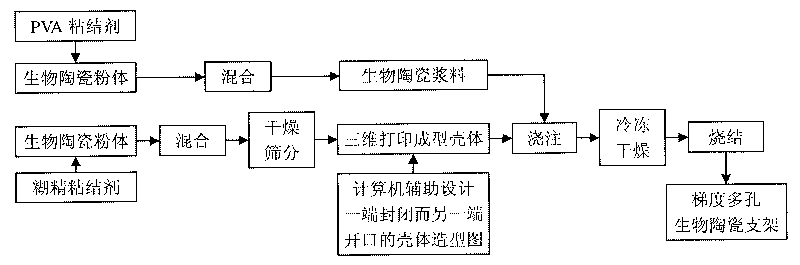

Method used

Image

Examples

Embodiment 1

[0035] (1.1) 5% dextrin by mass percentage is mixed with 95% hydroxyapatite bioceramic powder by mass percentage, and deionized water is added according to the solid-liquid ratio of 1:2 to make ceramic slurry, and the ceramic The slurry is placed in a ball mill tank, ball milled for 8 hours and mixed evenly, after drying, the bioceramic powder mixture with a diameter of less than 200 μm is screened out with an 80-mesh sieve for later use;

[0036] (1.2) Use computer-aided design software to design a shell shape drawing with one end closed and the other open;

[0037] (1.3) Use the bioceramic powder mixture obtained in step (1.1) as a raw material, use deionized water as a bonding aid, and use a 3D printer to print out a 3D shell according to the shell-shaped solid model designed in step (1.2). , after the water is dry, take out the three-dimensional shell, and clean up the excess powder that is not bonded in the three-dimensional shell.

[0038] (1.4) Adopt the polyvinyl alco...

Embodiment 2

[0042] (2.1) The dextrin of 15% by mass percentage is mixed with the tricalcium phosphate bioceramic powder of 85% by mass percentage, and according to the solid-liquid ratio of 1:2, add deionized water to make ceramic slurry, this ceramic slurry The material is placed in a ball mill tank, and ball milled for 12 hours to mix evenly. After drying, a bioceramic powder mixture with a diameter of less than 200 μm is screened out with an 80-mesh sieve for subsequent use;

[0043] (2.2) Use computer-aided design software to design a shell shape drawing with one end closed and the other open;

[0044] (2.3) Using the bioceramic powder mixture obtained in step (2.1) as a raw material, using deionized water as a bonding aid, and according to the shell-shaped solid model designed in step (2.2), use a 3D printer to print out a 3D shell , after the water is dry, take out the three-dimensional shell, and clean up the excess powder that is not bonded in the three-dimensional shell.

[0045...

Embodiment 3

[0049] (3.1) 10% by mass percentage of dextrin is mixed with 90% by mass percentage of silicon nitride bioceramic powder, and deionized water is added according to a solid-liquid ratio of 1:2 to make a ceramic slurry, and the ceramic slurry The material is placed in a ball mill tank, and ball milled for 10 hours to mix evenly. After drying, a bioceramic powder mixture with a diameter of less than 200 μm is screened out with a 80-mesh sieve for subsequent use;

[0050] (3.2) Use computer-aided design software to design a shell shape drawing with one end closed and the other open;

[0051] (3.3) Use the bioceramic powder mixture obtained in step (3.1) as a raw material, use deionized water as a bonding aid, and use a 3D printer to print out a 3D shell according to the shell-shaped solid model designed in step (3.2). , after the water is dry, take out the three-dimensional shell, and clean up the excess powder that is not bonded in the three-dimensional shell.

[0052] (3.4) Usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com