Method for forming titanium oxide film and titanium electrolytic capacitor

a technology of titanium oxide film and electrolytic capacitor, which is applied in the direction of electrolytic capacitor, solid-state diffusion coating, superimposed coating process, etc., can solve the problems of large leakage current, short life of the capacitor, high cost of tetrafluorocarbon, etc., and achieves small leakage current, high dielectric constant, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

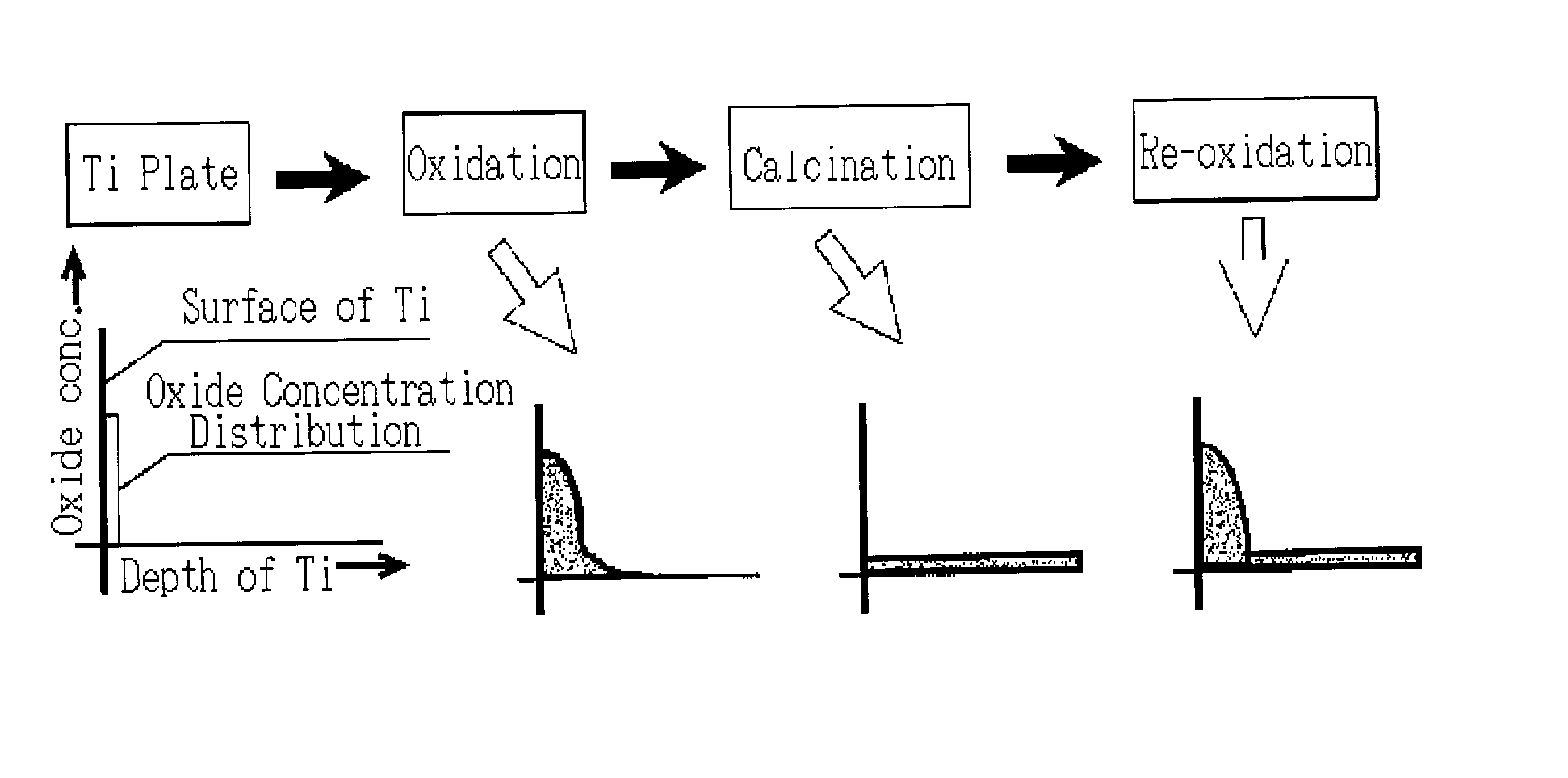

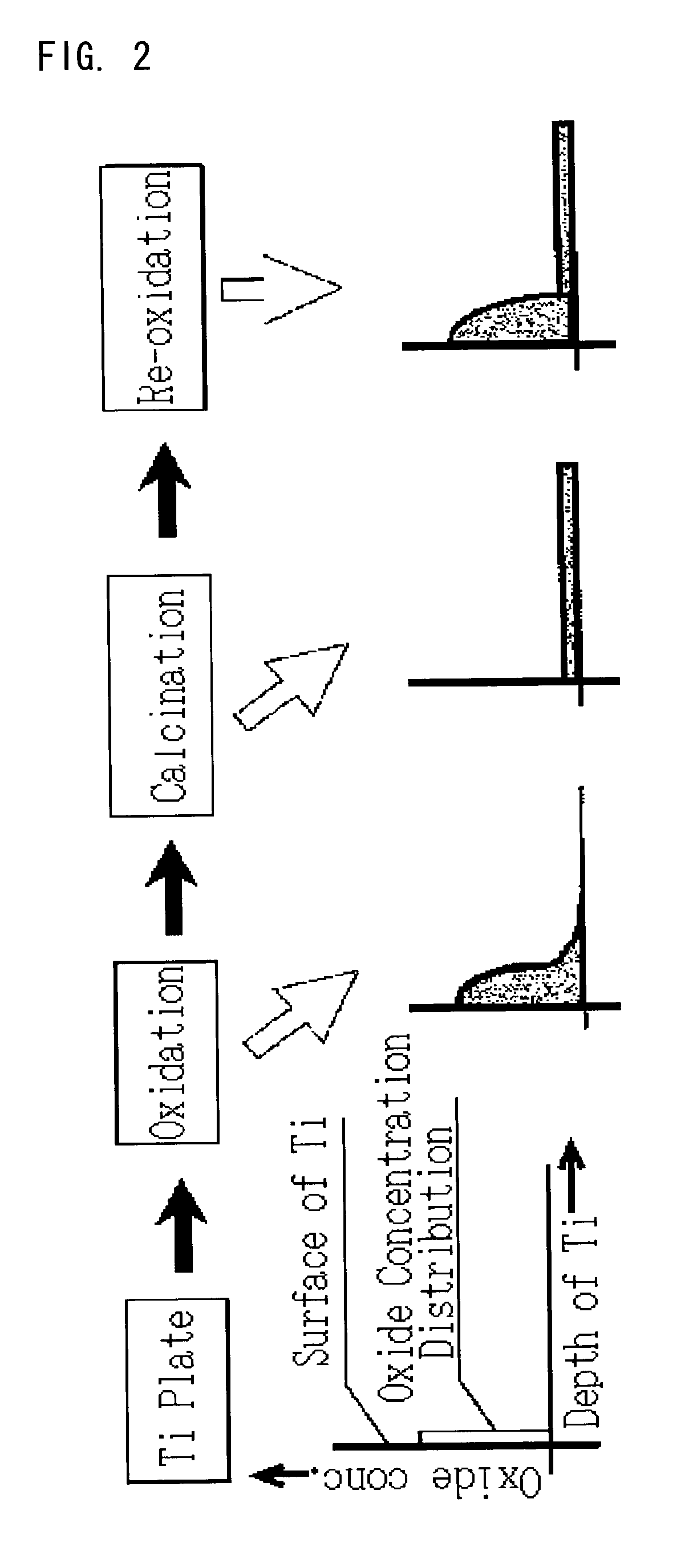

[0072] A metal titanium plate was heated in oxygen at 700.degree. C. for 2 hours, thereby obtaining an oxide film having a thickness of 400 nm. Subsequently, the plate was subjected to calcination in vacuum of approximately 1.times.10.sup.-3 Pa at 800.degree. C. for 2 hours, thereby removing the oxide film. The metal titanium plate was used as an electrode, and a voltage of 30 V was applied in an aqueous solution of ammonium adipate (150 g / L) for 5 minutes, thereby obtaining an oxide film. With respect to the resultant oxide film, evaluation of insulation property and measurement of capacitance were made. The results are shown in Table 1.

example 2

[0073] Substantially the same procedure as in Example 1 was repeated except that a metal titanium plate was heated in oxygen at 600.degree. C. for 2 hours, thereby obtaining an oxide film having a thickness of 100 nm. With respect to the resultant oxide film, evaluation of insulation property and measurement of capacitance were made. The results are shown in Table 1.

example 3

[0074] Substantially the same procedure as in Example 1 was repeated except that a metal titanium plate having an oxide film having a thickness of 400 nm was heated in vacuum at 800.degree. C. for 4 hours, thereby obtaining an oxide film. With respect to the resultant oxide film, evaluation of insulation property and measurement of capacitance were made. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com