Method for preparing calcium hydrophosphate micro-nanofiber conversion coating on pure-titanium surface

A calcium hydrogen phosphate micro-nano, conversion coating technology, applied in medical science, metal material coating technology, prosthesis and other directions, can solve the problems of no retrieval, no mention of calcium-containing conversion coating, difficult film formation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

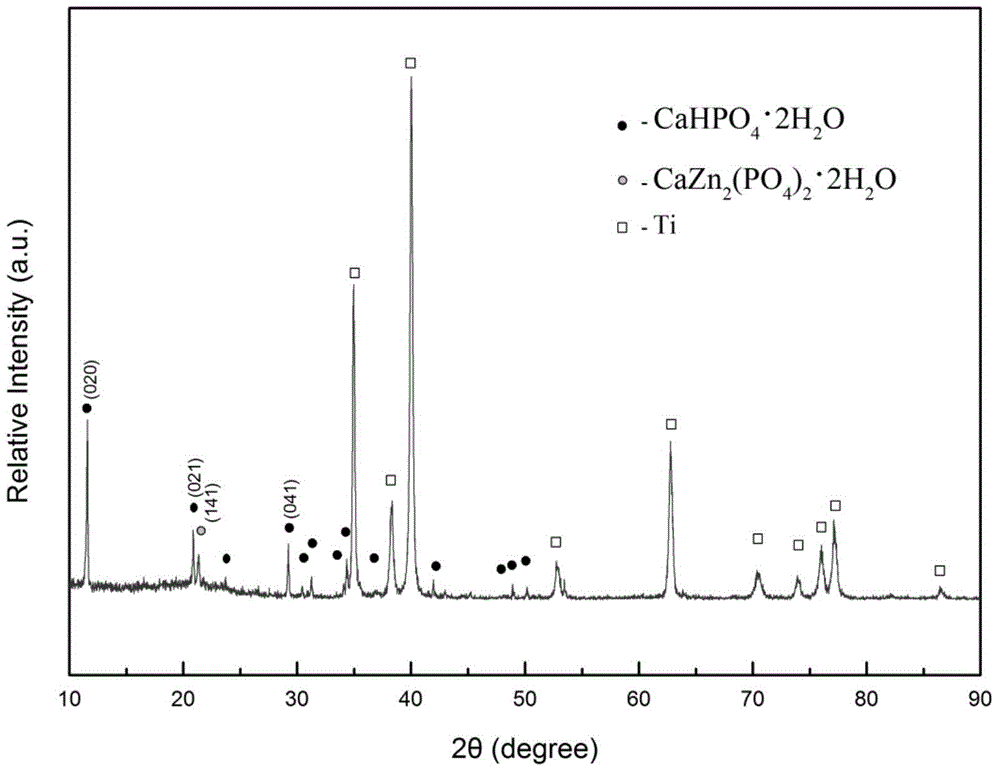

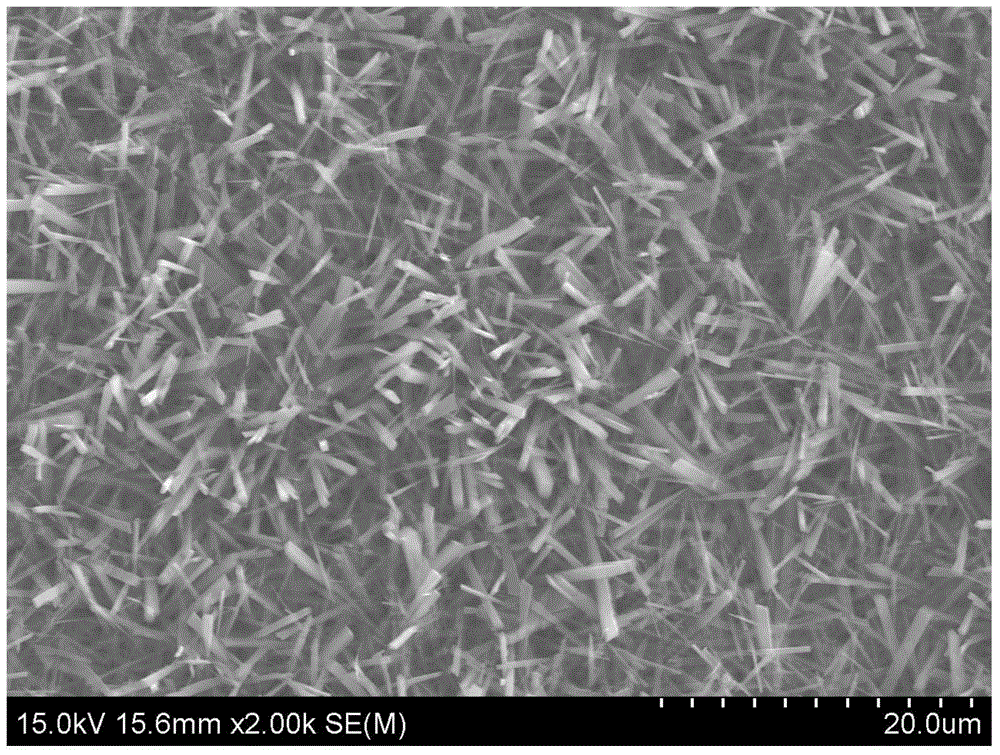

[0025] The preparation method of a kind of calcium hydrogen phosphate micro-nano fiber conversion film on the surface of pure titanium described in this embodiment, its specific steps are as follows:

[0026] (1) 85wt%H 3 PO 4 7ml / L, Ca(H 2 PO 4 ) 2 ·H 2 O 8g / L, Zn(H 2 PO 4 ) 2 2H 2 O 1.55g / L, NaNO 3 2g / L, NaNO 2 2g / L were mixed in sequence to prepare a chemical conversion solution.

[0027] (2) Add 5 g / L of reduced iron powder into the chemical conversion solution, leave it to mature at room temperature for 16 hours, and filter to obtain the supernatant.

[0028] (3) with H 3 PO 4 and NaOH to adjust the pH of the chemical transformation base solution to 5.00.

[0029] (4) Put the polished pure titanium substrate into 2wt% HF solution, activate it for 15s at room temperature, rinse the activated pure titanium substrate several times with deionized water, put the rinsed pure titanium substrate into the colloid In the titanium solution (titanium-containing phospha...

Embodiment 2

[0033] The preparation method of a kind of calcium hydrogen phosphate micro-nano fiber conversion film on the surface of pure titanium described in this embodiment, its specific steps are as follows:

[0034] (1) 85wt%H 3 PO 4 8ml / L, Ca(H 2 PO 4 ) 2 ·H 2 O 9g / L, Zn(H 2 PO 4 ) 2 2H 2 O 2g / L, NaNO 3 2.5g / L, NaNO 2 2.5g / L were mixed in sequence to prepare a chemical conversion solution.

[0035] (2) Add 6 g / L of reduced iron powder into the chemical transformation solution, leave it to mature at room temperature for 18 hours, and filter to get the supernatant.

[0036] (3) with H 3 PO 4 and NaOH to adjust the pH of the chemical transformation base solution to 5.00.

[0037] (4) Put the polished pure titanium substrate into 2wt% HF solution, activate it for 15s at room temperature, rinse the activated pure titanium substrate several times with deionized water, put the rinsed pure titanium substrate into the colloid In the titanium solution (titanium-containing phosp...

Embodiment 3

[0041] (1) 85wt%H 3 PO 4 10ml / L, Ca(H 2 PO 4 ) 2 ·H 2 O 15g / L, Zn(H 2 PO 4 ) 2 2H 2 O 4g / L, NaNO 3 3g / L, NaNO 2 4g / L mixed in sequence to prepare a chemical conversion solution.

[0042] (2) Add 7 g / L of reduced iron powder into the chemical conversion solution, leave it to mature at room temperature for 24 hours, and filter to obtain the supernatant.

[0043] (3) with H 3 PO 4 and NaOH to adjust the pH of the chemical transformation base solution to 5.00.

[0044] (4) Put the polished pure titanium substrate into 2wt% HF solution, activate it for 15s at room temperature, rinse the activated pure titanium substrate several times with deionized water, put the rinsed pure titanium substrate into the colloid In the titanium solution (titanium-containing phosphate colloidal solution), the surface is adjusted for 30s at room temperature.

[0045] (5) Coupling the pure titanium sample treated in step (4) with pure iron, first acting in a 250w ultrasonic field for 20 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com