Method for forming graded multi-hole shape on titanium surface

A technique of hierarchical porosity and morphology, which is applied in the field of hierarchical porous morphology on the surface of titanium, can solve the problems of energy consumption, limited to micron-scale pores or only nano-scale pores, and the limitation of pore structure size changes, so as to improve biological activity, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

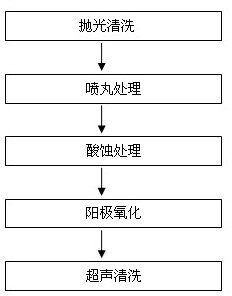

[0028] Embodiment 1. Method 1 of forming hierarchical porous morphology on titanium surface

[0029] A After the pure titanium sample is finely ground and polished, it is ultrasonically cleaned once with absolute ethanol, acetone, and deionized water, each time for 15 minutes. After degreasing and cleaning, dry it.

[0030] B Use 100 to 150 mesh glass balls to carry out shot peening treatment on the surface of the titanium sample. The shot peening pressure is 0.30 to 0.60Mpa. The surface is uniform blue-gray, ultrasonically cleaned with acetone and deionized water, and dried.

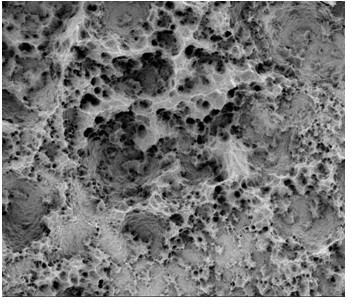

[0031] C The sample after the shot peening treatment is etched with oxalic acid with a concentration of 10wt%. nanoscale pore structure.

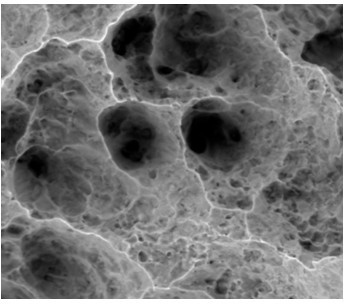

[0032] D The pure titanium sample after the shot blasting and acid etching treatment is treated by anodic oxidation method, the titanium sample is used as the anode for anodic oxidation treatment, and the graphite plate is used as the cathode, and the electrochemic...

Embodiment 2

[0034] Embodiment 2. Method two of forming hierarchical porous morphology on titanium surface

[0035] A After the pure titanium sample is finely ground and polished, it is ultrasonically cleaned once with absolute ethanol, acetone, and deionized water, each time for 20 minutes. After degreasing and cleaning, dry it.

[0036] B Use 100 to 150 mesh glass balls to carry out shot peening treatment on the surface of the titanium sample. The shot peening pressure is 0.30 to 0.60Mpa. The surface is uniform blue-gray, ultrasonically cleaned with acetone and deionized water, and dried.

[0037] C The sample after shot peening treatment is etched with oxalic acid with a concentration of 5wt%. nanoscale pore structure.

[0038] D The pure titanium sample after the shot blasting and acid etching treatment is treated by anodic oxidation method, the titanium sample is used as the anode for anodic oxidation treatment, and the graphite plate is used as the cathode, and the electrochemical ...

Embodiment 3

[0040] Embodiment 3. Method three for forming hierarchical porous morphology on titanium surface

[0041] A After the pure titanium sample is finely ground and polished, it is ultrasonically cleaned twice with absolute ethanol, acetone, and deionized water in sequence, each time for 10 minutes. After degreasing and cleaning, dry it.

[0042] B Use 100 to 150 mesh glass balls to carry out shot peening treatment on the surface of the titanium sample, the shot peening pressure is 0.30 to 0.60Mpa, the spray gun and the titanium surface are axially 60°C during the shot peening process, the spray distance is 5cm, and the shot peening reaches the titanium sample The surface is uniform blue-gray, ultrasonically cleaned with acetone and deionized water, and dried.

[0043]C The sample after the shot peening treatment is etched with oxalic acid with a concentration of 15wt%. nanoscale pore structure.

[0044] D The pure titanium sample after the shot blasting and acid etching treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com