Method for solidly supporting molybdenum disulfide through porous titanium oxide film

A technology of titanium oxide film and molybdenum disulfide, which is applied in ion implantation plating, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problem of reducing the friction coefficient of metal titanium surface, and achieve the effect of reducing the friction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The metal titanium sheet is subjected to ultrasonic and pickling treatment, pulse anodized in an inorganic aqueous solution containing fluoride ions for 4 hours, and then ultrasonically dried after heat treatment at 450°C; both the oxidized titanium sheet and the pickled titanium sheet are placed in magnetron sputtering In the film coating system, the sputtering time is set to 10min, the sputtering temperature is set to 100°C, the sputtering power is 50W, 100W, 150W, 200W, 300W, and the vacuum degree of the background is 5×10 -4 Pa, the pre-sputtering time is 180s, and the argon pressure is 1Pa. After vacuuming, heating, pre-sputtering, pressure regulation, sputtering, cooling to 60°C and taking out. Sample preparation under different sputtering powers is completed.

Embodiment 2

[0024] The metal titanium sheet is subjected to ultrasonic and pickling treatment, pulse anodized in an inorganic aqueous solution containing fluoride ions for 4 hours, and then ultrasonically dried after heat treatment at 450°C; both the oxidized titanium sheet and the pickled titanium sheet are placed in magnetron sputtering In the spray coating system, the sputtering power is set to 100W, the sputtering temperature is set to 100°C, the sputtering time is 10min, 20min, 30min, and the vacuum degree of the back is 5×10 -4 Pa, the pre-sputtering time is 180s, and the argon pressure is 1Pa. After vacuuming, heating, pre-sputtering, pressure regulation, sputtering, cooling to 60°C and taking out. The sample preparation under different sputtering times is completed.

Embodiment 3

[0026] The metal titanium sheet is subjected to ultrasonic and pickling treatment, pulse anodized in an inorganic aqueous solution containing fluoride ions for 4 hours, and then ultrasonically dried after heat treatment at 450°C; both the oxidized titanium sheet and the pickled titanium sheet are placed in magnetron sputtering In the film coating system, the sputtering power is set at 100W, the sputtering time is 10min, the sputtering temperature is set at room temperature, 100°C, 200°C, 300°C, 400°C, and the vacuum degree of the back is 5×10 -4 Pa, the pre-sputtering time is 180s, and the argon pressure is 1Pa. After vacuuming, heating, pre-sputtering, pressure regulation, sputtering, cooling to 60°C and taking out. Sample preparation at different sputtering temperatures is complete.

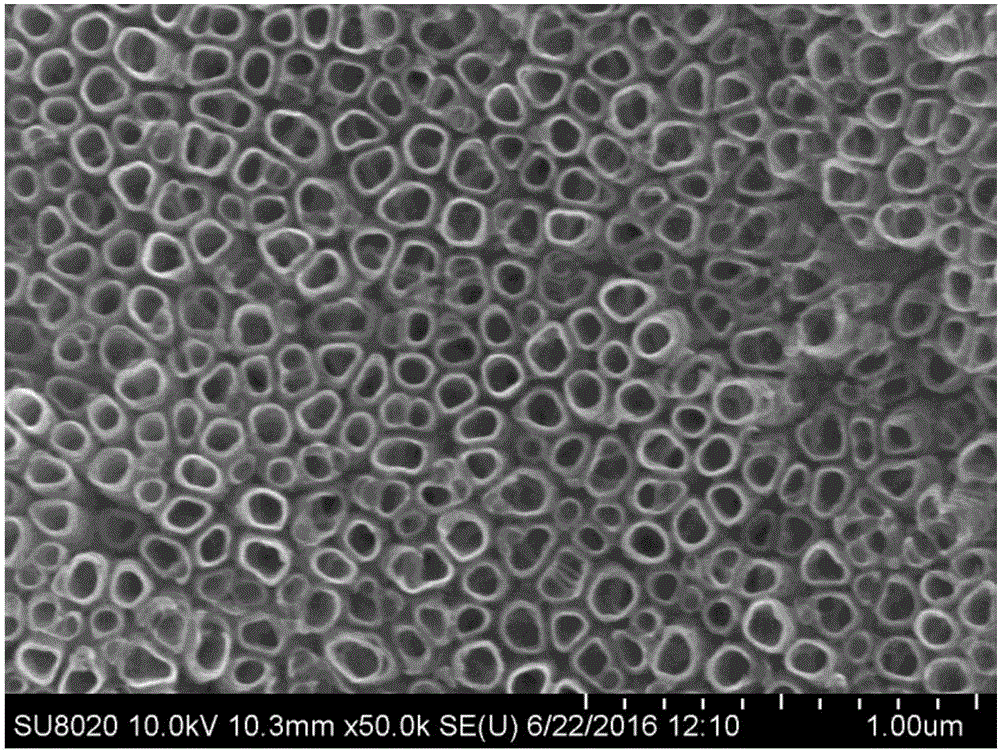

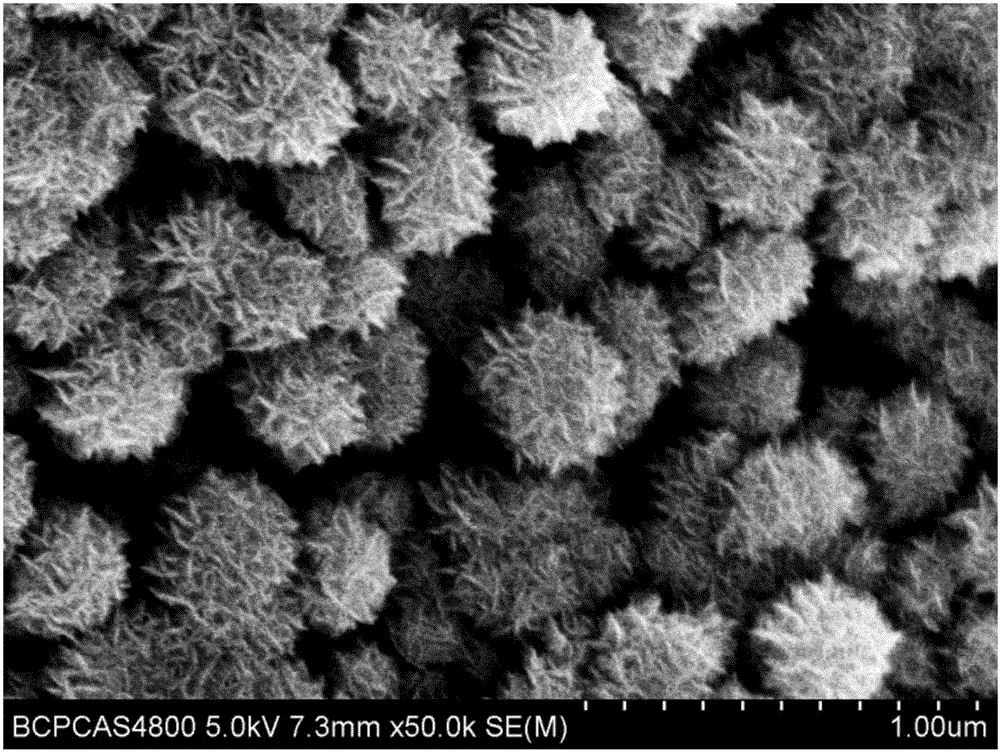

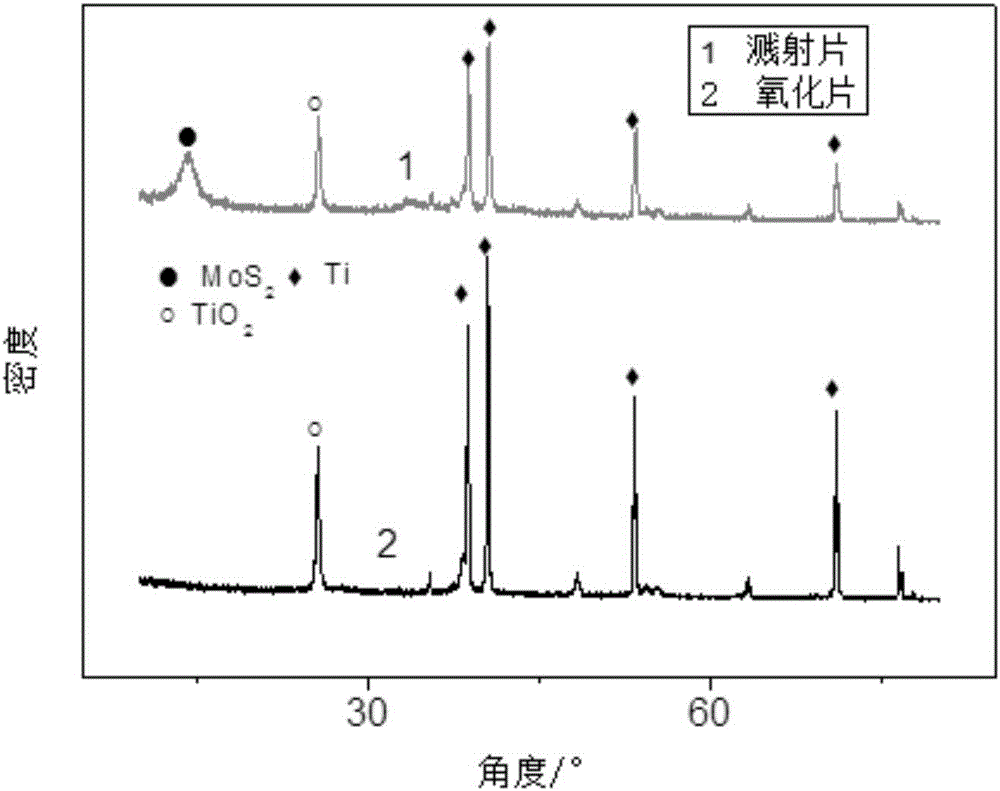

[0027] Above-mentioned embodiment repeatability is good, and the similar technical effect that obtains, the titanium dioxide SEM figure of oxidation voltage 20V sees figure 1 , the SEM image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com