Titanium or titanium alloy having TiO2-HA surface coating and preparation method thereof

A surface coating and titanium alloy technology, which is applied in the field of biomedical material preparation, can solve the problems of low bonding strength between the coating and the substrate, and achieve the effects of improving bonding strength, increasing deposition speed, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

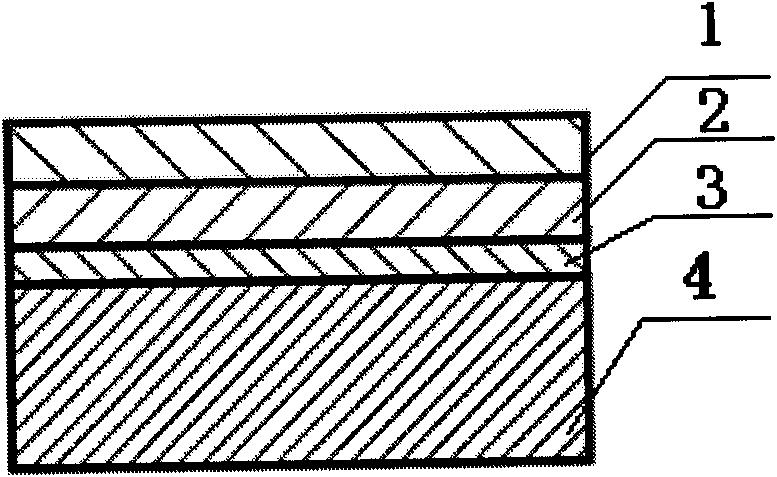

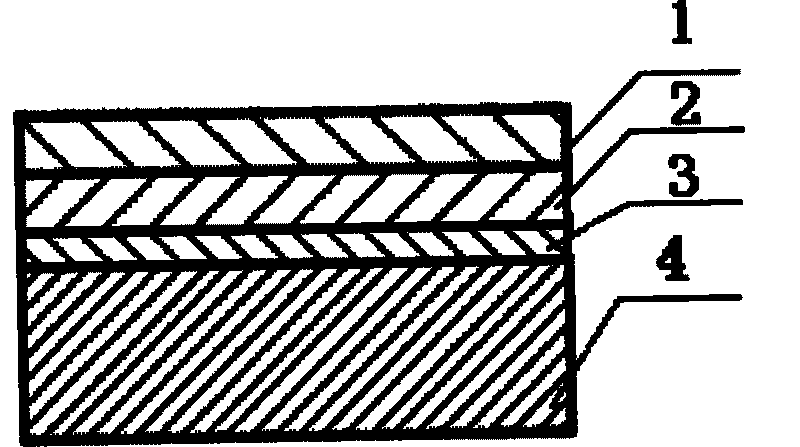

Image

Examples

Embodiment 1

[0025] Soak the titanium alloy sample in a NaOH solution with a concentration of 5mol / L and a temperature of 60°C for 72 hours, then wash it with distilled water, dry it in an incubator at 40°C for 24 hours, and then raise the temperature to 600°C at a speed of 10°C / min , keep warm for 10 minutes. Then, a layer of TiO was prepared on the titanium alloy with a rotation speed of 2500r / min and a rotation time of 10s on the desktop homogenizer. 2 The coating was dried at 150°C for 15 minutes, then kept in a vacuum furnace at 500°C for 15 minutes, and then cooled in the furnace. Repeat the same steps to apply TiO 2 -HA coating and HA coating. The last heat treatment was carried out in a vacuum furnace at 750°C for 1h. Cool to room temperature and take out to obtain titanium alloy-TiO 2 -HA gradient coating medical materials. The interface bonding strength reaches 32MPa.

Embodiment 2

[0027] Soak the titanium alloy sample in a NaOH solution with a concentration of 5mol / L and a temperature of 60°C for 36 hours, then wash it with distilled water, dry it in an incubator at 40°C for 24 hours, and then raise the temperature to 500°C at a speed of 10°C / min , keep warm for 30 minutes. Then prepare a layer of TiO on the titanium alloy with a rotation speed of 2000r / min and a rotation time of 10s on the desktop homogenizer. 2 The coating was dried at 150°C for 15 minutes, then kept in a vacuum furnace at 500°C for 15 minutes, and then cooled in the furnace. Repeat the same steps to apply TiO 2 -HA coating and HA coating. The last heat treatment was carried out in a vacuum furnace at 750°C for 1h. Cool to room temperature and take out to obtain titanium alloy-TiO 2 -HA gradient coating medical materials. The interface bonding strength reaches 31MPa.

Embodiment 3

[0029] Soak the titanium alloy sample in a NaOH solution with a concentration of 8mol / L and a temperature of 60°C for 48 hours, then wash it with distilled water, dry it in an incubator at 40°C for 24 hours, and then raise the temperature to 500°C at a speed of 10°C / min , keep warm for 1 hour. Then, a layer of TiO was prepared on the titanium alloy with a rotation speed of 1500r / min and a rotation time of 10s on the desktop homogenizer. 2 The coating was dried at 150°C for 15 minutes, then kept in a vacuum furnace at 500°C for 15 minutes, and then cooled in the furnace. Repeat the same steps to apply TiO 2 -HA coating and HA coating. The last heat treatment was carried out in a vacuum furnace at 750°C for 1h. Cool to room temperature and take out to obtain titanium alloy-TiO 2 -HA gradient coating medical materials. The interface bonding strength reaches 35MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com