Method for coating surface of titanium materials and application of coating composite materials

A technology of surface coating and composite materials, applied in coatings, medical science, prostheses, etc., can solve problems such as implant failure, cell inflammation, necrosis, etc., and achieve the effect of promoting cell adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Titanium sheet (10×10×1mm 3 ) were ultrasonically cleaned with deionized water, anhydrous acetone and absolute ethanol in sequence for 30 min each.

[0041] (2) Put the cleaned titanium sheet into 5mol / L NaOH solution, and treat at 80°C for 24h. The titanium sheet was taken out, washed gently with deionized water, and dried in an oven at 40°C.

[0042](3) Put the dried titanium sheet into the furnace at 10°C / min, raise the temperature to 600°C, heat-preserve for 1h, and take out the titanium sheet after the temperature in the furnace is naturally cooled to room temperature.

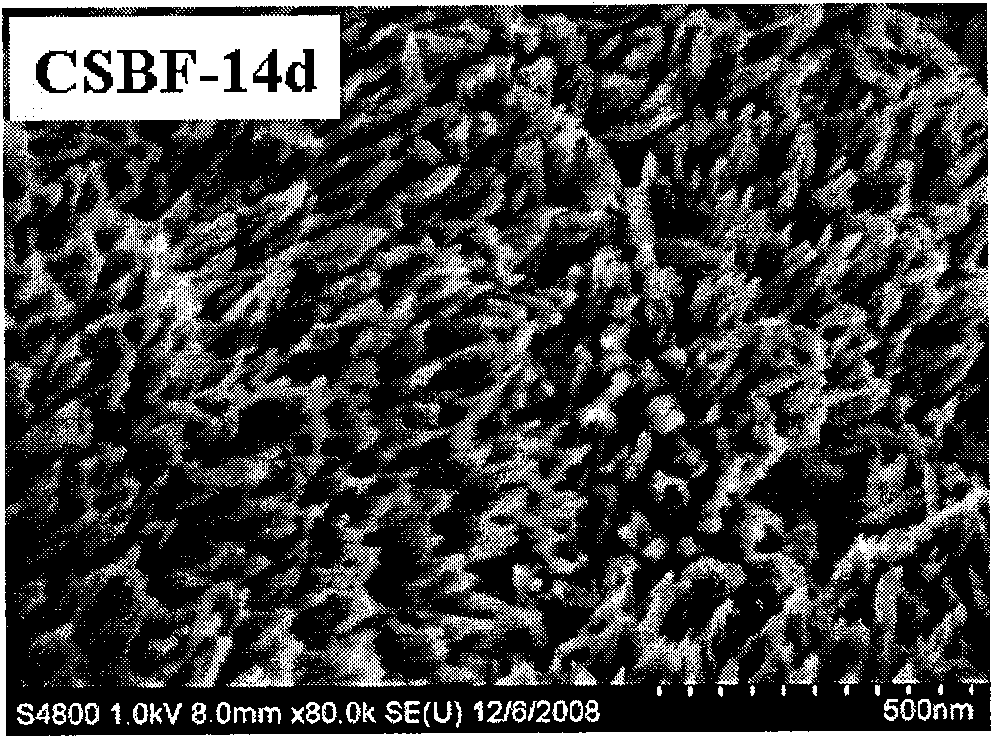

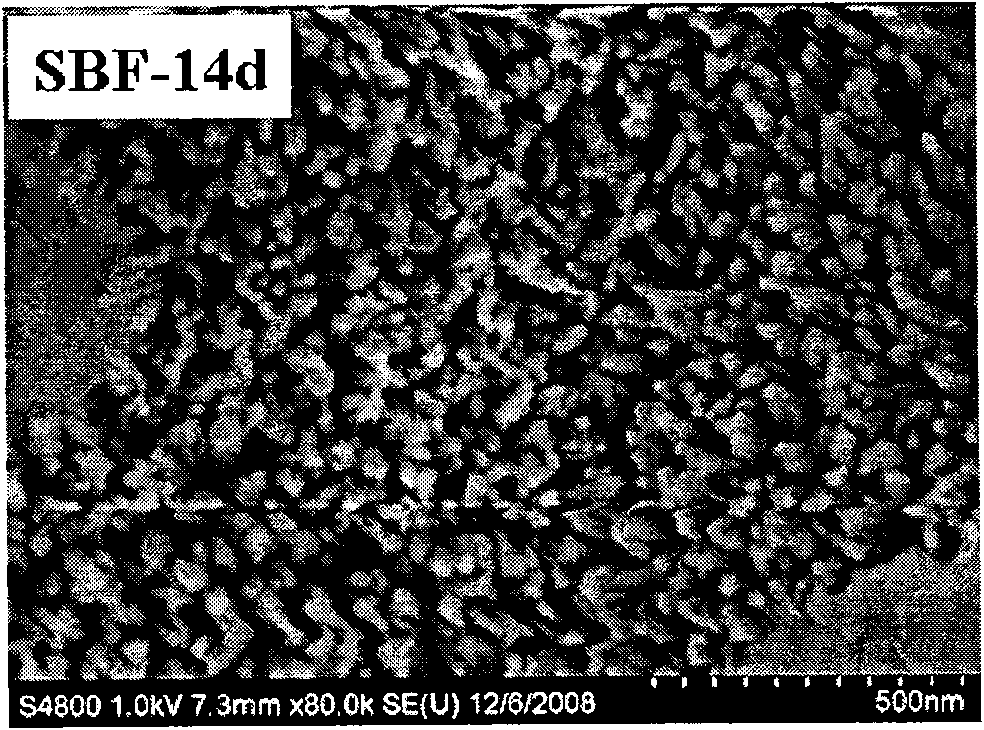

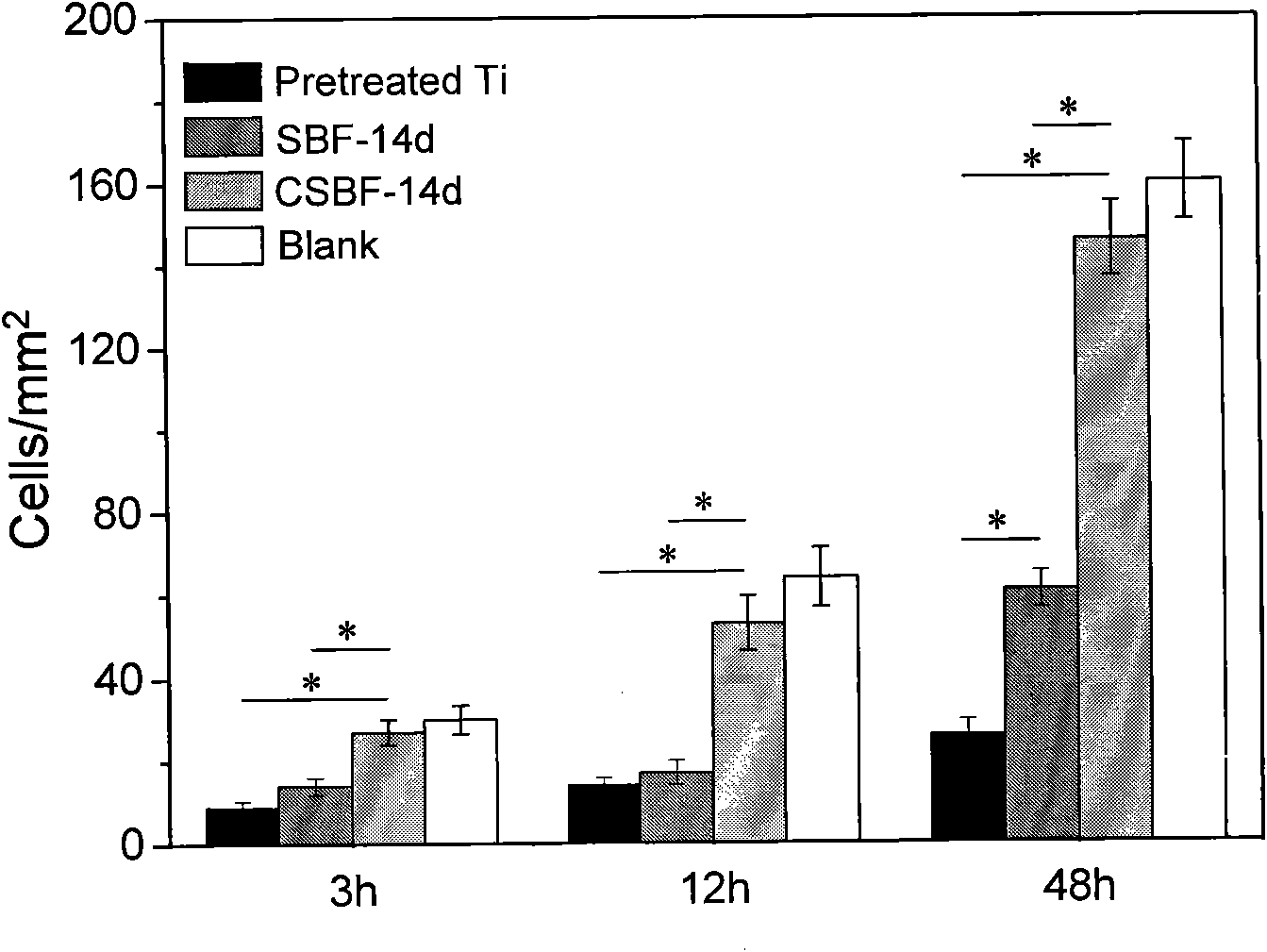

[0043] (4) Prepare a biomimetic solution (1.5×CSBF) containing 1.5 times of recombinant collagen, weigh the corresponding components in turn, dissolve them in deionized water one by one, adjust the pH to 7.4 with 1M hydrochloric acid, and dilute to 1L.

[0044] (5) Place the titanium sheet treated in step (1) in a 12-well plate, add 5 mL of 1.5×CSBF solution to each well, and let it stand at ...

Embodiment 2

[0047] (1) Titanium sheet (10×10×1mm 3 ) were ultrasonically cleaned with deionized water, anhydrous acetone and absolute ethanol in sequence for 30 min each.

[0048] (2) Put the cleaned titanium sheet into 5mol / L NaOH solution, and treat at 80°C for 24h. The titanium sheet was taken out, washed gently with deionized water, and dried in an oven at 40°C.

[0049] (3) Put the dried titanium sheet into the furnace at 10°C / min, raise the temperature to 600°C, heat-preserve for 1h, and take out the titanium sheet after the temperature in the furnace is naturally cooled to room temperature.

[0050] (4) Prepare a biomimetic solution (1.5×CSBF) containing 1.5 times of recombinant collagen, weigh the corresponding components in turn, dissolve them in deionized water one by one, adjust the pH to 7.4 with 1M hydrochloric acid, and dilute to 1L.

[0051] (5) Place the titanium sheet treated in step (1) in a 12-well plate, add 5 mL of 1.5×CSBF solution to each well, and let it stand at...

Embodiment 3

[0054] (1) Titanium sheet (10×10×1mm 3 ) were ultrasonically cleaned with deionized water, anhydrous acetone and absolute ethanol in sequence for 30 min each.

[0055] (2) Put the cleaned titanium sheet into 5mol / L NaOH solution, and treat at 80°C for 24h. The titanium sheet was taken out, washed gently with deionized water, and dried in an oven at 40°C.

[0056] (3) Put the dried titanium sheet into the furnace at 10°C / min, raise the temperature to 600°C, heat-preserve for 1h, and take out the titanium sheet after the temperature in the furnace is naturally cooled to room temperature.

[0057] (4) Prepare a biomimetic solution (1.5×CSBF) containing 1.5 times of recombinant collagen, weigh the corresponding components in turn, dissolve them in deionized water one by one, adjust the pH to 7.4 with 1M hydrochloric acid, and dilute to 1L.

[0058] (5) Place the titanium sheet treated in step (1) in a 12-well plate, add 5 mL of 1.5×CSBF solution to each well, and let it stand at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com