Method for preparing black titanium oxide coating on titanium surface

A technology for titanium metal and titanium oxide is applied in the field of preparing micro-arc oxidation coating on the surface of titanium metal, which can solve the problems of high energy consumption, high cost and complicated preparation process, and achieve the effects of low energy consumption, simple operation and uniform surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

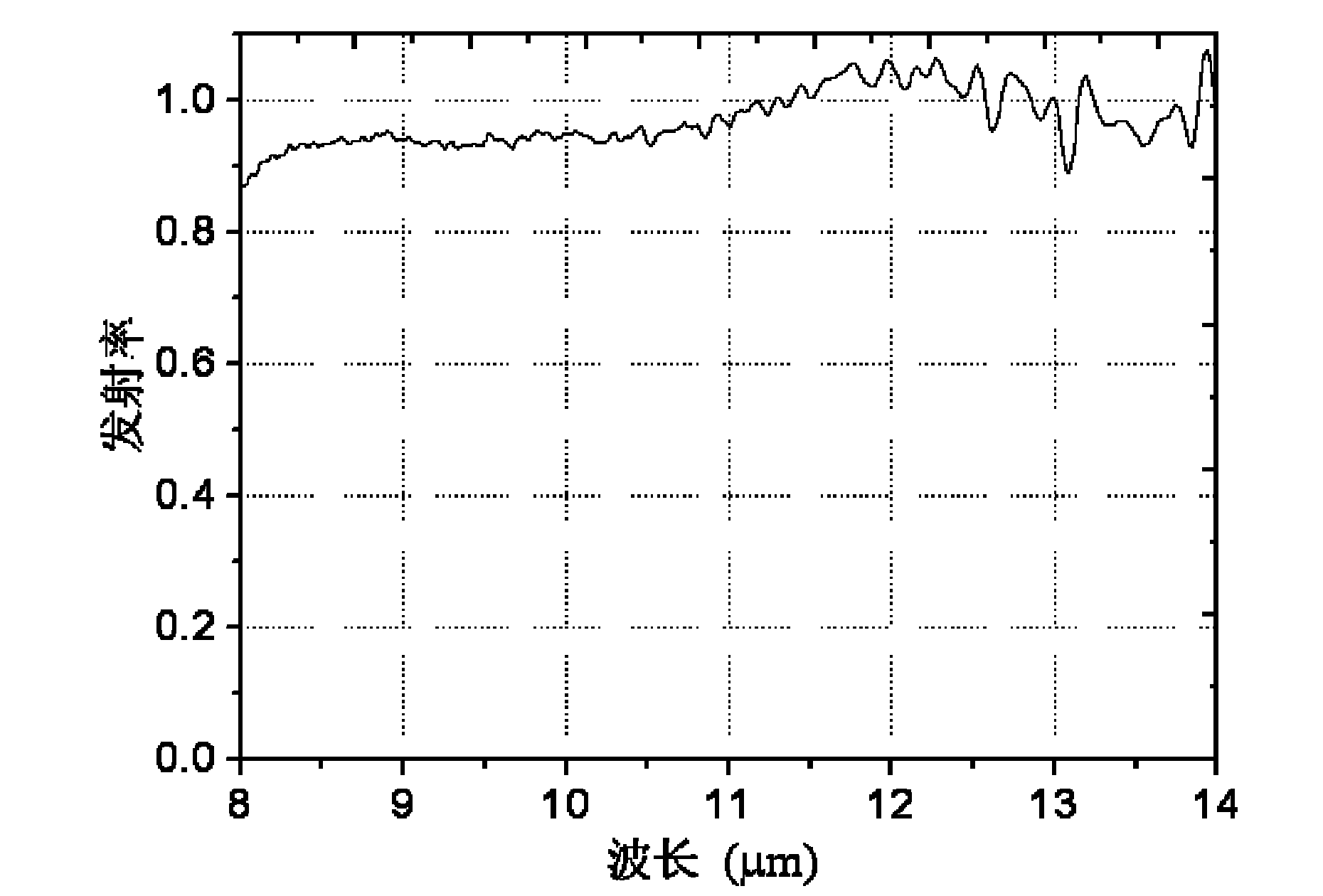

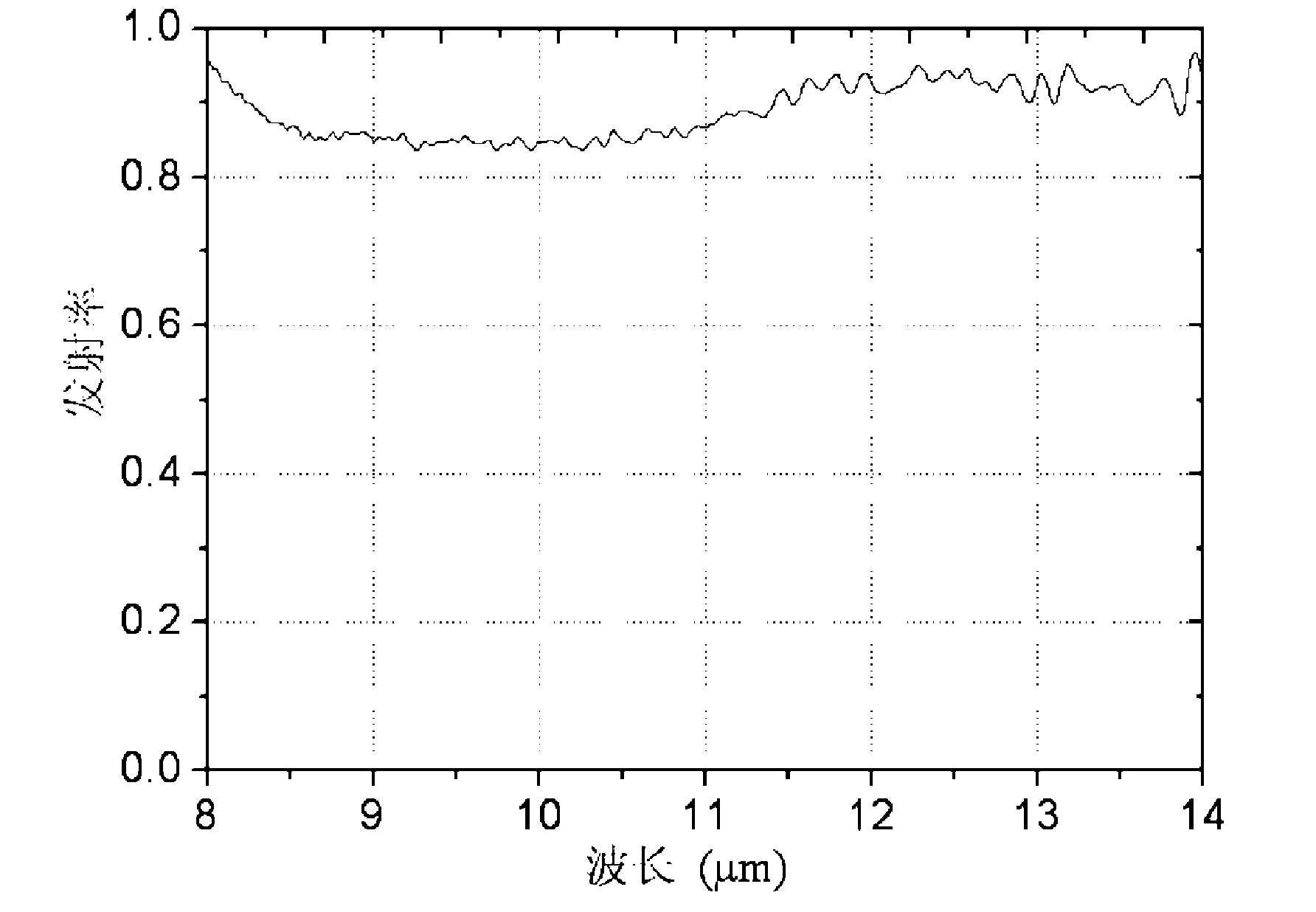

Image

Examples

specific Embodiment approach 1

[0014] Embodiment 1: The method for preparing a black titanium oxide coating on the surface of titanium metal in this embodiment is realized through the following steps: one, carry out degreasing treatment on titanium metal parts; two, adopt high-voltage high-frequency bipolar pulse power supply, with The titanium metal part is the anode, and the stainless steel is the cathode. Immerse the titanium metal parts and stainless steel in the micro-arc oxidation electrolyte, adjust the pulse parameters as pulse voltage 400-600V, frequency 400-800Hz, duty cycle 4%-20%, start the power supply Perform micro-arc oxidation for 10 to 200 minutes to prepare a black titanium oxide coating on the surface of titanium metal parts, wherein the micro-arc oxidation electrolyte is to add metal-containing vanadium with a mass concentration of 4 to 10 g / L in the alkaline electrolyte system Cationic vanadate is obtained, and the temperature of the electrolyte is controlled at 35-50°C during the micro-...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that the specific operation of degreasing the titanium metal parts in step 1 is: immerse the titanium metal parts in acetone, then ultrasonically clean them for 2 to 10 minutes, and then use After washing with ion water, let it dry naturally. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the titanium metal in the titanium metal part in step 2 is pure titanium, TC4 alloy, TA15 alloy, TC16 alloy, TB8 alloy or titanium-aluminum alloy. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

[0020] In this embodiment, pure titanium is TA1, TA2, TA3. Titanium aluminum alloy is TI-(45-46)Al-(6-9)Nb, Ti-(45-46)Al-(6-9)V, Ti3Al alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com