Modification method for titanium surface with osteogenic performance and antibacterial performance

A surface modification and performance technology, applied in the direction of prosthesis, vacuum evaporation plating, coating, etc., can solve the problem of not being able to achieve both osteogenesis and antibacterial, and achieve easy popularization and application, good controllability, and adhesion and growth-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (a) Use medical pure titanium as the base material, degrease the surface with acetone and install it in the furnace. Use a pulsed arc source, use pure silver and pure calcium as the cathode, and use an ordinary pencil (such as 2B) to coat a complete layer of calcium cathode. The carbon covering layer has a thickness greater than 200 nanometers, and then undergoes co-implantation of silver and calcium plasma immersion ions. Ion implantation adopts an ion implanter with two pulsed arc sources, and the two pulsed arc sources are controlled in linkage. The ion implantation process parameters are: the temperature of the vacuum chamber is 50-60°C, the vacuum degree is 3×E-3-4×E-3Pa, the implantation voltage is 30-40kV, the pulse width is 300-450μs, and the frequency is 5-7Hz. The processing time is 1.0h;

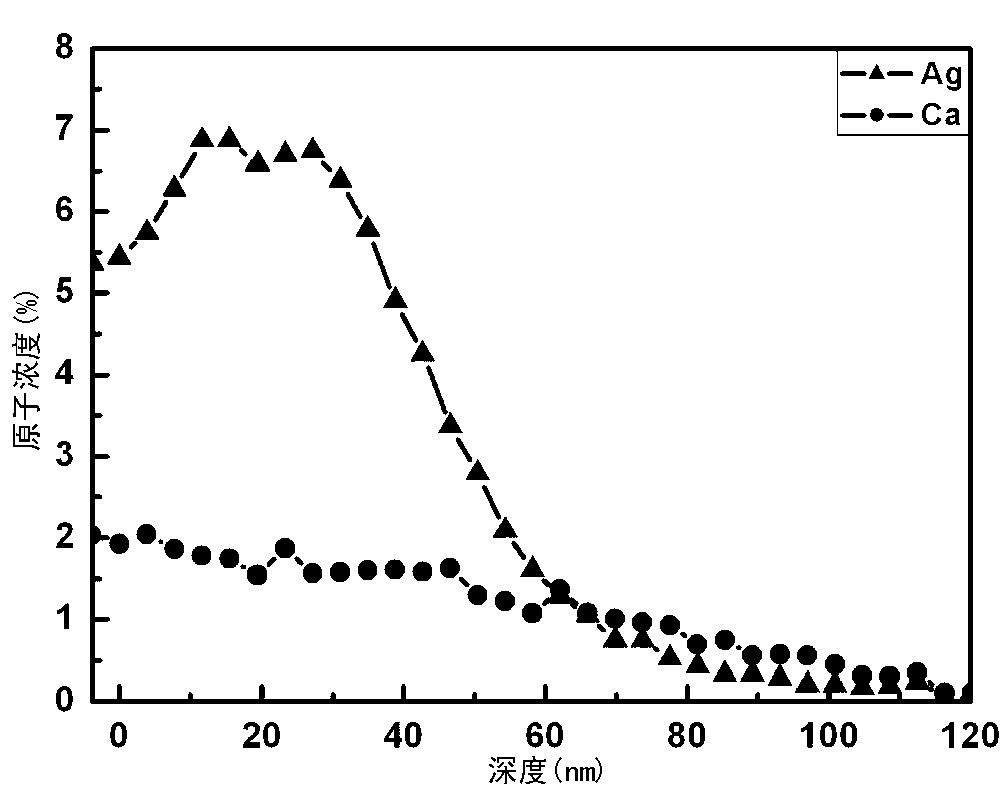

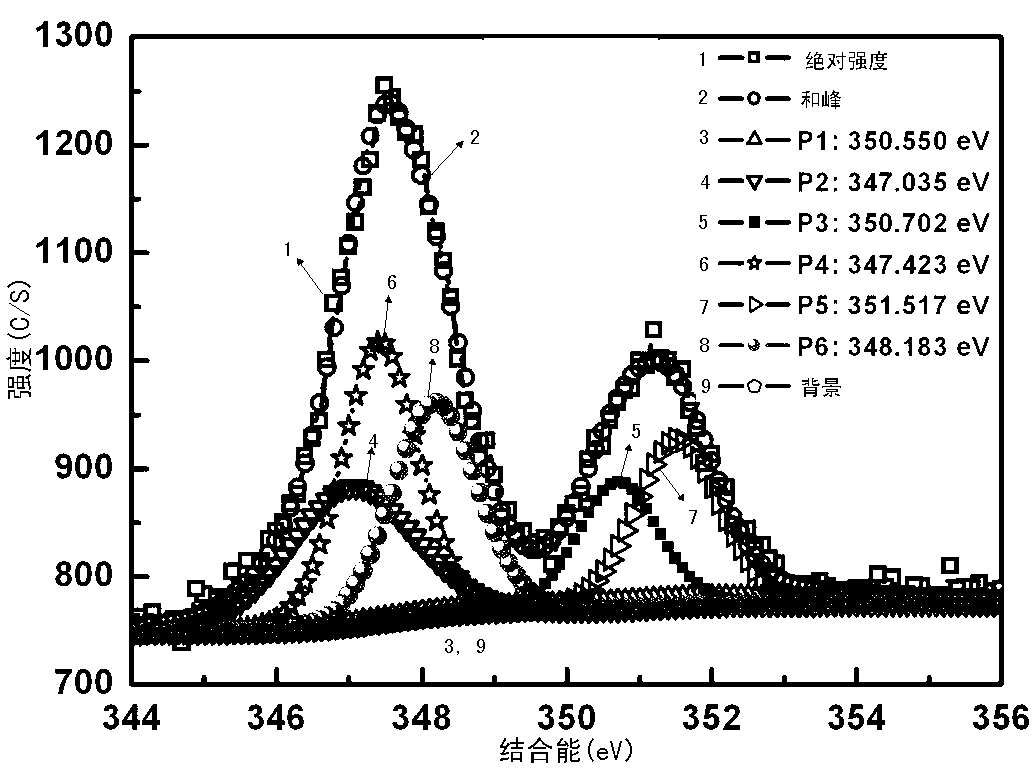

[0043] (b) X-ray photoelectron spectroscopy analysis (the instrument used is PHI 5802 of PE-PHI Company of the United States), shows that after ion implantation, silver an...

Embodiment 2

[0047] (a) Use medical pure titanium as the base material, degrease the surface with acetone and install it in the furnace. Use a pulsed arc source, use pure silver and pure calcium as the cathode, and use an ordinary pencil (such as 2B) to coat a complete layer of calcium cathode. The carbon covering layer has a thickness greater than 200 nanometers, and then undergoes co-implantation of silver and calcium plasma immersion ions. Ion implantation adopts an ion implanter with two pulsed arc sources, and the two pulsed arc sources are controlled in linkage. The ion implantation process parameters are: the temperature of the vacuum chamber is 20-40°C, the vacuum degree is 3×E-3-4×E-3Pa, the implantation voltage is 15-25kV, the pulse width is 500-600μs, and the frequency is 7-9Hz. The processing time is 0.5h;

[0048] (b) Scanning electron microscope observation shows that after ion implantation treatment, silver nanoparticles are formed on the surface of the material ( Figure ...

Embodiment 3

[0052] (a) Use medical pure titanium as the base material, degrease the surface with acetone and install it in the furnace. Use a pulsed arc source, use pure silver and pure calcium as the cathode, and use an ordinary pencil (such as 2B) to coat a complete layer of calcium cathode. The carbon covering layer has a thickness greater than 200 nanometers, and then undergoes co-implantation of silver and calcium plasma immersion ions. Ion implantation adopts an ion implanter with two pulsed arc sources, and the two pulsed arc sources are controlled in linkage. The ion implantation process parameters are: the temperature of the vacuum chamber is 30-50°C, the vacuum degree is 3×E-3-4×E-3Pa, the implantation voltage is 25-30kV, the pulse width is 400-550μs, and the frequency is 6-8Hz. The processing time is 2.0h;

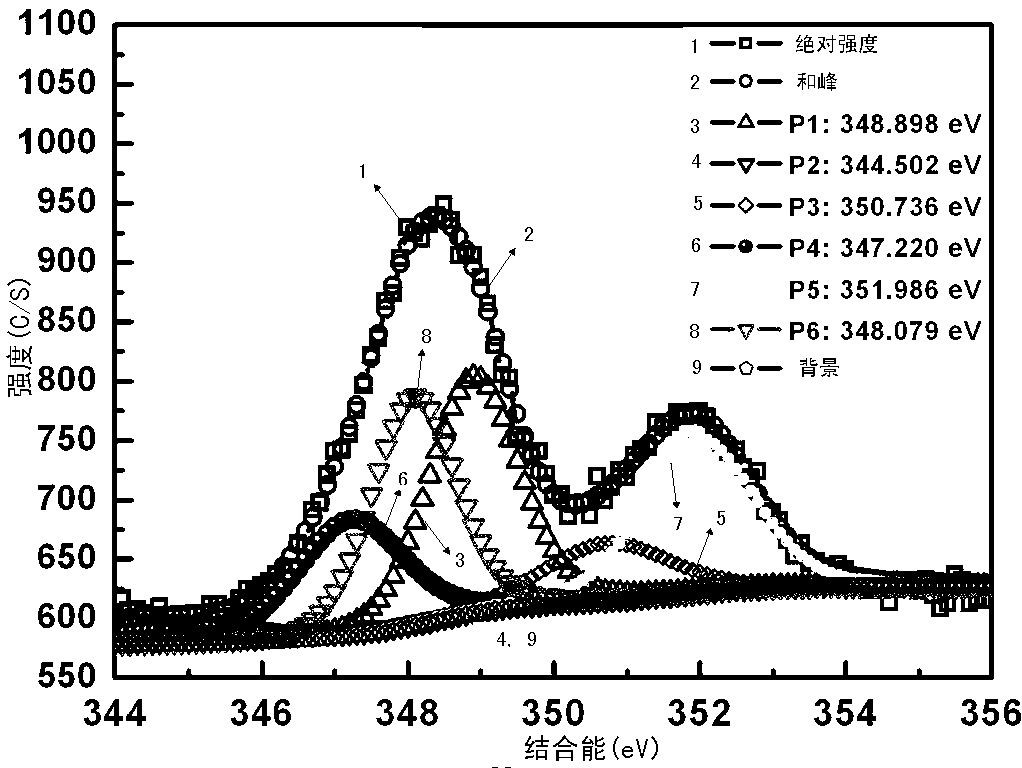

[0053] (b) X-ray photoelectron spectrum analysis (the instrument used is PHI 5802 of PE-PHI Company of the United States), which shows that after ion implantation, silver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com