Production method of black steel for 510L automobile frame

A production method and technology for automobile beams, applied in the field of sheet rolling, can solve the problems of large gap and unsatisfactory effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Coils 1 and 2 are produced according to the production method of 510L black skin steel for automobile frame. The chemical composition control is shown in Table 1, the rolling process parameters are shown in Table 2, and the mechanical properties of the coil are shown in Table 3.

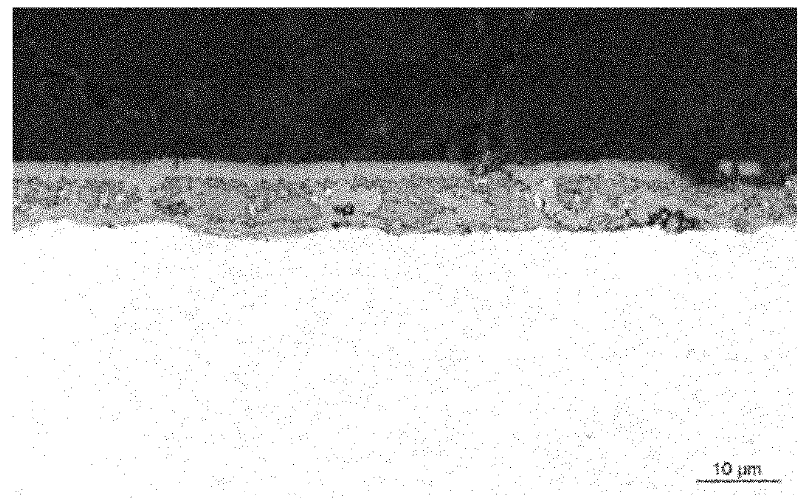

[0022] The oxide scale thicknesses of two rolls of 510L black steel for automobile frame are 8.1 and 8.5um respectively, and Fe in the oxide scale structure 3 o 4 The ratios of the scales are controlled at 80.5% and 84%, respectively, and the appearance of the surface oxide scale is shown in the attached Image 6 And attached Figure 7 shown. During the adhesive bending test, there is no peeling off of the iron oxide scale, which meets the stamping requirements. Figure 8 And attached Figure 9 shown.

[0023] Table 1 Coil Composition Control (Wt.%) Balance: Fe

[0024] steel number

C

Si

mn

P

S

als

Nb

1

0.106

0.15

1.2

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com