Fracturing conveying ground manifold system

A technology for manifold systems and pipelines, applied in pipeline systems, production fluids, boreholes/well components, etc., can solve problems such as severe elbow vibration, inconvenient installation, complex layout, etc., to improve operating efficiency, Efficient disassembly and assembly, and the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

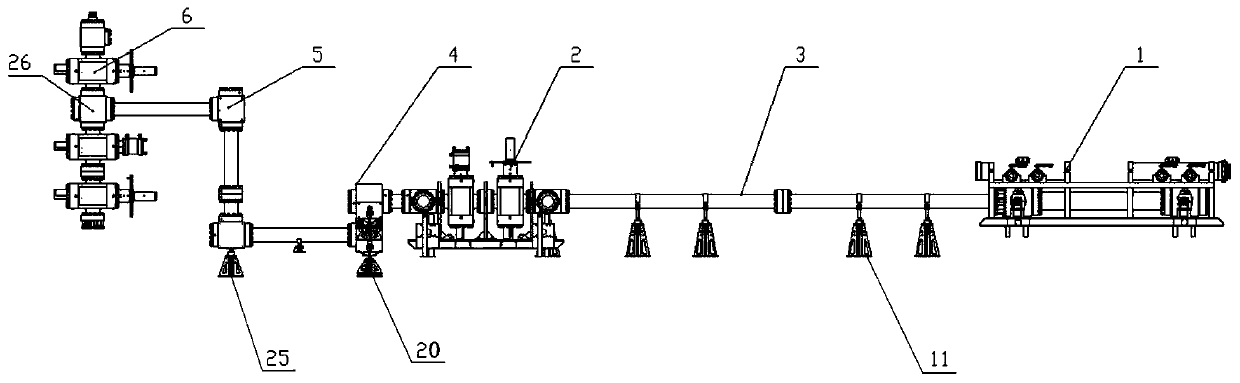

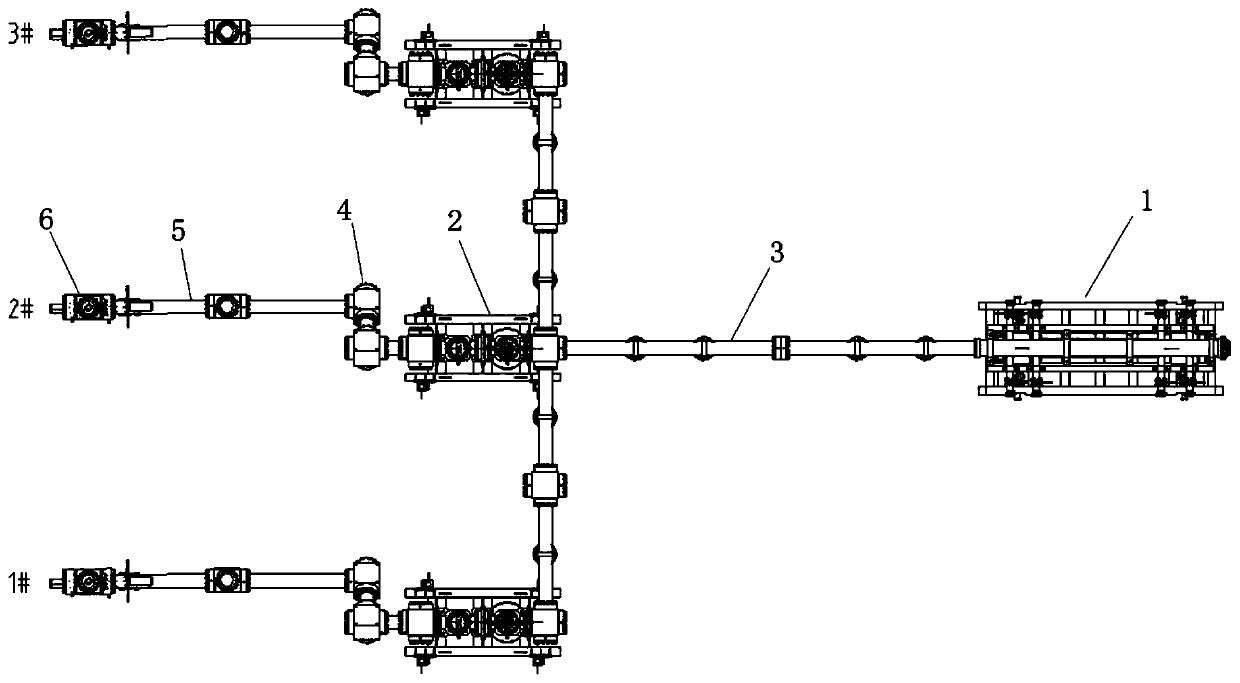

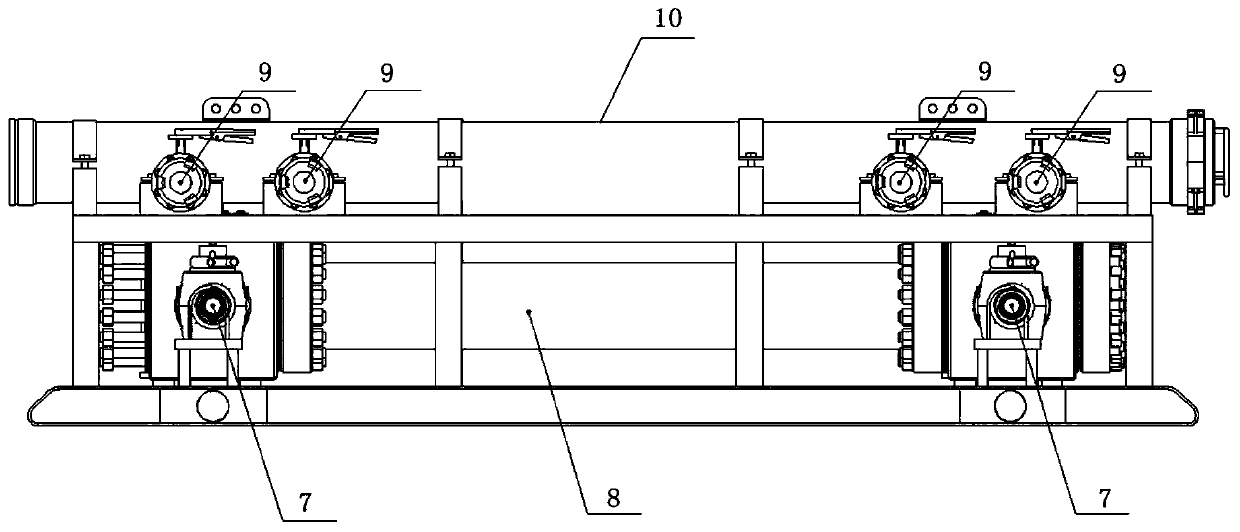

[0031] Such as Figures 1 to 5 As shown, a surface manifold system for fracturing delivery includes a fracturing tree 6, a high and low pressure manifold device 1, a high pressure flange delivery pipeline 3, a ground fracturing control manifold device 2, an offset flange mechanism 4 and a corner Pipeline 5, the high-low pressure manifold device 1 is linearly connected to the ground fracturing control manifold device 2 through the high-pressure flange delivery pipeline 3, and the ground fracturing control manifold device 2 is connected through the offset flange mechanism 4 and the corner pipeline 5 To realize the connection with the fracturing tree 6, the offset flange mechanism 4 and the corner pipeline 5 can realize the adjustment of different heights and directions between the ground fracturing control manifold device 2 and the fracturing tree 6. The high-pressure fluid channel is composed of a high-pressure and low-pressure manifold device 1, a high-pressure flange delivery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com