Tiny clamp capable of integrating clamping force sensor and clamping jaw displacement sensor

A technology of clamping force sensor and displacement sensor, which is applied in the field of micro-clamps, can solve the problems that the micro-clamps cannot measure the clamping force and jaw displacement, and cannot guarantee the parallel movement of the jaws, and achieve stable force reduction ratio and structure Simple, Small Size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

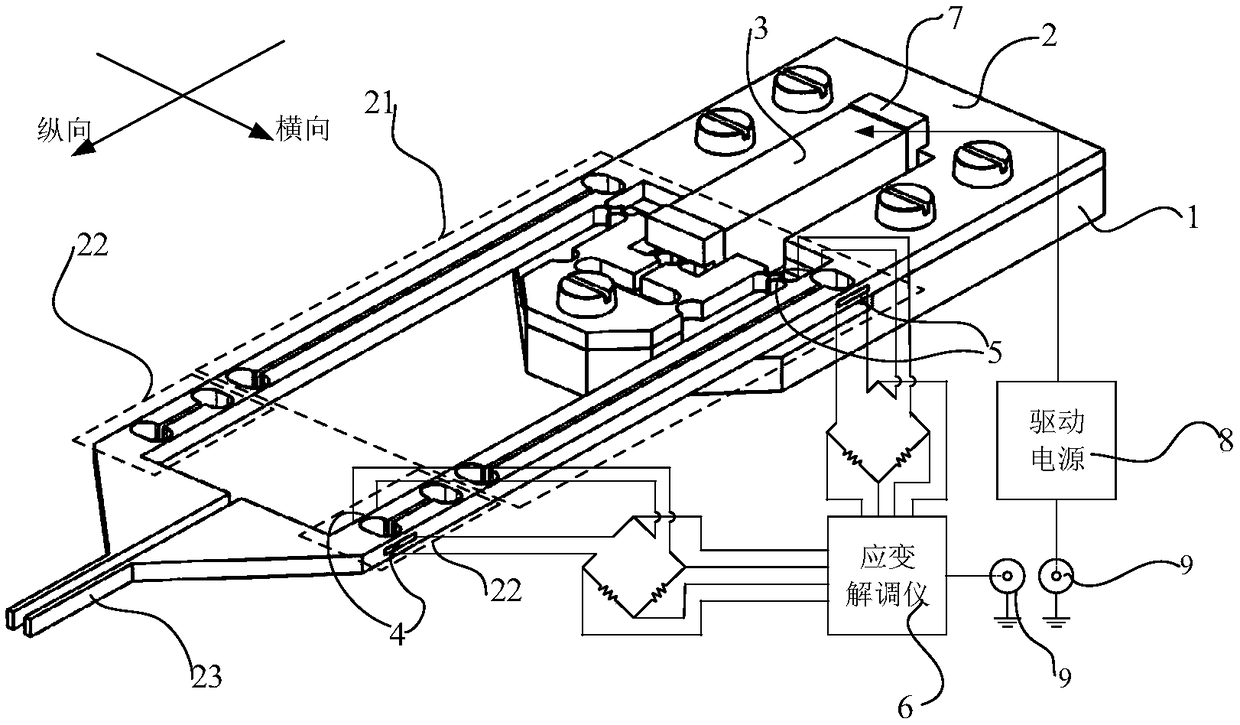

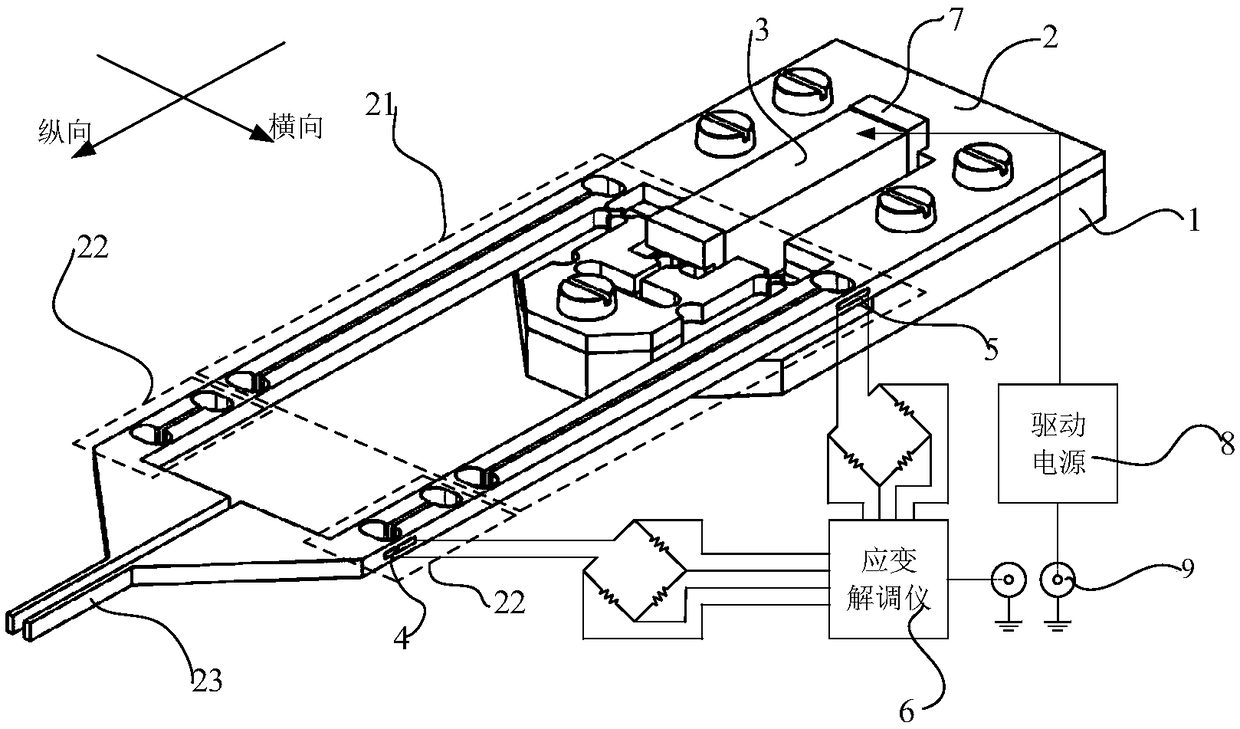

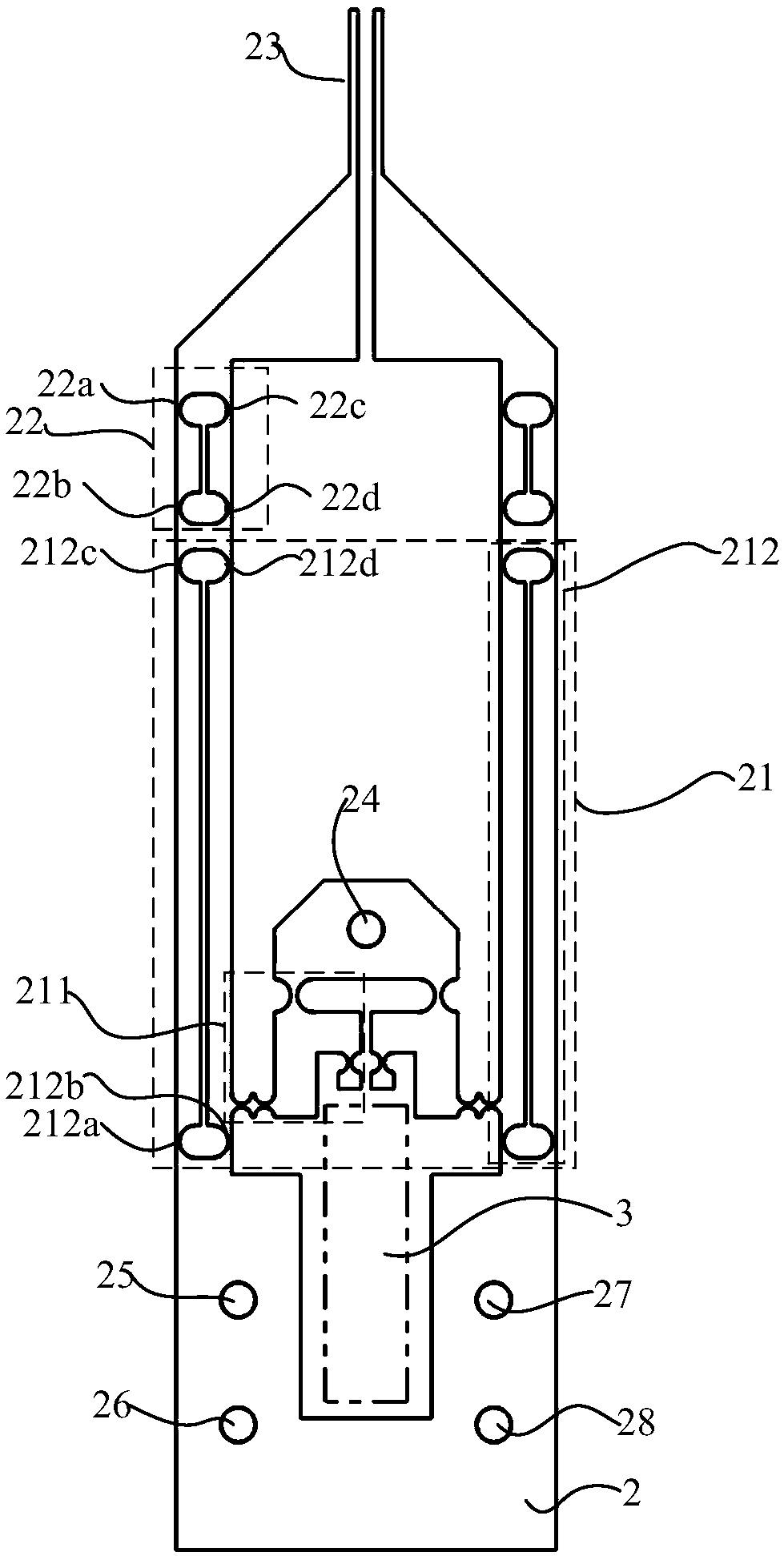

[0049] refer to Figure 1 to Figure 14 , the present invention provides a kind of micro gripper with integrated clamping force sensor and jaw displacement sensor, comprising: a base 1, a single-piece flexible mechanism 2 fixed on the base 1, and a single-piece flexible mechanism 2 installed on the single-piece flexible mechanism 2 The actuator 3 in the cavity, the controller, the strain interrogator 6 connected with the controller, and the clamping force sensor 4 and the jaw displacement sensor 5 connected with the strain interrogator 6, the single-chip flexible mechanism 2 includes Displacement amplifying mechanism 21, two clamping force sensing mechanisms 22 symmetrically arranged and two jaws 23 symmetrically arranged, the input stage 211 of the displacement amplifying mechanism 21 abuts against the actuator 3, the two displacement amplifying mechanisms 21 The output stage 212, the two clamping force sensing mechanisms 22 and the two clamping jaws 23 correspond one-to-one, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com