Engine pyrotechnics starting system

A starting system and engine technology, applied in the direction of machines/engines, mechanical equipment, gas turbine devices, etc., can solve the problems of low reliability of missile engines, inability to meet the rapid response of missiles, low efficiency, etc., and achieve the effect of improving sealing

Inactive Publication Date: 2013-12-11

HARBIN DONGAN ENGINE GRP

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The ignition system uses a coil and an ignition nozzle. In most cases, the starting fuel needs to be ignited first, and the small torch formed thereby ignites the main fuel. This type of ignition is relatively low reliability for bomb engines.

For small turbofan engines, the above-mentioned auxiliary engines are large in size, low in efficiency, long in engine start-up time, and relatively high in cost, which cannot meet the rapid response and reliable maneuverability requirements of missiles as weapons and equipment.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

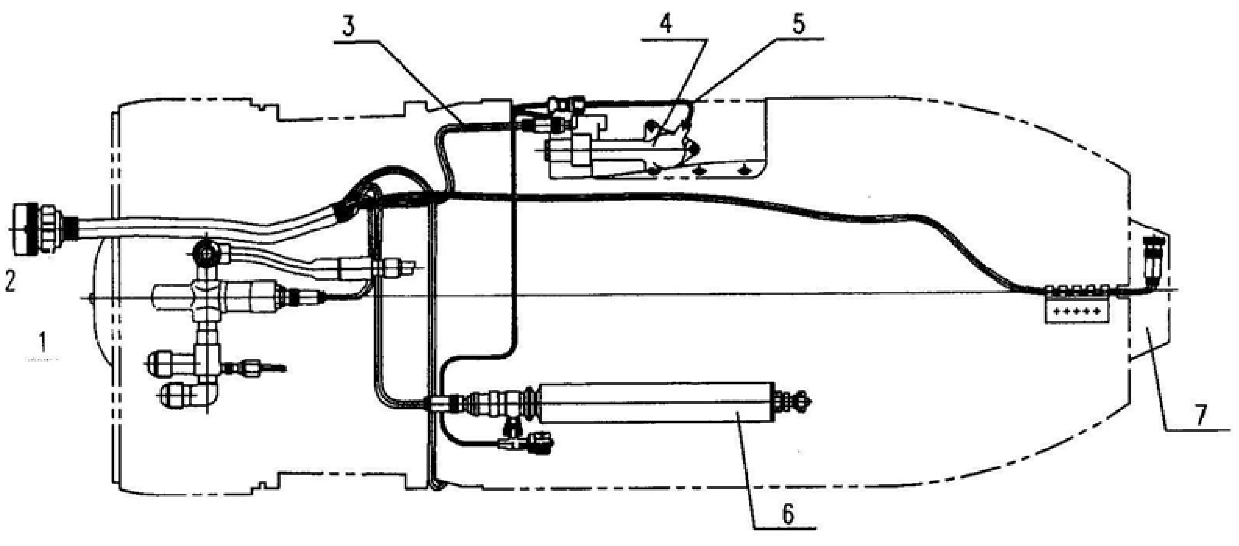

The invention relates to an engine pyrotechnic starting system, which includes an engine oil supply pipe, an oxygen bottle, a pyrotechnic igniter, and a pyrotechnic starter. The pyrotechnic igniter is installed on the combustion chamber, and the pyrotechnic starter is installed at the tail of the engine. , the fuel supply pipe of the engine, the pyrotechnic igniter, the pyrotechnic starter and the gas outlet of the oxygen cylinder are equipped with electric detonators and are all connected to the external integrated controller, and one end of the fuel supply pipe is connected to the external fuel oil The other end is connected with the nozzle of the combustion chamber of the engine, and the oxygen cylinder is connected with the pyrotechnic igniter through the oxygen supplement pipe. Valves are also arranged at the electric initiator at the inside and at the gas outlet of the oxygen cylinder. The invention has the characteristics of simple structure, high starting success rate and reduced engine weight, can directly ignite the auxiliary fuel oil of the engine, and at the same time use an oxygen bottle to ignite and replenish oxygen, thereby shortening the ignition time of the engine.

Description

Engine pyrotechnics starting system technical field The invention relates to a starting system, in particular to an engine pyrotechnic product starting system. Background technique At present, the vast majority of aero-engines use starter motors to rotate, fuel solenoid valves are turned on to supply fuel, and electric ignition coils are ignited. The starter motor is used to turn the engine turbine, the ground start can use the power vehicle, and the air start can only use the battery. The ignition system uses a coil and an ignition nozzle. In most cases, the starting fuel needs to be ignited first, and then the main fuel is ignited by the resulting small torch. This ignition form is relatively low reliability for bomb engines. For small turbofan engines, the above-mentioned auxiliary engines are large in size, low in efficiency, long in engine start-up time, and relatively high in cost, which cannot meet the requirements of rapid response and reliable maneuverability of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F02C7/272

Inventor 王学斌石光张玉宝杨宇斌王智宇

Owner HARBIN DONGAN ENGINE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com