Downhole directional hydraulic jetting tool ground control method

A surface control and hydraulic injection technology, which is applied in directional drilling, automatic drilling control system, liquid/gas jet drilling, etc., can solve the problem of lack of accurate downhole orientation ability, inability to realize downhole directional injection, and injection tools cannot be rotated in place and other problems, to achieve the effect of solving limited reservoir transformation, large torque, and avoiding misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for controlling a downhole directional hydraulic injection tool on the ground, comprising the steps of:

[0040] a. When the downhole directional injection tool reaches the deep position of the injection well, start the downhole directional injection tool through ground control;

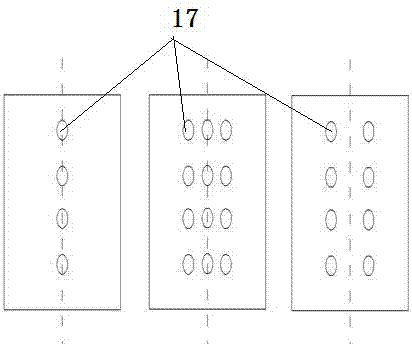

[0041] b. After the downhole directional injection tool is started, identify the circumferential orientation of the injection hole 17 along the wellbore. After determining the initial circumferential orientation of the injection hole 17 in the downhole, compare and analyze it with the set final injection orientation, and obtain that the spray gun 16 needs to rotate direction and angle of

[0042] c. Control the spray gun 16 to rotate according to the required direction and angle, and adjust the orientation of the injection hole 17 along the wellbore circumference to the specified orientation;

[0043]d. When the injection hole 17 on the spray gun 16 is adjusted in place, start direct...

Embodiment 2

[0061] This embodiment further illustrates the present invention in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

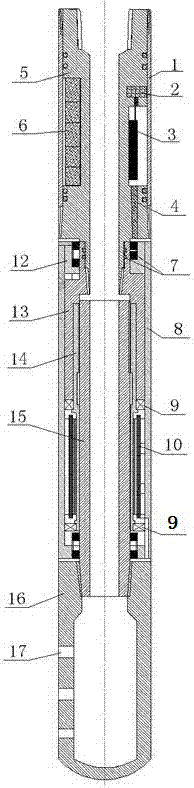

[0062] As shown in the figure, the present invention is mainly divided into two parts: surface control and downhole execution. The ground control part mainly sends start commands to the downhole to ensure that the tool starts to work when needed, which can save battery power to the greatest extent; the downhole part is the downhole directional injection tool, which mainly realizes automatic positioning of spray gun 16 nozzles and along the wellbore circumference. Adjustment.

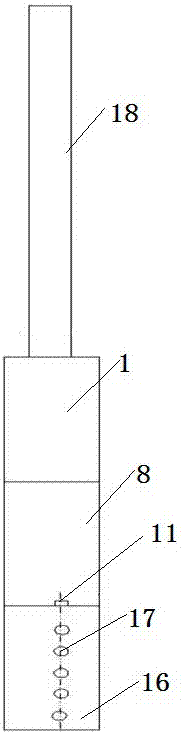

[0063] figure 1 It is a schematic diagram of the downhole tool string of the directional hydrojet tool used for fracturing and acidizing stimulation. The downhole directional injection tool is composed of three parts: a control device,...

Embodiment 3

[0071] After determining the circumferential orientation of the wellbore that the reservoir needs to inject, input the injection orientation data to the downhole directional injection tool on the ground in advance (that is, the injection hole ultimately needs to correspond to the circumferential injection orientation of the wellbore), and set the direction that needs to be injected downhole . When construction is required, the downhole directional injection tool is connected with oil pipe or coiled tubing 18, and sent downhole. When the downhole directional injection tool reaches the deep position of the injection well, the downhole directional injection tool is started by sending a ground control command by throwing an RFID communication ball into the tubing. When the RFID communication ball passes through the downhole directional injection tool with the downhole fluid, the downhole directional injection tool The built-in RFID reader receives the control signal and starts the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com