Industrial robot zero-position self-calibration method and device

An industrial robot and robot technology, which is applied to measuring devices, optical devices, instruments, etc., can solve the problems of complicated installation and operation, low positioning accuracy, expensive equipment, etc., and achieve the effect of high degree of automation, high precision and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

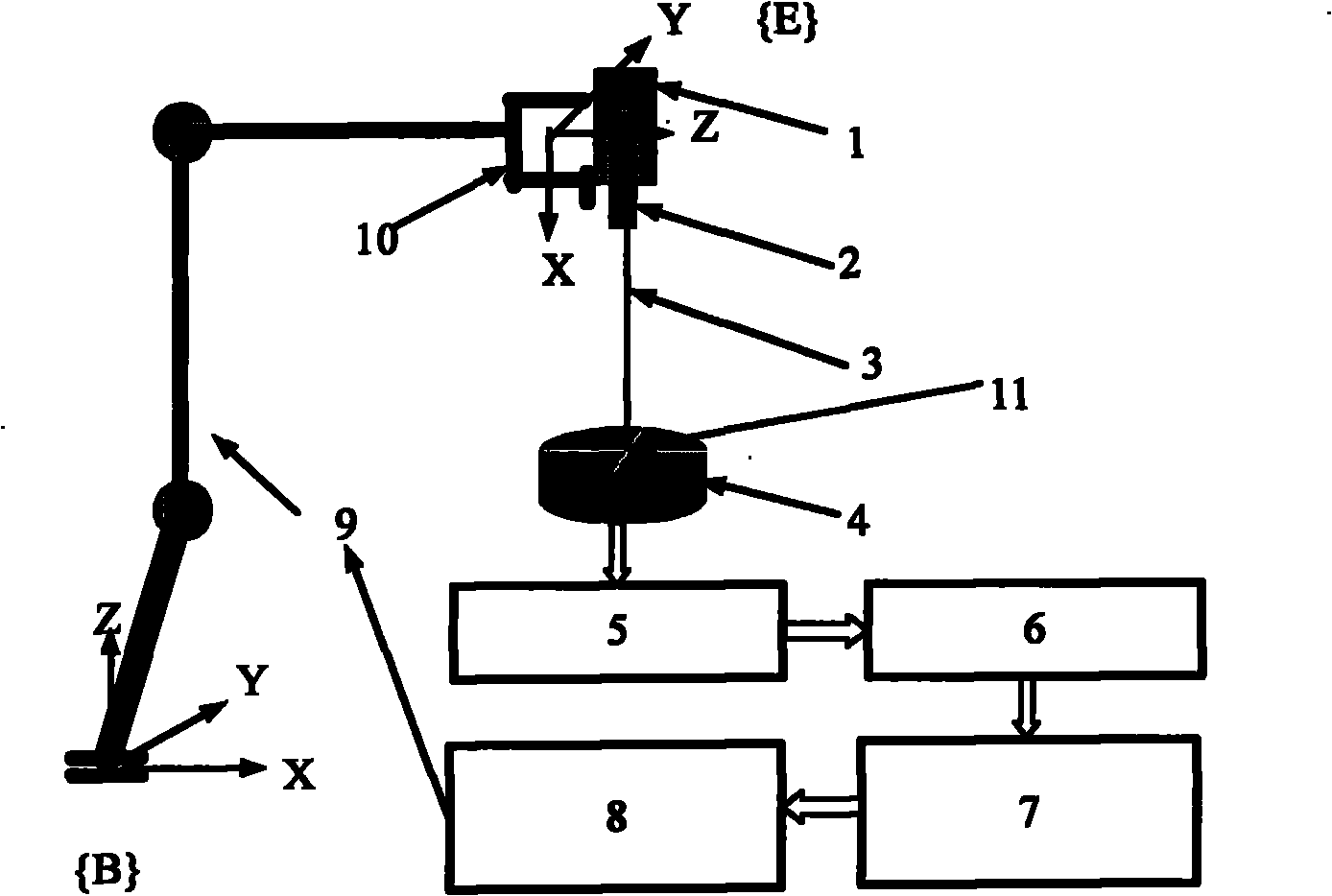

[0035] Using the device of the present invention to carry out the calibration test on the industrial robot IRB1600, the specific implementation steps are as follows:

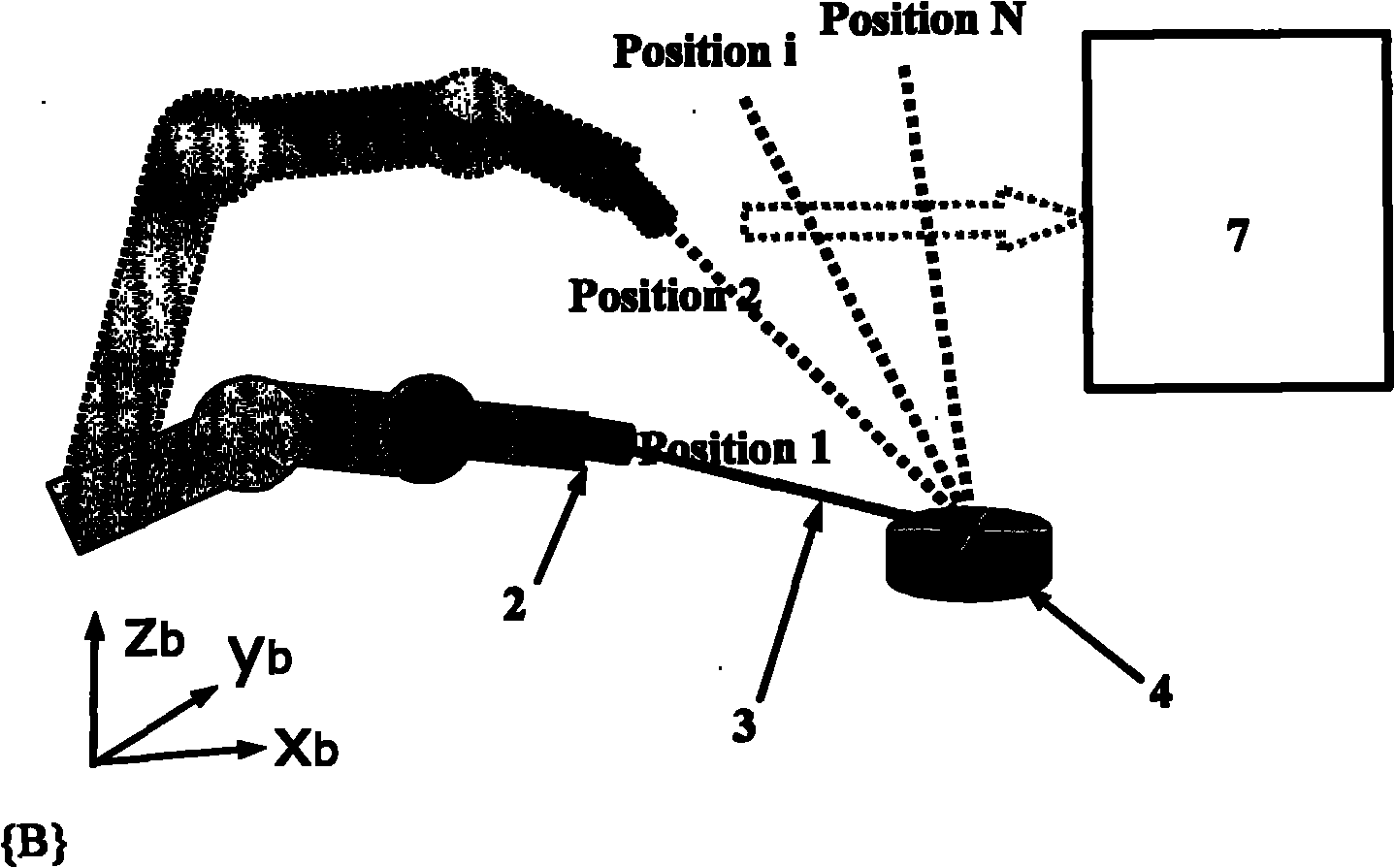

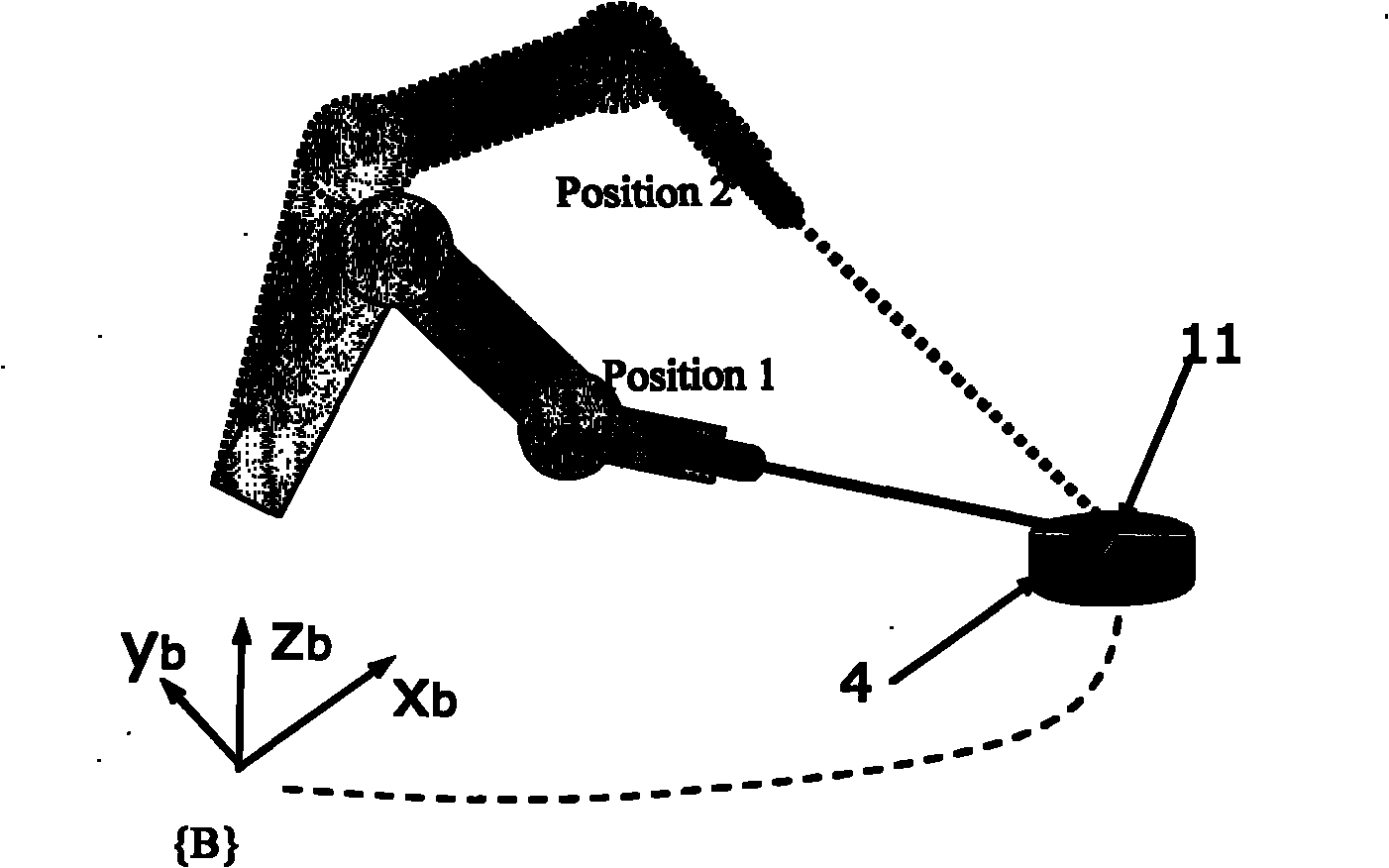

[0036] a) Arbitrarily place the PSD device in the robot workspace, and establish space virtual point constraints. Note that the spatial location of this constraint point is unknown. The position sensitive device PSD 4 adopts a segmented high-precision photoelectric device with a resolution of 0.1um and an effective surface diameter of 10mm, which can detect the two-dimensional position of the laser beam spot on the PSD surface. The PSD output signal is given the two-dimensional position coordinates of the laser spot on the PSD surface by the signal processing circuit 5, which is used as a feedback signal to precisely control the position of the robot, that is, the center point of the PSD surface is used as the robot positioning target position.

[0037] b) Precise robotic positioning based on laser and PSD. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com