Industrial robot online zero position calibration device based on all-dimensional point constraint and method

An industrial robot and zero-position calibration technology, which is used in measuring devices, optical devices, instruments, etc., can solve the problems of robot end position deviation, large error, and low positioning accuracy of industrial robots, and achieve the effect of reducing errors and high accuracy.

Active Publication Date: 2014-11-05

NANJING UNIV OF SCI & TECH

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Small changes in the zero position of the robot cause a large deviation in the position of the end of the robot due to the magnification of the rod length, etc.

It is generally believed that 90% of the problems that lead to low positioning accuracy of industrial robots come from the zero position of robots (W. S. Newman and D.W.Osborn, "A new method for kinematic parameter calibration via laser line," in Proc. IEEE Int. Conf. Robot. Autom., 1993, vol. 2, pp. 160–165)

Yong Liu and Ning Xi proposed a calibration method based on single-point constraints (Yong Liu, Ning Xi, and Jianguo Zhao, "Development and Sensitivity Analysis of a Portable Calibration System for Joint Offset of Industrial Robot," IEEE / RSJ International Conference on intelligent Robots and Systems on louis ,11-15 October 2009), Liu Yong proposed an industrial robot zero calibration method and device in the invention patent (patent number: 201010267775.7) Method, this method uses the laser to emit the laser beam PSD to receive the laser beam, because the PSD is fixed, so when the cylindrical laser beam is obliquely projected onto the center point of the PSD, a large error will occur

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0046] Table 1 Example IRB1600 robot zero calibration results (unit: degree)

[0047] Calibration parameters actual value initial value Calibration result average error

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

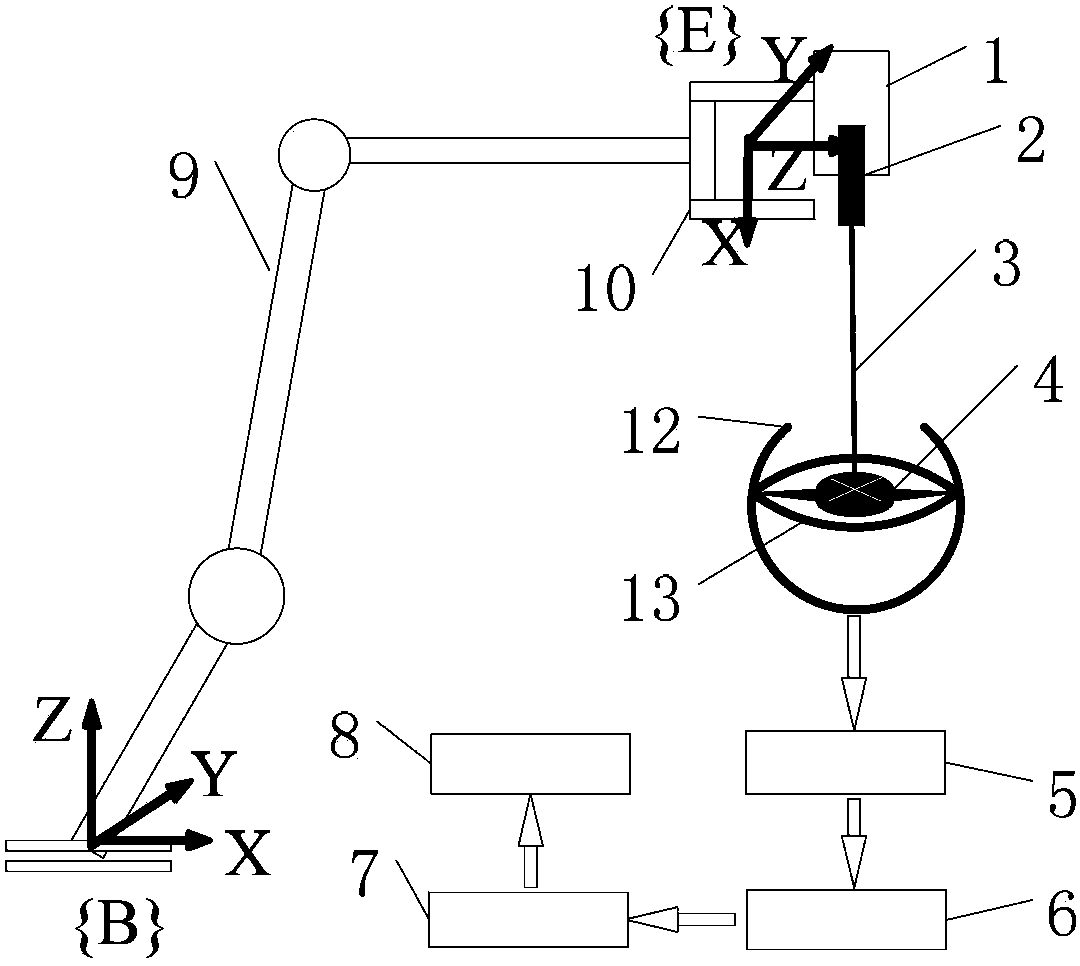

The invention discloses an industrial robot online zero position calibration device based on all-dimensional point constraint and a method of the device. The device comprises a laser point light source, and an all-dimensional receiving device, wherein a laser serves as the laser point light source; the all-dimensional receiving device consists of a PSD (position sensitive detector), an inner ring stand, an outer ring stand, a signal processing circuit, a data acquisition card, an industrial control computer, and an industrial robot controller; the inner ring stand and the outer ring stand are connected together through a globe joint to form a ring stand; the laser is rigidly fixed on the tail end of an industrial robot body through a connection device; two link rods have a globe joint at one ends; the globe joints are connected with the inner ring stand; the other ends of the two link rods are rigidly connected with the PSD; and the PSD is located at the center of the ring stand. The industrial robot online zero position calibration device provided by the invention not only overcomes the disadvantages caused by fixing the PSD stably in the prior art, but also reduces the error generated by projecting the round laser beam onto the center point of the PSD obliquely.

Description

A technical field [0001] The invention belongs to the calibration technology of industrial robots, in particular to a self-calibration method and device for the joint zero position of an industrial robot. Two background technology [0002] With the expansion of the application range of industrial robots and the need for complex tasks, the positioning accuracy of industrial robots is becoming more and more important. At present, industrial robots have high repeatability (0.1mm or higher), but (absolute) positioning accuracy is very low (up to 1cm or worse). The problem of positioning accuracy has seriously restricted the application capabilities and scope of industrial robots. Although there are many factors that lead to the low positioning accuracy of the robot, such as gear error, thermal expansion, and mechanical deformation of the robot rod, the most important factor comes from the parameter error of the robot kinematics model. Robot calibration technology is the most ef...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01B11/00

Inventor 刘永时定兵

Owner NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com