Online industrial robot calibration device based on spatial curved surface restraint

An industrial robot and curved surface constraint technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of robot end position deviation, large error, and low positioning accuracy of industrial robots, so as to achieve easy development, expand calibration space, reduce The effect of small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

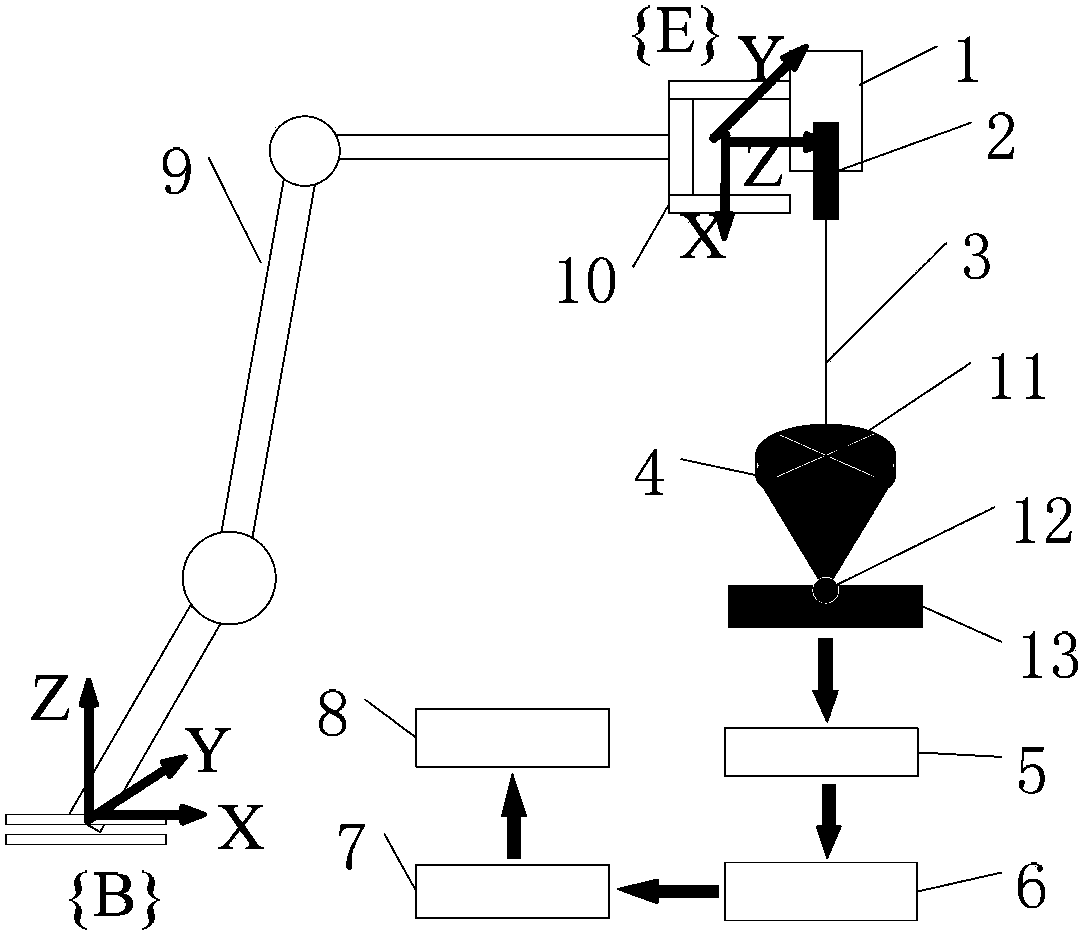

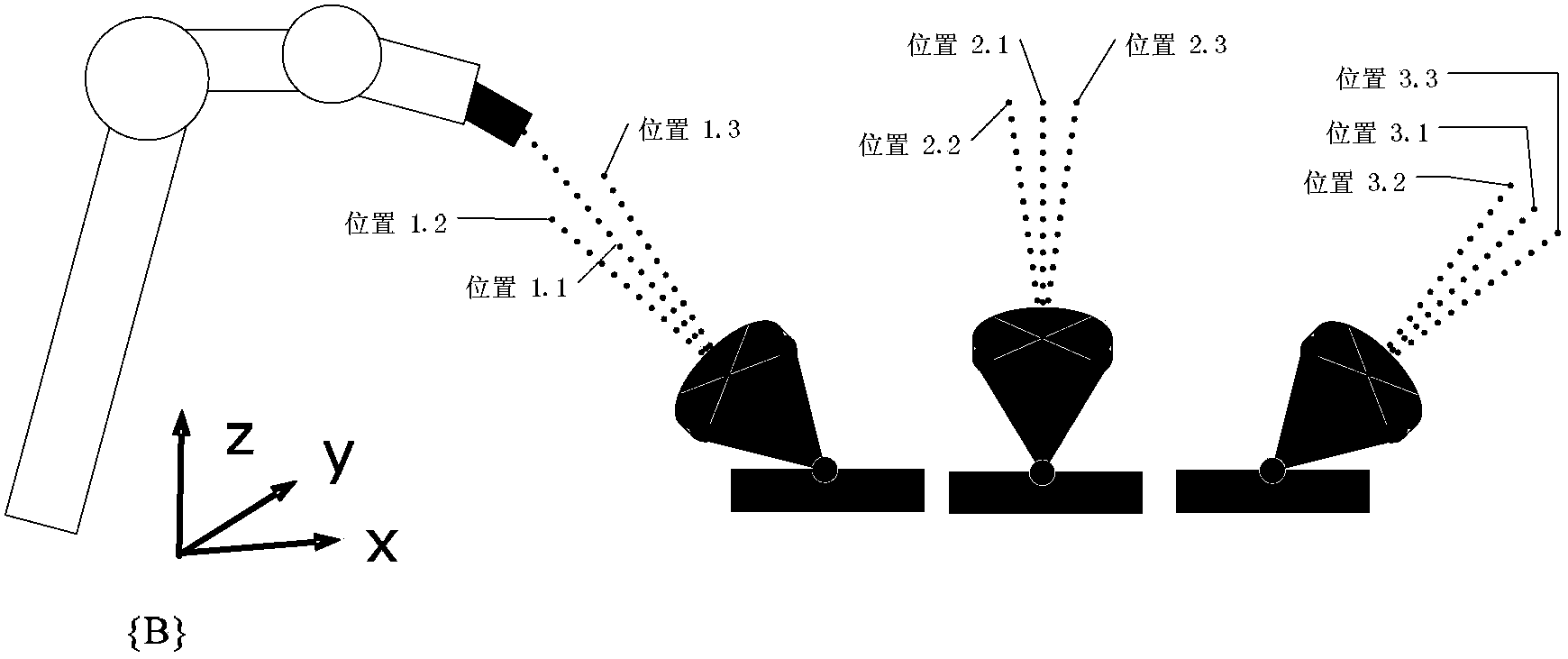

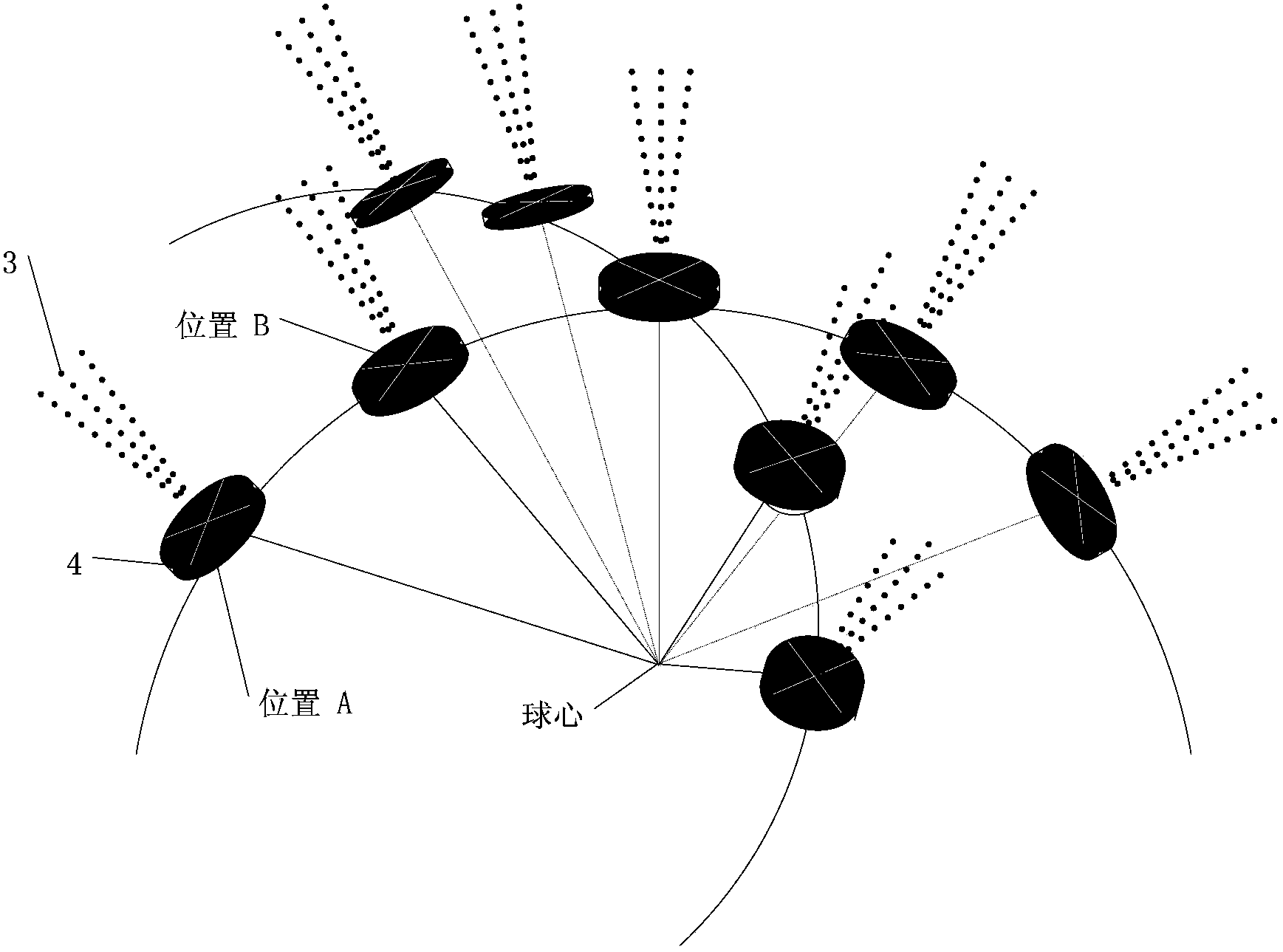

[0019] to combine figure 1, the online calibration device for industrial robots based on spatial surface constraints in the present invention includes a receiving device for a point source laser 2 and a laser beam 3, and the receiving device is composed of a position sensitive device (PSD for short) 4, a ball joint 12, a base 13, and a signal processing circuit 5. Data acquisition card 6, industrial control computer 7, and industrial robot controller 8. The laser 2 is rigidly fixed to the end 10 of the robot through the connecting device 1. During the calibration process, the relationship between the laser 2 and the end remains unchanged. The receiving device is placed In the working space of the industrial robot body 9, the PSD4 is fixedly connected to the ball joint 12 through a rigid connecting rod, the data collector card 6 is connected to the PSD4 through the signal processing circuit 5, and the data collector card 6 can be connected to the industrial control computer thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com