Welding protection line for reinforcing mesh

A production line and steel mesh technology, applied in the field of metal building materials welding and bending processing equipment, can solve problems such as low efficiency, poor compatibility, and poor product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

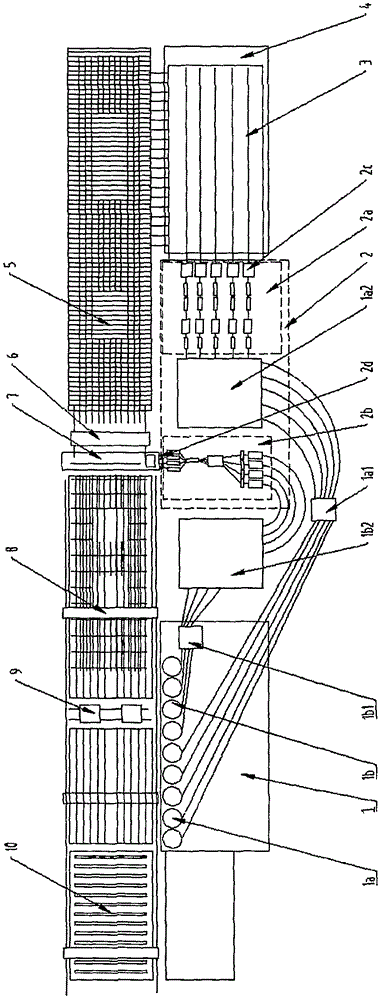

[0125] Example 1 wire feeding

[0126] 1a. Longitudinal wire feeding

[0127] 1.1a The longitudinal rib is wound down from the pay-off bracket 11;

[0128] 1.2a The longitudinal rib passes through the longitudinal rib pay-off device 1a to ensure the correct conveying direction and the correct conveying height of the longitudinal rib;

[0129] 1.3a The longitudinal rib enters the longitudinal rib wire storage rack, adjusts the direction and height of the longitudinal rib to ensure that it can be straightened smoothly;

[0130] 1.4a The longitudinal bars enter the longitudinal bar rotary straightening machine 2a2, the longitudinal bar vertical straightening machine 2a4, and the longitudinal bar vertical straightening tractor 2a3 successively through the longitudinal bar rotary straightening tractor 2a1 for straightening;

[0131] During the straightening process of the longitudinal rib rotary straightening machine 2a2, the longitudinal rib passes through the rotating straighte...

Embodiment 2

[0139] Embodiment 2 shearing (the longitudinal rib and the transverse rib all complete the shearing step by the shearing machine 2c, and the two shearing steps are the same)

[0140] 2a Longitudinal reinforcement shearing

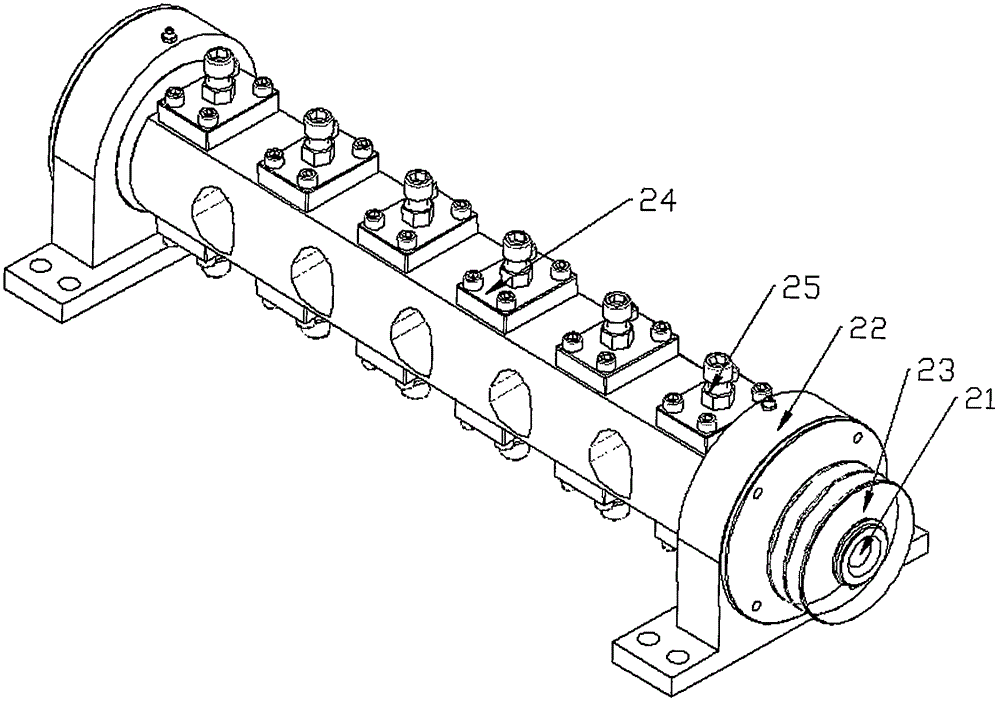

[0141] 2a.1 The longitudinal rib passes between the shearing conveying traction wheel 2c2 and the shearing conveying pressing wheel 2c3. surplus contact, so it is necessary to adjust the height of the shearing and conveying pressing wheel 2c3 through the shearing and conveying pressing wheel cylinder 2c4;

[0142] 2a.2 With the rotation of the shearing and conveying traction wheel 2c2 and the shearing and conveying pressing wheel 2c3, the longitudinal tendons continue to move into the cutter 2c9;

[0143] The shear cylinder 2c8 described in 2a.3 is pressed down to cut off the longitudinal ribs;

[0144] 2a.4 The shear push cylinder 2c6 pushes the longitudinal ribs into the hub;

[0145] 2b cross bar shearing

[0146] 2b.1 The transverse rib passes betwe...

Embodiment 3

[0150] Embodiment 3 Longitudinal reinforcement assembly line

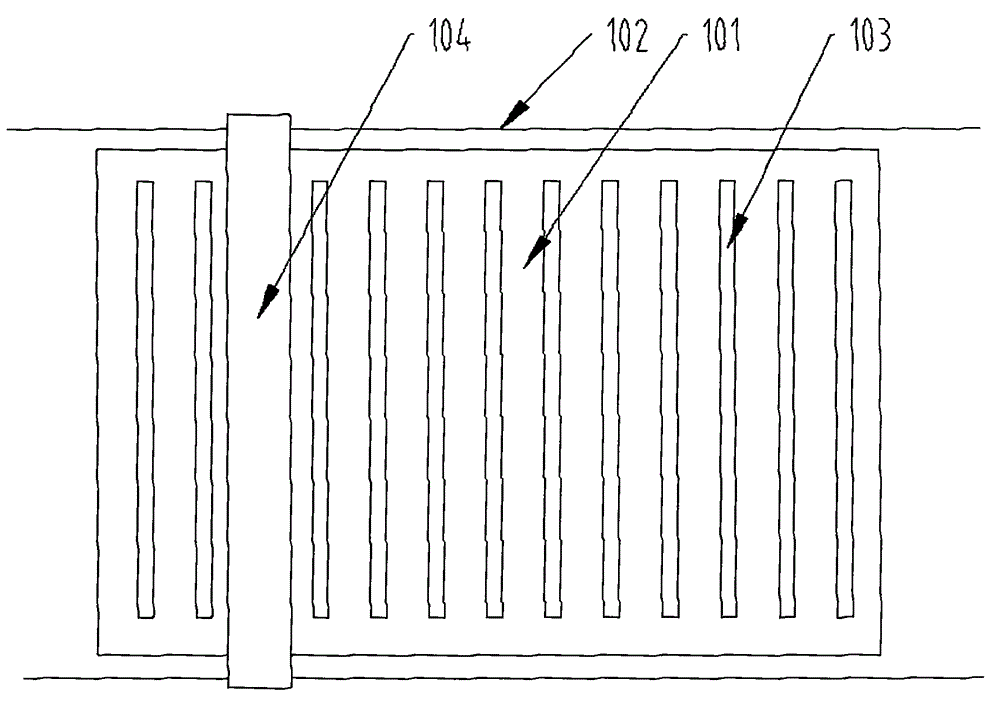

[0151] 3.1 The longitudinal rib passes between the fixed clamp bar 33 and the opening and closing clamp bar 34;

[0152] 3.2 The clamping rod cylinder 38 is started, and the fixed clamping rod 33 and the opening and closing clamping rod 34 are opened through transmission components such as the clamping rod crowbar 36 and the clamping rod arm 37;

[0153] 3.3 The longitudinal reinforcement automatically falls to the longitudinal reinforcement matching machine 4;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com