Method for producing ultra-fine basalt continuous filament

A production method and continuous fiber technology are applied in the production field of ultra-fine basalt continuous fibers, which can solve the problems of uneven electrode distribution, unstable operation, inconvenient basalt continuous fibers, etc., and achieve reasonable furnace body design, optimized electrode layout, wire drawing. Process stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the method for producing the ultrafine basalt continuous fiber according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

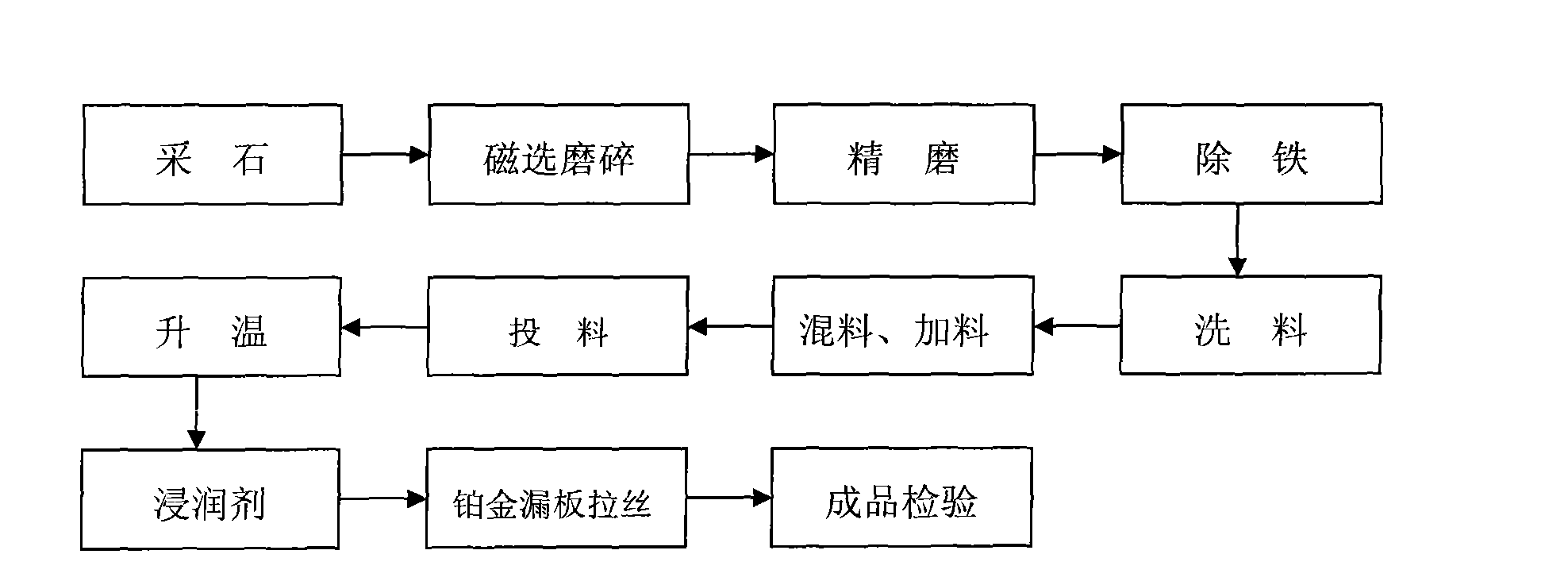

[0058] See figure 1 As shown, the production method of ultrafine basalt continuous fiber according to the preferred embodiment of the present invention mainly includes the following steps:

[0059] 1. Beneficiation

[0060] The first is to crush the ore mined from the mine and process it into gravel with a diameter of 5mm.

[0061] 2. Ore crushing and sieving.

[0062] Grind the ore into small pieces with a diameter of less than 1mm, wash it, and continue to grind it into a powder of about 30 mesh.

[0063] 3. Iron removal of mixed raw materials.

[0064] In the process of removing iron, a chemical iron removal method is used. After acid le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com