Double-refraction microstructure optical fiber and its mfg. method

A micro-structured optical fiber and birefringence technology, applied in the direction of light guides, optics, optical components, etc., can solve problems such as limitations and inability to propagate light waves, and achieve the effects of low cost, good polarization temperature stability, and high birefringence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The structure and manufacturing method of the birefringent microstructure optical fiber of the present invention will be explained in detail below in conjunction with the accompanying drawings.

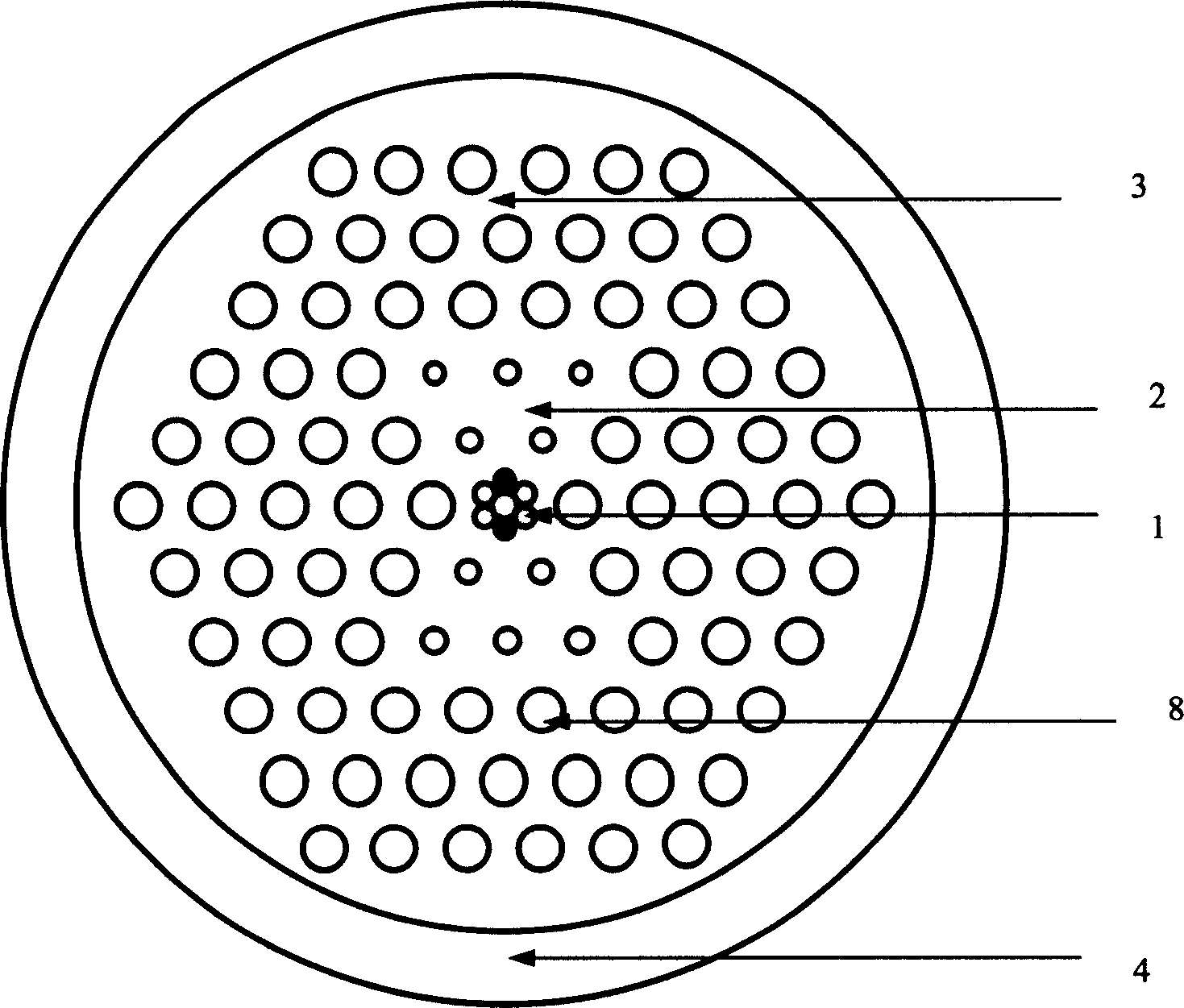

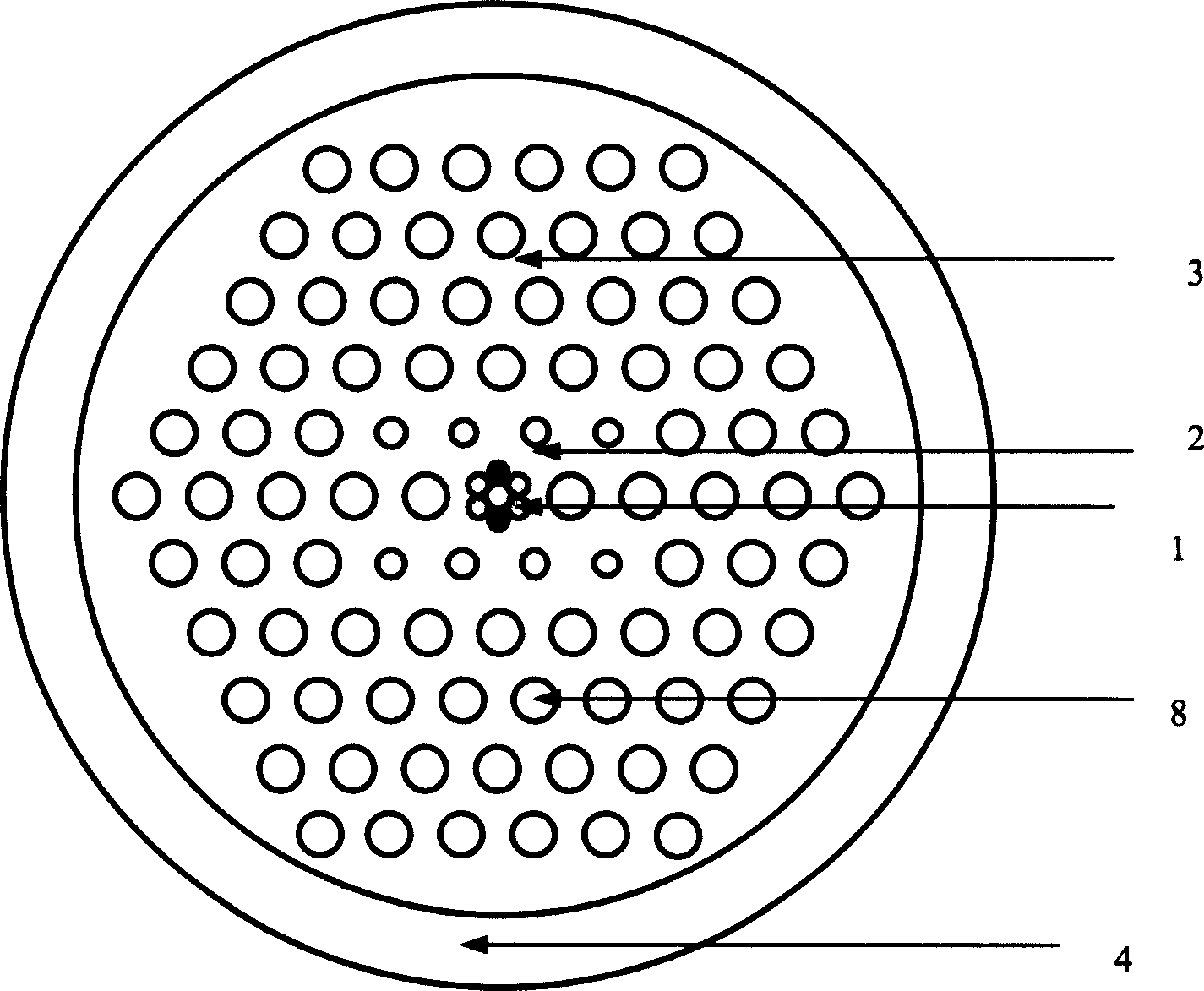

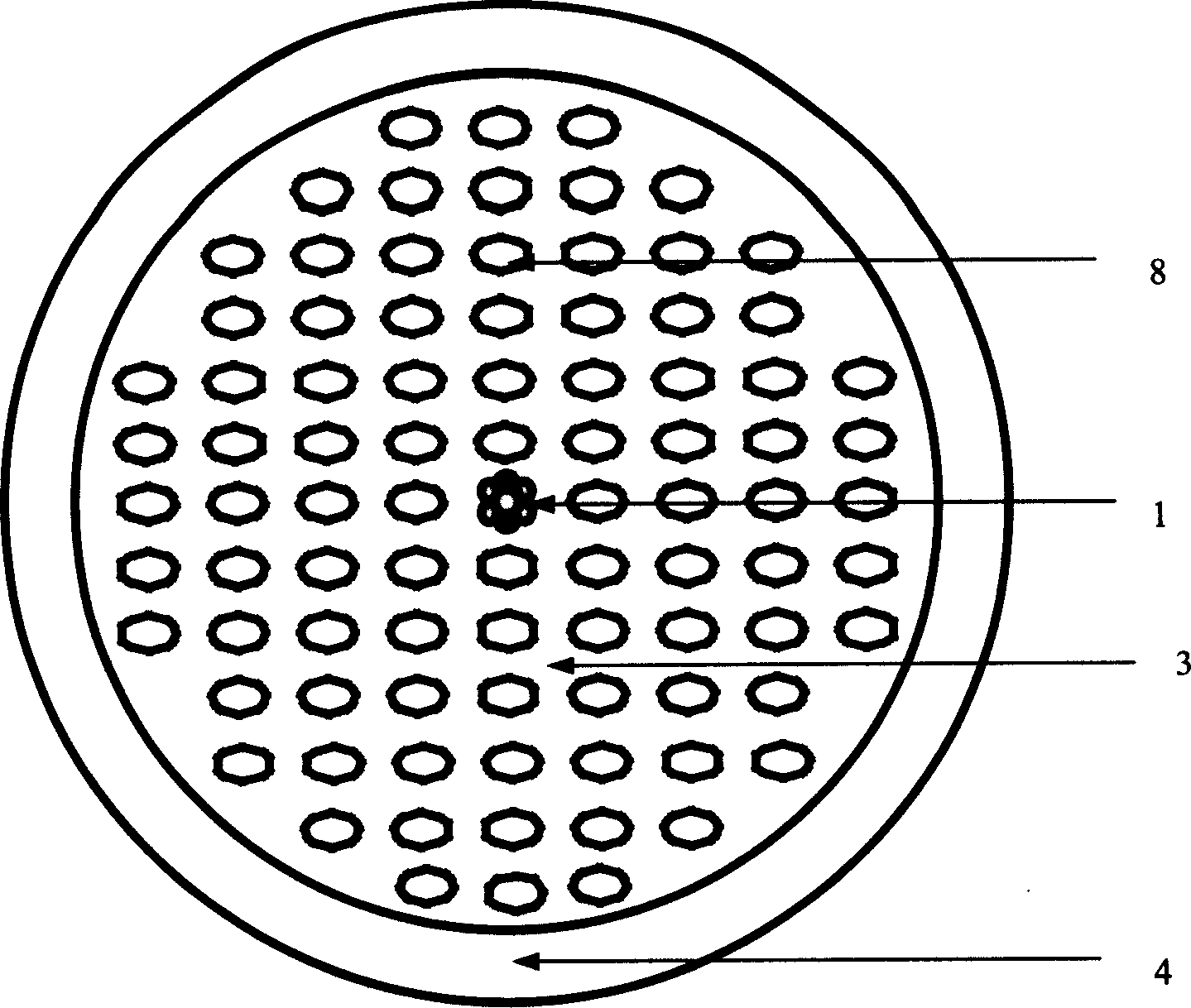

[0041] figure 1 It is a cross-sectional schematic diagram of an optical fiber with a "figure-eight" birefringence microstructure. The fiber is composed of an inner region 1 surrounding the core, and microholes with smaller diameters form a cladding region 2 of a "figure-eight" structure. The circle The cladding area 3 is composed of a hexagonal array of micro-holes arranged in a hexagonal structure, and an optical fiber coating area 4 composed of an organic polymer, and the micro-holes 8 in the cladding are approximately circular. The micropore diameter in the cladding region 2 is smaller than that in the cladding region 3, and the distribution along the axial direction perpendicular to each other of the optical fibers presents a "figure-eight" distribution, so it is effective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com