A stress-focused axis-aligning Panda polarization-maintaining fiber and its axis-aligning method

A polarization-maintaining fiber and axis-type technology, which is applied in the direction of polarization-maintaining fiber and cladding fiber, can solve the problems of reducing the birefringence consistency of polarization-maintaining fiber, reducing the alignment efficiency and accuracy, and affecting the field of view on the axis, etc. Effect of small fiber outer coating diameter, improved accuracy and efficiency, and high birefringence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

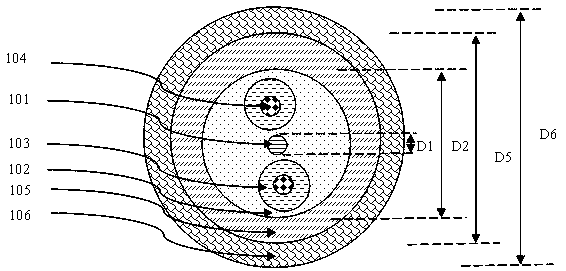

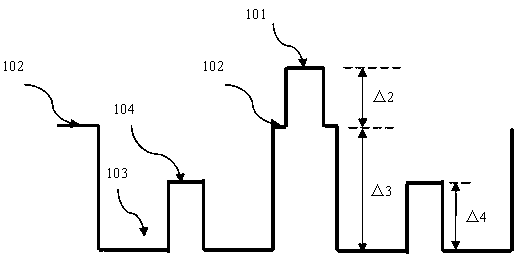

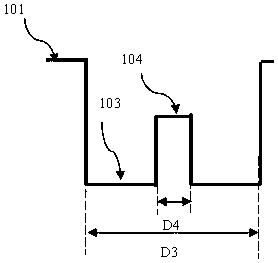

[0025] see Figure 1~3 , the present invention relates to a stress-focused axial-type panda polarization-maintaining optical fiber, the optical fiber includes a core 101 wrapped in the center of the cladding 102, and the cladding 102 is also provided with a stress zone 103, and the stress zone 103 is symmetrical Set on both sides of the fiber core 101, the center of the stress zone 103 is provided with a focusing light-transmitting circle 104, the refractive index of the above-mentioned focusing light-transmitting circle 104 is higher than that of the stress zone 103; the diameter D1∈(3 μm , 5 μm), the diameter D2∈ (58 μm, 81 μm) of the cladding layer 102, the diameter D3∈ (10 μm, 30 μm) of the stress zone 103; the inner coating layer 105 and the outer coating layer 105 and the outer coating layer 105 are also sequentially coated outside the cladding layer 102 during application. The coating layer 106, at this time, the diameter D5∈(85 μm, 115 μm) of the inner coating layer 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com