High-sensitivity pressure-sensing photonic crystal fiber and pressure sensor thereof

A photonic crystal fiber and high-sensitivity technology, which is applied in clad fiber, optical waveguide and light guide, and the measurement of the change force of the optical properties of the material when it is stressed, can solve the problem of small deformation of the pressure sensor, low pressure sensitivity, Poor bending resistance and other problems, to achieve the effects of reducing impact, improving sensing sensitivity, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

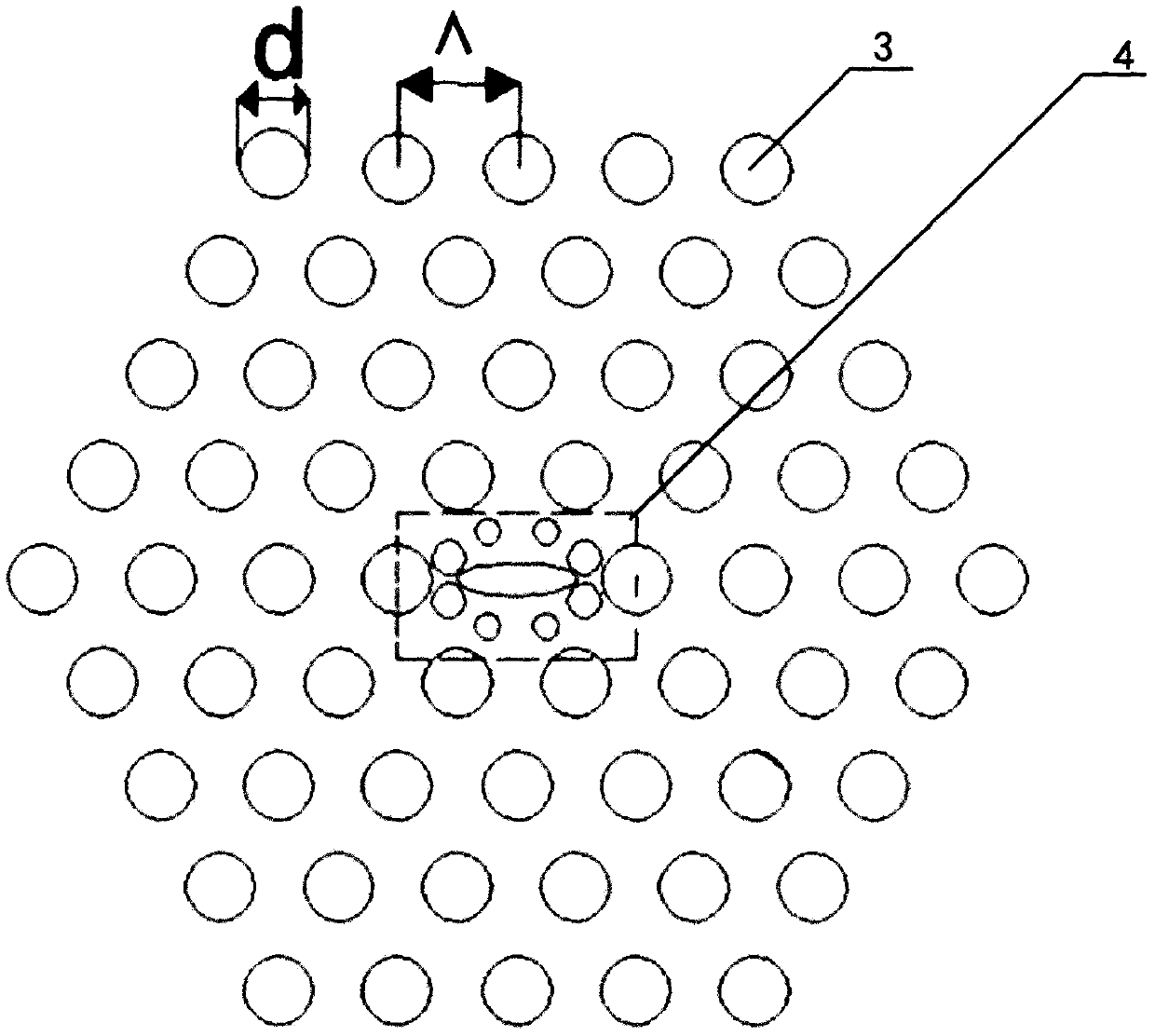

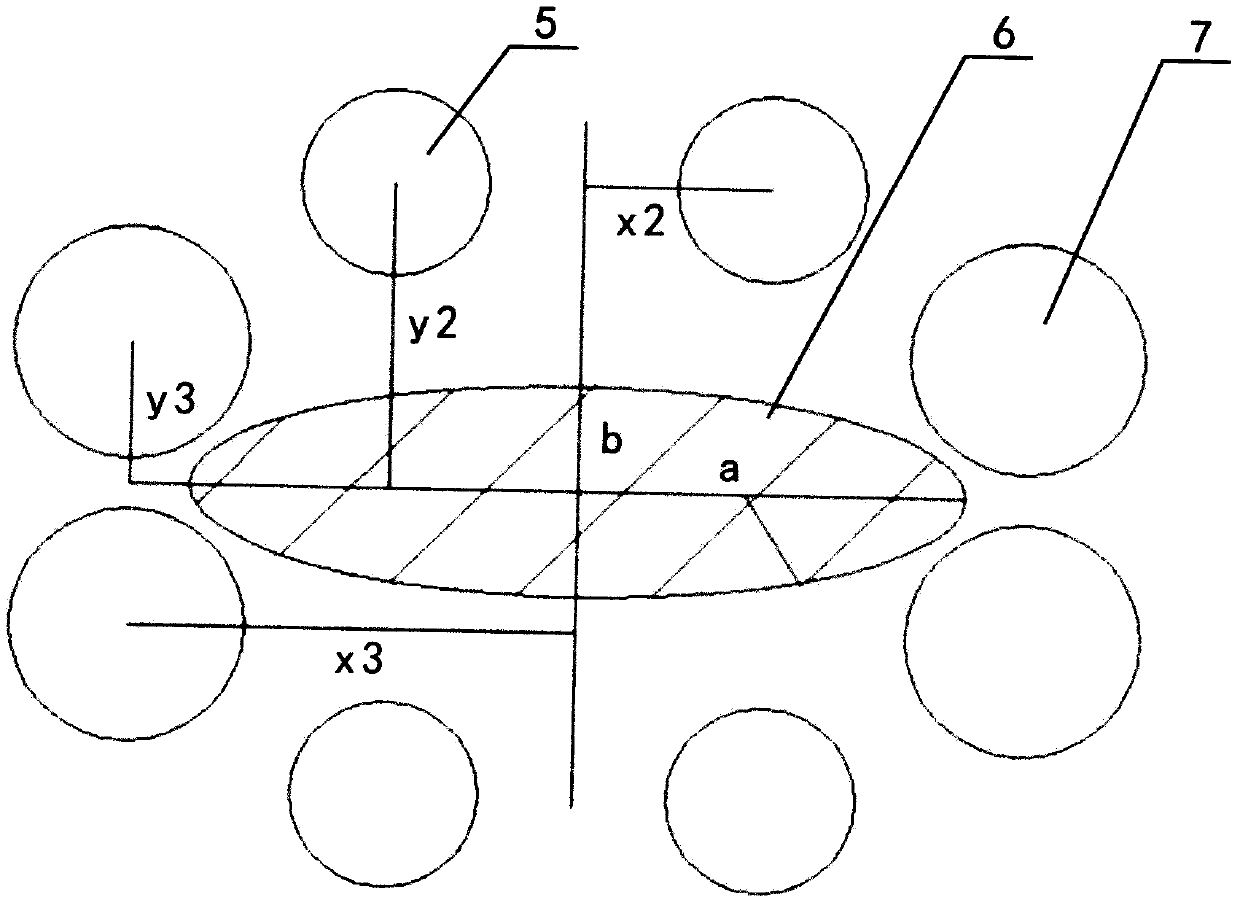

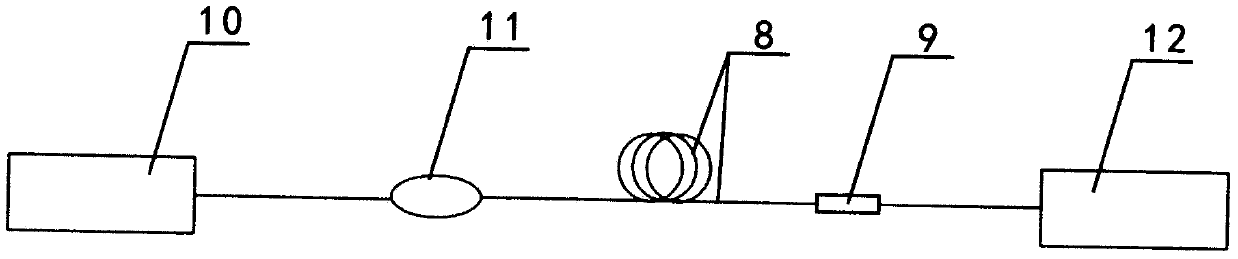

[0029] Such as Figure 1-Figure 3 As shown, the high-sensitivity pressure sensing photonic crystal fiber of the present invention comprises a strip-shaped quartz body 1, and the central position in the quartz body 1 is provided with an axial strip-shaped and radially elliptical elliptical through hole (in the figure unmarked), the elliptical through hole is filled with polycarbonate to form an axially strip-shaped and radially elliptical elliptical core 6, and two ends of the long axis of the elliptical core 6 are respectively provided with Axial strip-shaped long-axis through holes 7, two axial strip-shaped short-axis through-holes 5, four long-axis through-holes 7 and four short-axis The outer circumference of the area surrounded by the through hole 5 is provided with a plurality of evenly distributed and axial strip-shaped small through holes 3, and the plurality of sma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| refraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com