Fiber pressure-retaining drawing device under pressurized steam

A technology of drafting device and water vapor, which is applied in the field of carbon fiber raw silk textile equipment, can solve the problems of inability to achieve high draft and pressure can not meet the process requirements, etc., to improve orientation and strength, improve plasticity, and good heat conduction Through the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

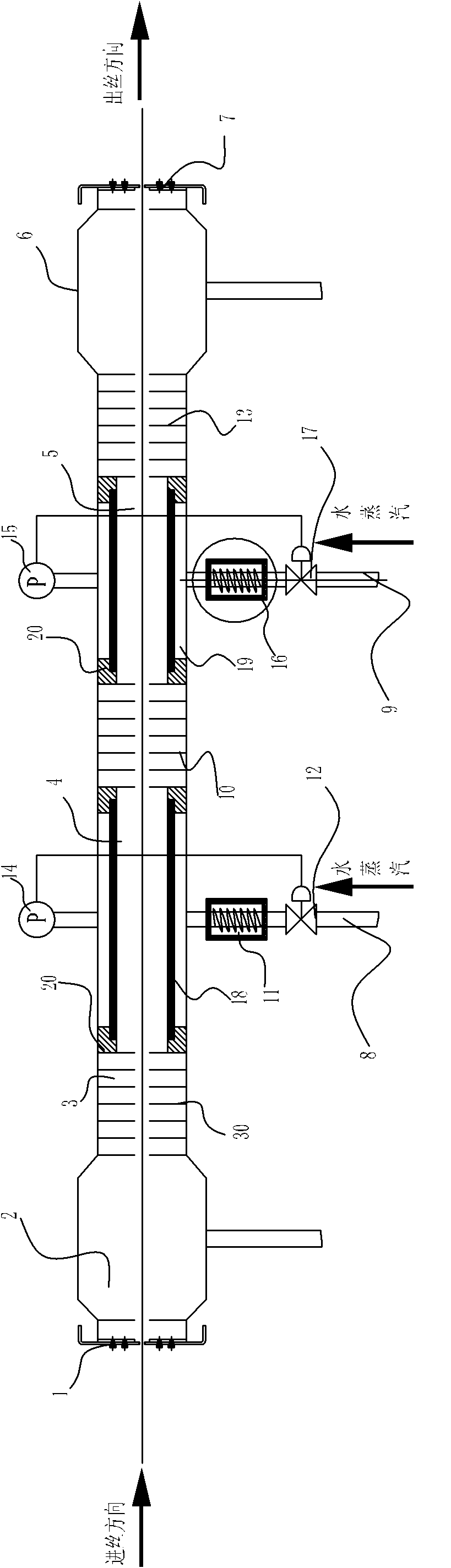

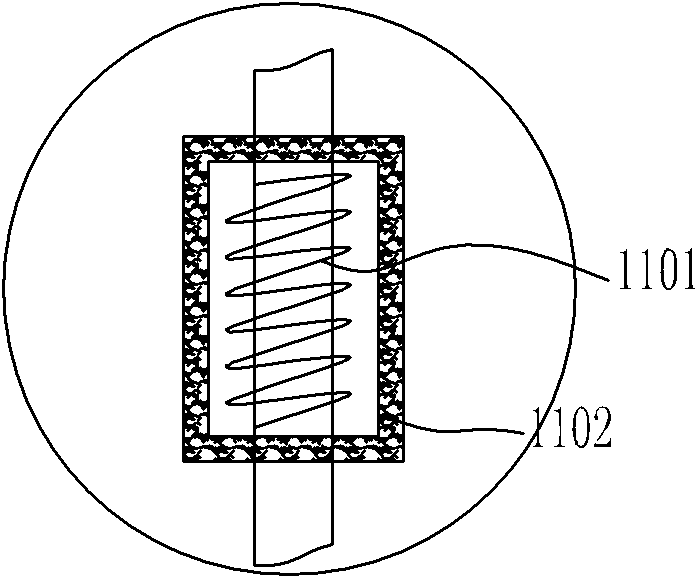

[0028] A pressure-holding drawing device for pressurized water vapor of fibers, which includes a drawing chamber and a silk-inlet steam-water collection device and a silk-out steam-water collection device arranged at both ends of the drawing chamber. The inlet steam seal part, the preheating drawing chamber, the middle steam seal part, the heating drawing chamber and the yarn outlet steam seal part are arranged in sequence. Preheating water steam pipe, the heating drawing chamber is provided with a heating water vapor pipe for supplying water vapor to the heating drawing chamber, the preheating drawing chamber is provided with a porous material, between the porous material and the preheating drawing chamber In order to preheat the hot water steam chamber, the porous material in the preheating drawing chamber is fixed by a support body, such as figure 1 As shown, the porous material is arranged in the heating and drawing chamber, and the porous material and the porous material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com