Alkali-free glass and manufacturing technique thereof

A technology of alkali-free glass and production process, applied in the field of inorganic non-metallic materials, can solve the problems of secondary pollution of solid waste, waste gas pollutants, increase of production cost, etc., and achieve the effect of sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

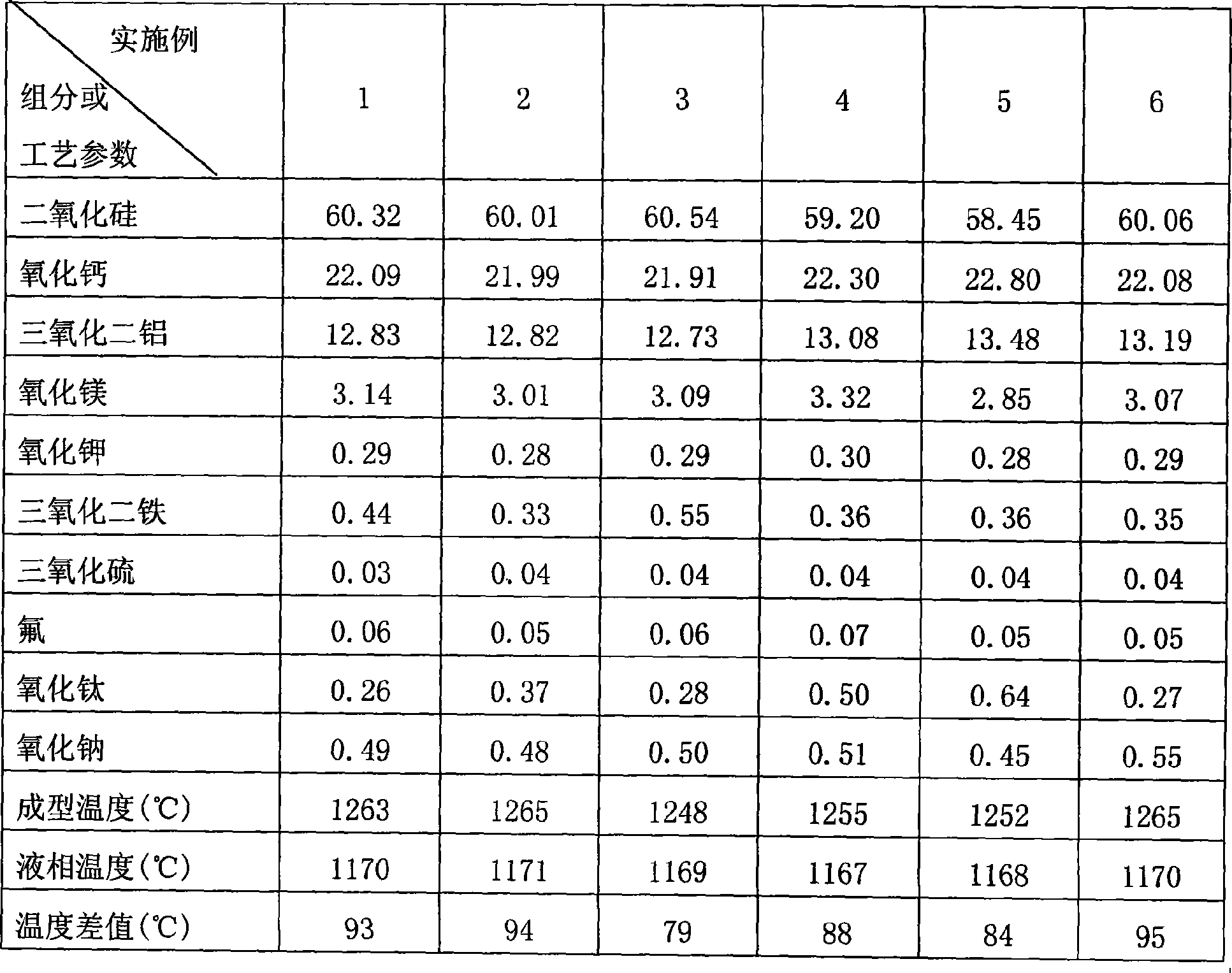

Examples

Embodiment Construction

[0009] The present invention is specifically described below through examples, but the content of the present invention is not subject to any restriction of the following examples.

[0010] The raw materials for the production of alkali-free glass usually use quartz sand, calcined limestone, pyrophyllite, and calcined dolomite. The calcined limestone can be replaced by ordinary limestone or a mixture of the two, pyrophyllite can be replaced by kaolin or a mixture of the two, and calcined dolomite can be replaced by lightly calcined dolomite. Stone or ordinary dolomite is used instead or mixed. Generally speaking, the processing procedure of the embodiment of the present invention is as follows: each component of the embodiment of the present invention can be obtained from suitable batch material or raw material (for example: the silicon dioxide in the quartz sand, the calcium oxide in the limestone, the calcium oxide in the dolomite magnesium oxide) and may contain traces of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com