High loft low density nonwoven webs of crimped filaments and methods of making same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

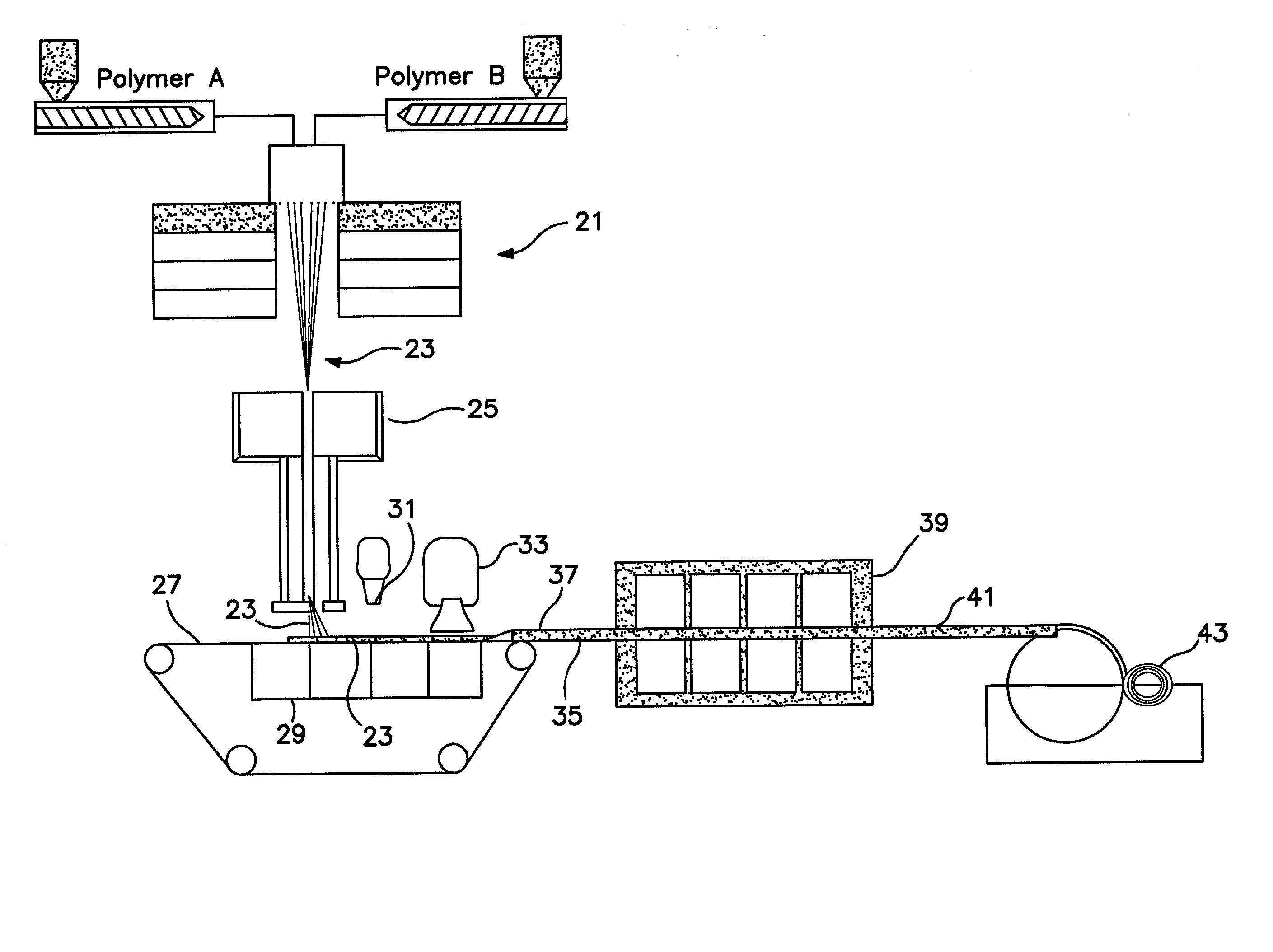

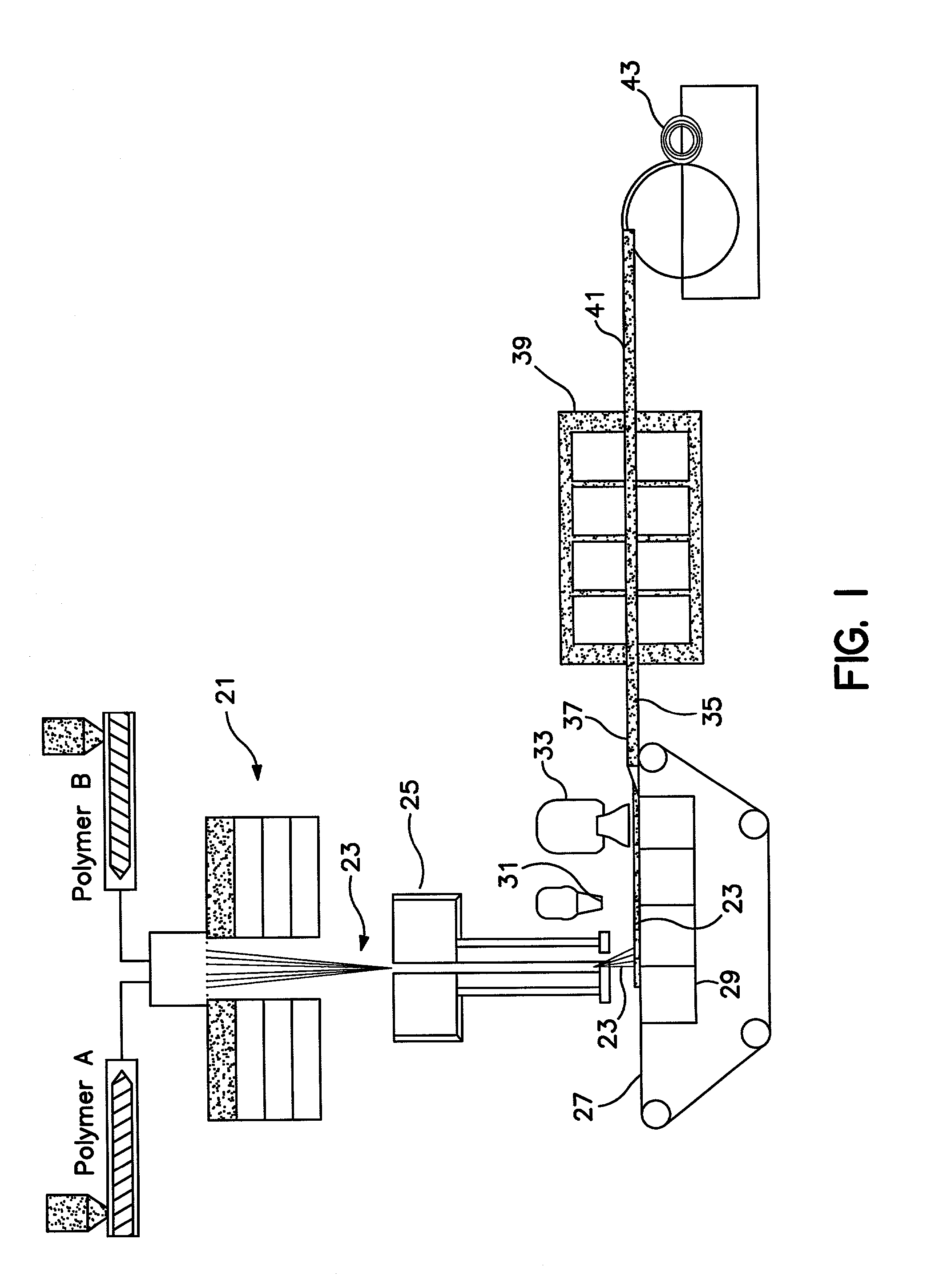

[0027] FIG. 1 is a schematic diagram illustrating methods and apparatus of this invention for producing high loft, low density materials by producing crimpable bicomponent side by side substantially continuous fibers and causing them to crimp in an unrestrained environment.

[0028] As shown in FIG. 1, two polymers A and B are spunbond with known thermoplastic fiber spinning apparatus 21 to form bicomponent side by side, or A / B, morphology fibers 23. The fibers 23 are then traversed through a fiber draw unit (FDU) 25. According to one embodiment of the present invention, unlike the standard practice in the art, the FDU is not heated, but is left at ambient temperature. The fibers 23 are left in a substantially continuous state and are deposited on a moving forming wire 27. Deposition of the fibers is aided by an under-wire vacuum supplied by a negative air pressure unit, or below wire exhaust, 29.

[0029] The fibers 23 are then heated by traversal under one of a hot air knife (HAK) 31 or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com