Fiber manufacturing method and fiber drawing furnace

A manufacturing method and technology of a wire drawing furnace, which can be applied to manufacturing tools, glass manufacturing equipment, etc., can solve the problem of not specifying the type of gas, and achieve the effect of reducing pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

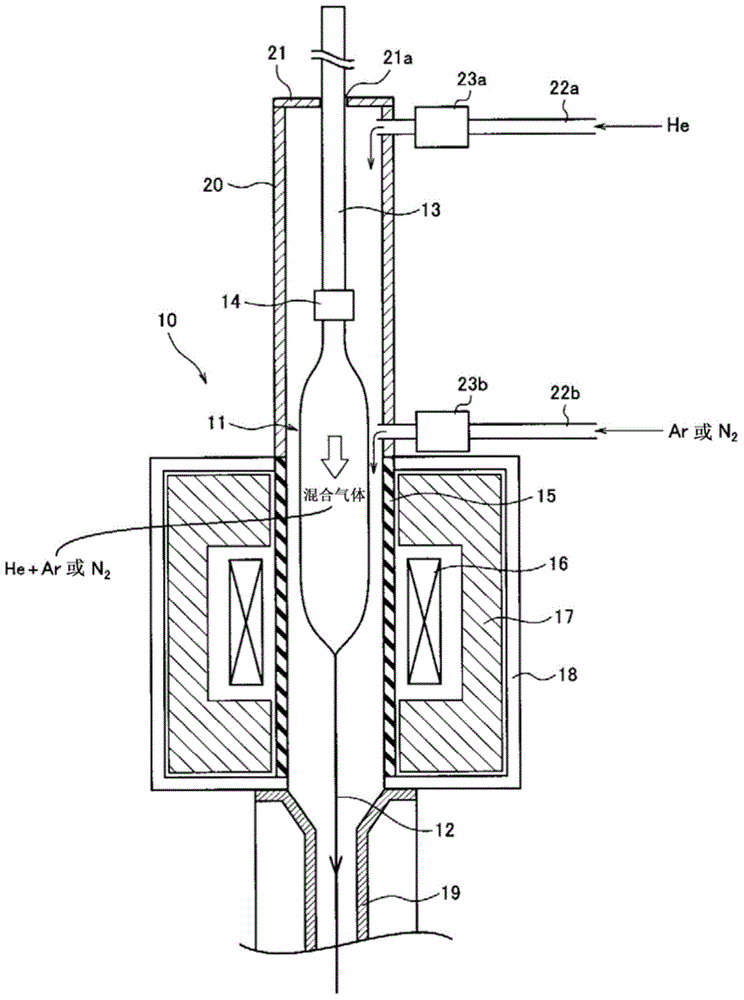

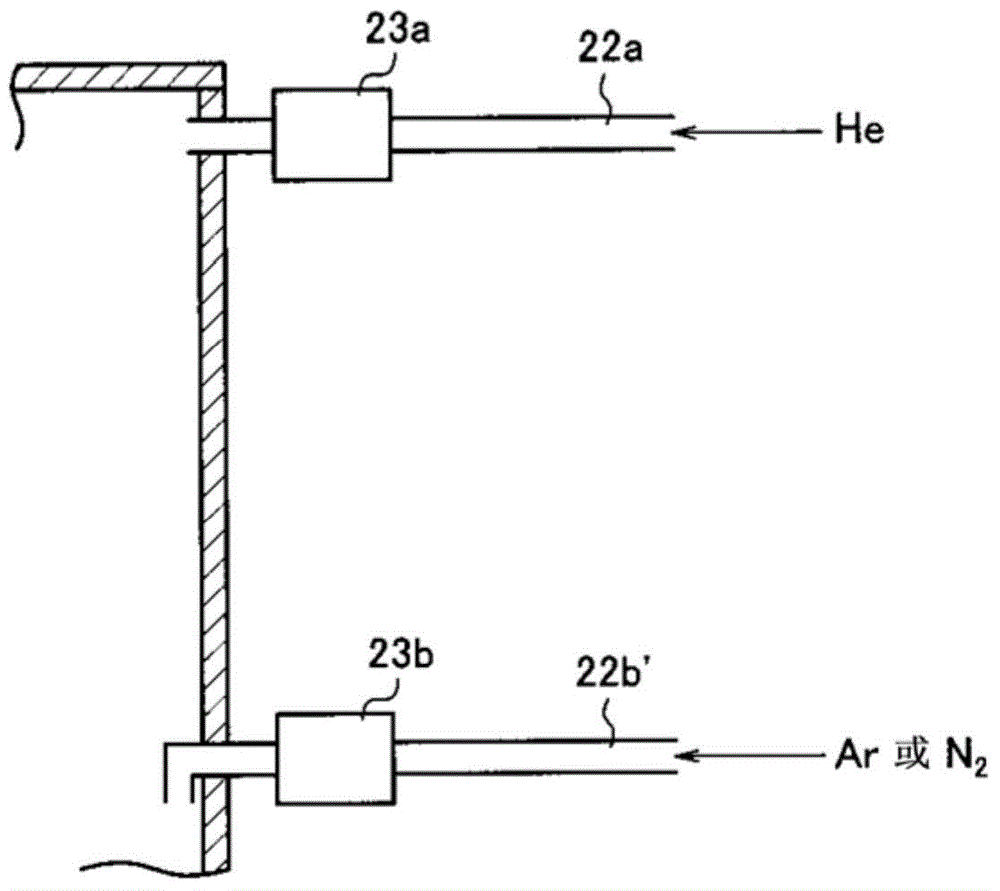

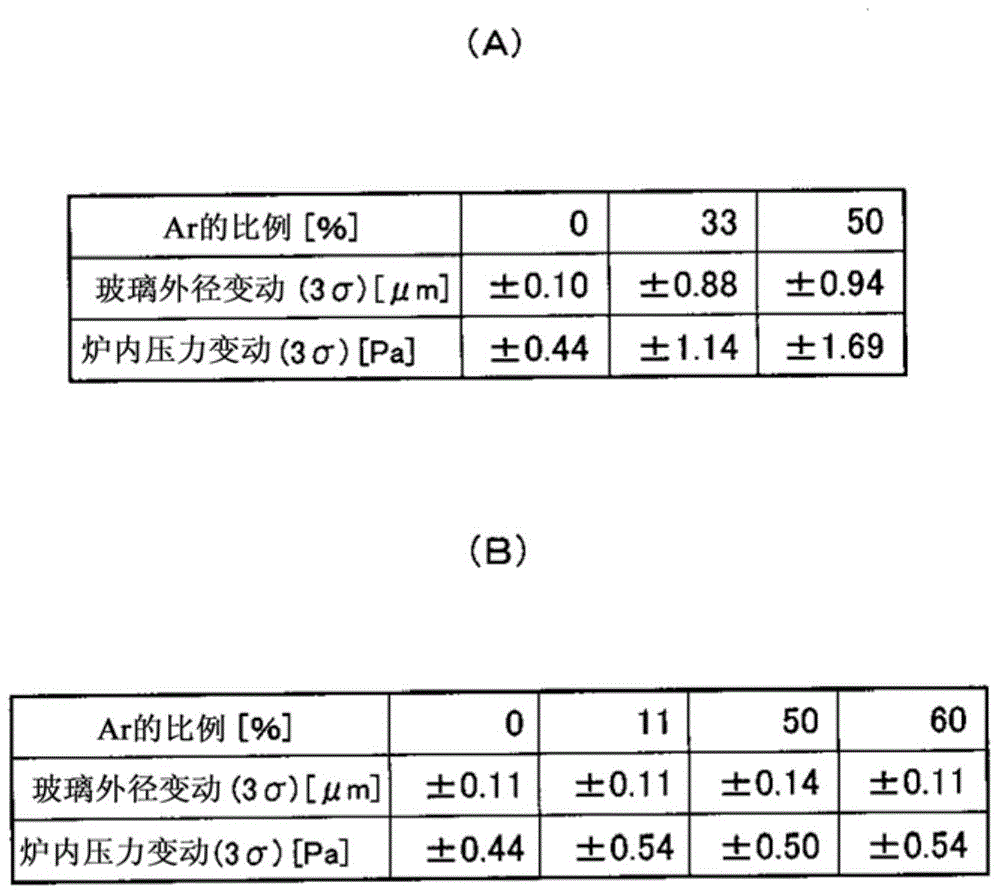

[0016] In the case of using helium gas as an inert gas supplied to the drawing furnace, since this helium gas is expensive and rare, it has been proposed to mix and use a relatively cheap gas such as argon gas. In this case, simply mixing argon and helium will cause pressure fluctuations in the furnace, and the glass diameter of the optical fiber may fluctuate due to the pressure fluctuations.

[0017] The pressure fluctuation in the wire drawing furnace can be considered to occur inside the upper chamber. That is, the upper chamber is disposed above the core tube surrounded by the heater, so the gas heated by the heater rises toward the upper chamber and descends again after being cooled inside the upper chamber. At this time, if argon or nitrogen is used, the density difference (temperature difference) between the gas density in the upper chamber and the gas density in the core tube increases, and it is conceivable that the furnace pressure fluctuation is likely to occur due...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com