Mass production method for ultra-fine bonding gold wire

A production method and alloy wire technology, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as difficulty in production, alarm, and low yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

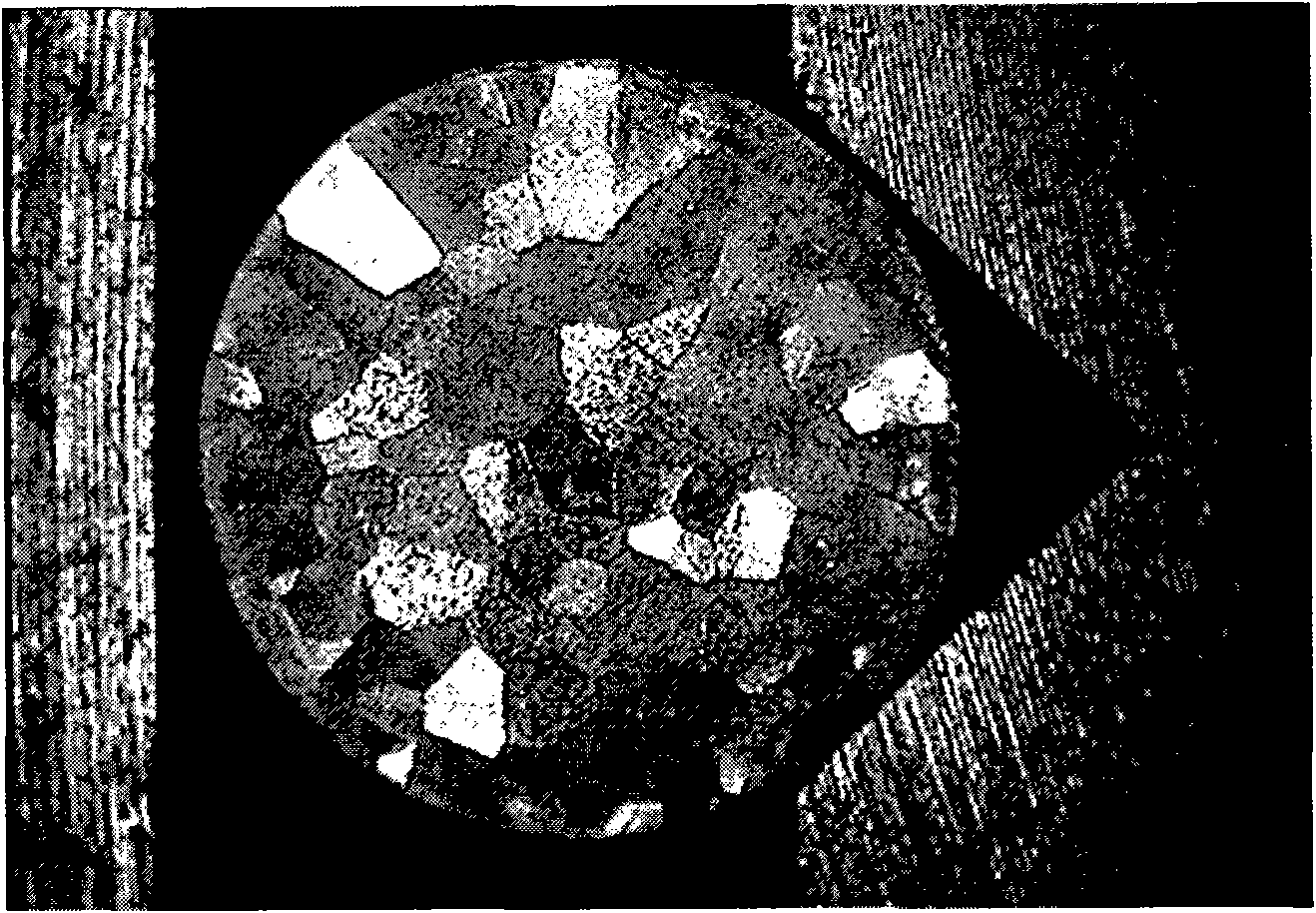

Image

Examples

Embodiment Construction

[0022] In order to allow the above-mentioned and other objects, features and advantages of the present invention to be more clearly understood, the preferred embodiments of the present invention are now specifically cited, together with the accompanying drawings, as follows in detail:

[0023] The large-scale production method of ultra-fine bonding gold wire of the present invention is an improvement of the existing production process, so the common points with the prior art will not be described in detail, and the improved process of the present invention will be described in detail here.

[0024] Common bonded gold wire production methods include casting process (alloy casting), wire drawing process (large drawing, medium drawing, fine drawing, ultra-fine drawing), annealing process (finished product annealing, performance testing), winding process (size Rewind).

[0025] Among them, the melting and casting alloying process is the basis, which determines the processability a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com