A kind of preparation method of meat floss

A production method and technology of meat floss, applied in the directions of food preparation, application, food science, etc., can solve the problems affecting the quality of meat floss products, the damage of meat fiber is large, and the taste of meat floss is poor, so as to achieve the preservation of nutritious flavor, enhancement of brightness, and rich nutrition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

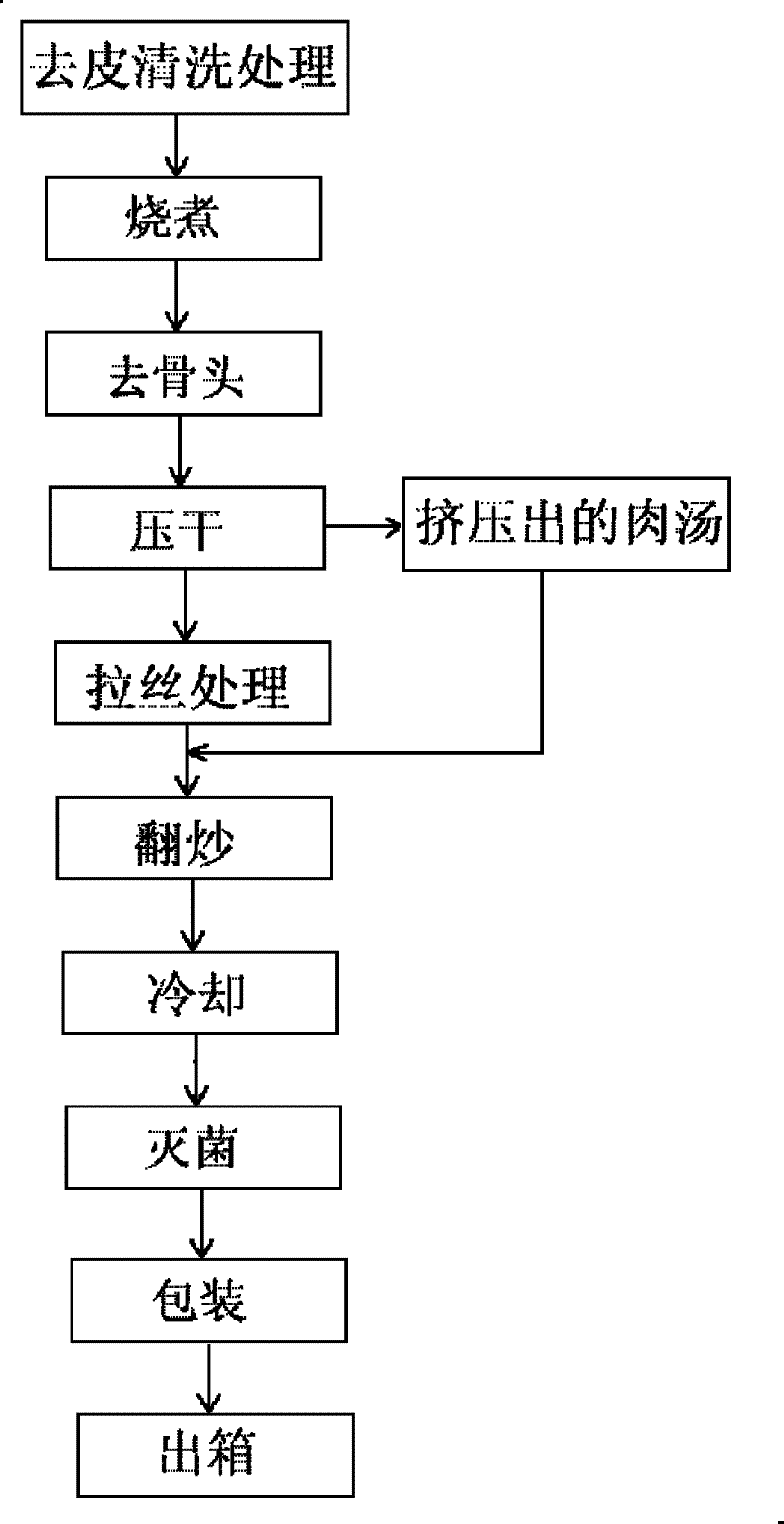

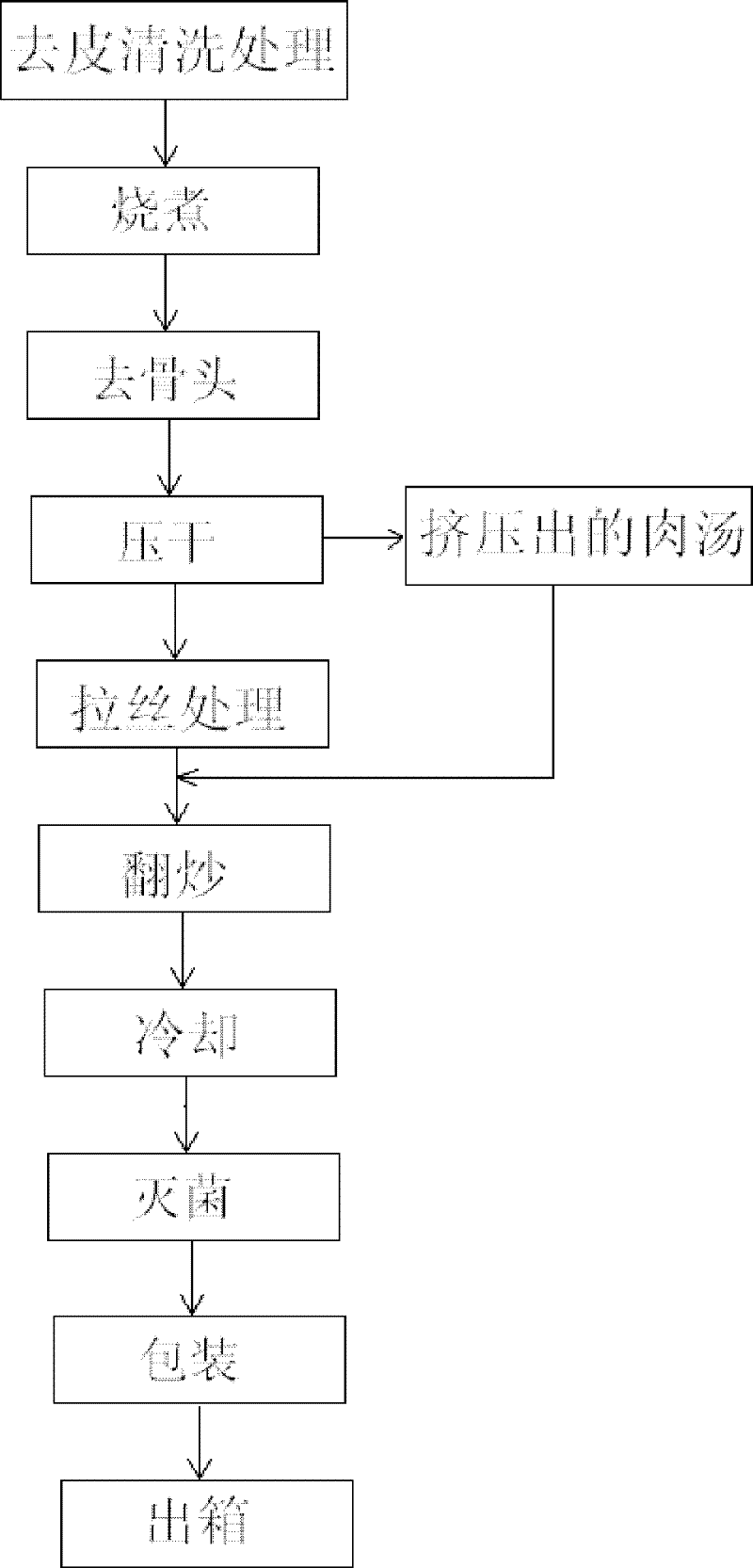

[0021] As shown in the accompanying drawing, the specific production method of meat floss is as follows:

[0022] (1), get fresh pork leg meat and carry out peeling cleaning process;

[0023] (2) Add the prepared soup to the washed pork leg and stir for 2-3 hours;

[0024] Among them, the ingredients of the soup are: every 100KG pork leg meat ingredients are: rock sugar 150g, peanut oil 200g, ginger 100g, fennel 45g, green onion 400g, refined salt 60g, monosodium glutamate 20g, soy sauce 200g, rice wine 40g.

[0025] (3), pour the stirred pork leg meat and soup stock into the interlayer pot, cook with a slow fire for 8 hours, and remove the bones;

[0026] (4), the deboned meat fiber is pressed dry to a water content of 20% to 23%, and the extruded broth is set aside;

[0027] (5), the dried meat fibers are drawn with a wire drawing machine, then added to the broth to be used in step (4), after stirring evenly, stir-fried using a drum-type stir-frying machine;

[0028] (6) ...

Embodiment 2

[0031] As shown in the accompanying drawing, the specific production method of meat floss is as follows:

[0032] (1), get fresh pork leg meat and carry out peeling cleaning process;

[0033] (2) Add the prepared soup to the washed pork leg and stir for 2-3 hours;

[0034] Among them, the ingredients of the soup are: every 100KG pork leg meat ingredients are: rock sugar 100g, peanut oil 250g, ginger 150g, fennel 40g, green onion 450g, refined salt 50g, monosodium glutamate 40g, soy sauce 100g, rice wine 20g.

[0035] (3), pour the stirred pork leg meat and soup stock into the interlayer pot, cook with a slow fire for 10 hours, and remove the bones;

[0036] (4), the deboned meat fiber is pressed dry to a water content of 23% to 25%, and the extruded broth is set aside;

[0037] (5), the dried meat fibers are drawn with a wire drawing machine, then added to the broth to be used in step (4), after stirring evenly, stir-fried using a drum-type stir-frying machine;

[0038] (6)...

Embodiment 3

[0041] Other steps are equal to embodiment 1,

[0042] Cook in step (2) for 9 hours;

[0043] Soup ingredients use the following proportions:

[0044] The ingredients for every 100KG pork leg meat are: 200g rock sugar, 400g peanut oil, 200g ginger, 60g fennel, 600g green onion, 80g refined salt, 30g monosodium glutamate, 450g soy sauce, 60g rice wine.

[0045] The meat floss produced by the above production method is suitable for customers with a sweet taste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com