Ring set welding tool

A welding tool and set technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor welding quality, inability to clamp the ring plate, welding deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

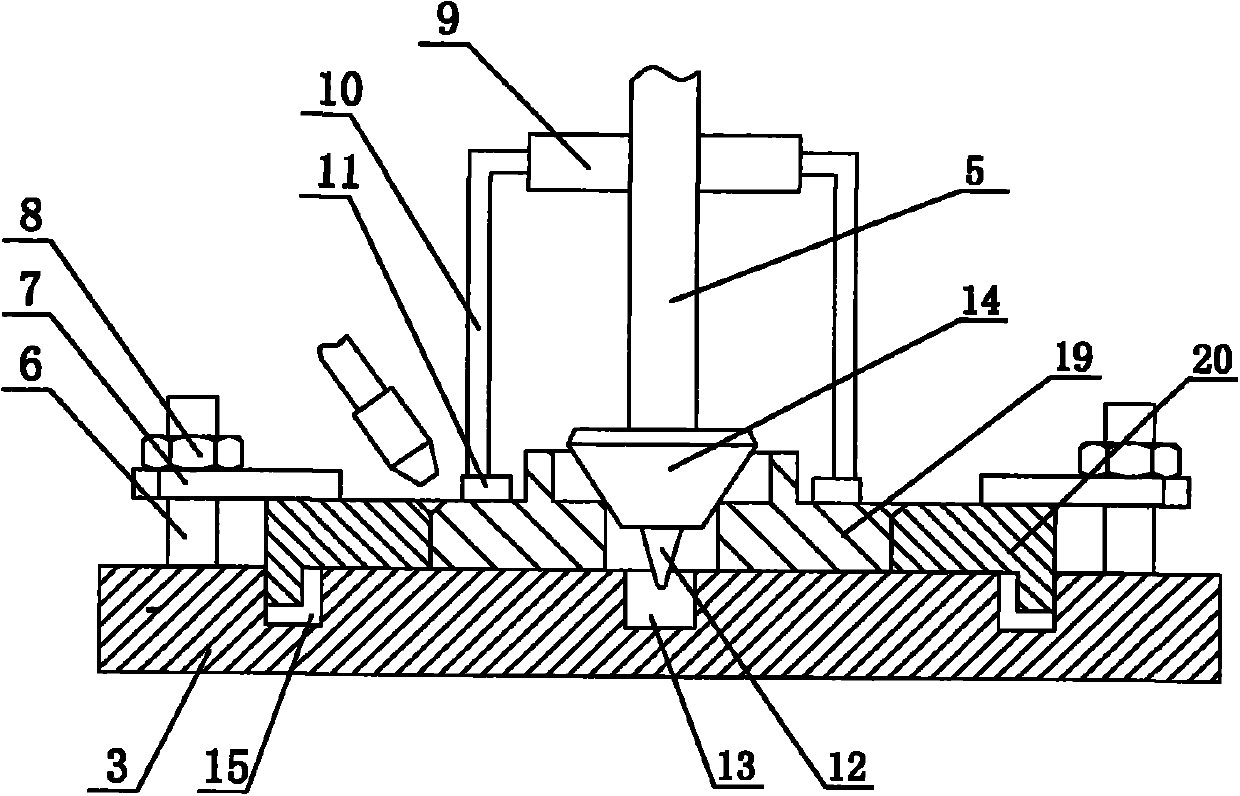

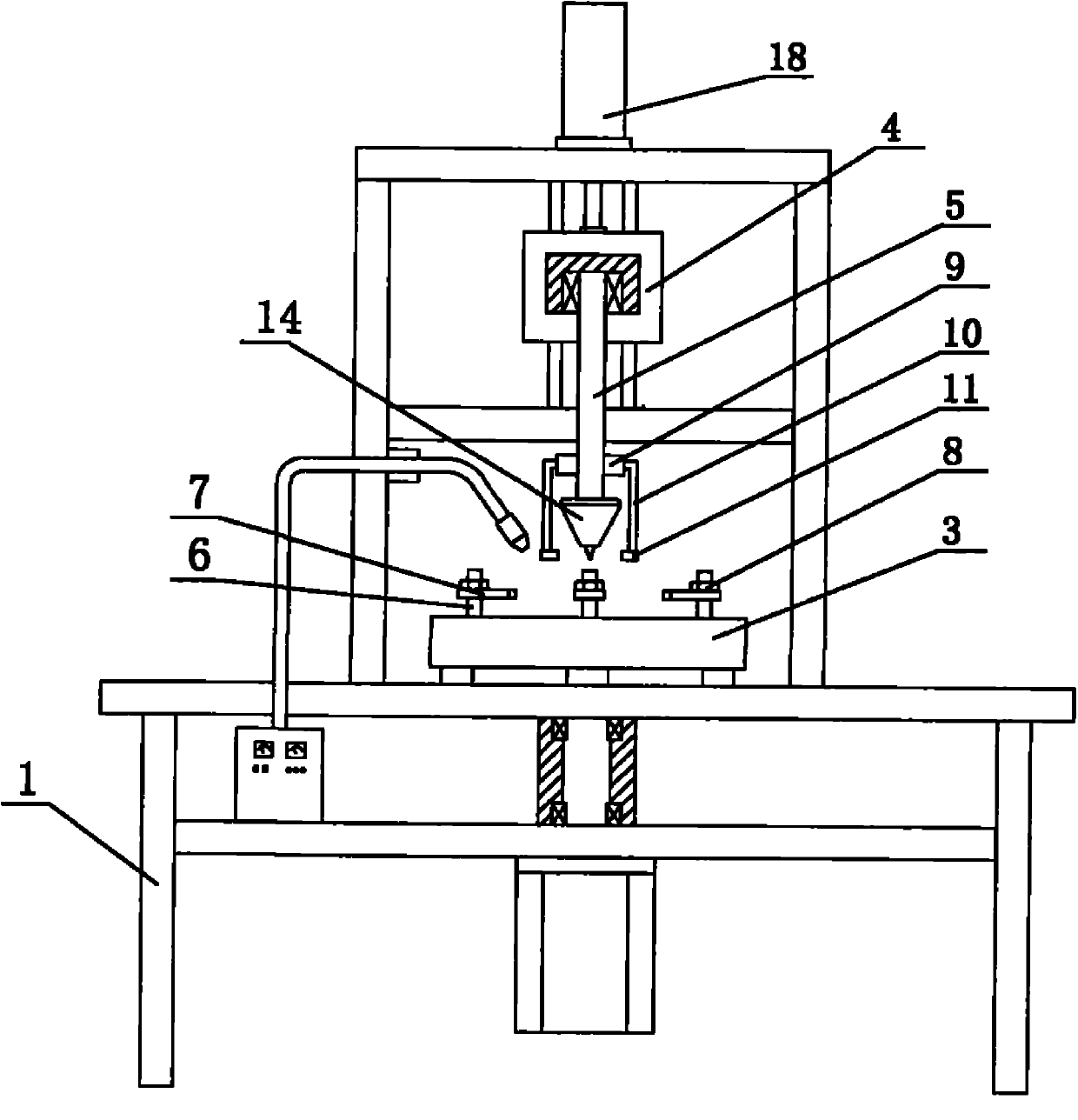

[0014] like figure 1 and figure 2 The circular ring suit welding tool shown includes a workbench 3 connected to the frame 1. The workbench 3 is provided with a ring groove 15 for inserting the ring protrusion of the outer ring, and the workbench 3 is equipped with an outer ring clamp. , the frame 1 is also equipped with a support 4 that is driven by a vertical power mechanism to slide up and down and is located above the workbench 3. The vertical power mechanism is a drive cylinder 18, and the support 4 is connected to the frame through the structure of the guide rail slide seat. The top of 4 is connected with the piston rod power of drive cylinder 18, and the support arm 5 that stretches down is connected with rotation on the support 4, and the inner ring fixture is housed on the support arm 5, and the downward extension end of support arm 5 and workbench 3 are installed There is an inner ring positioning mechanism. The outer ring fixture comprises a plurality of positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com