Mould locking device structure of hollow plastic product forming machine

A technology for plastic products and mold clamping devices, which is applied in the field of mold clamping device structures, can solve problems such as increased cost of use, troublesome manufacturing and assembly, complex overall structure, etc., and achieves the effects of prolonging service life, concise overall structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

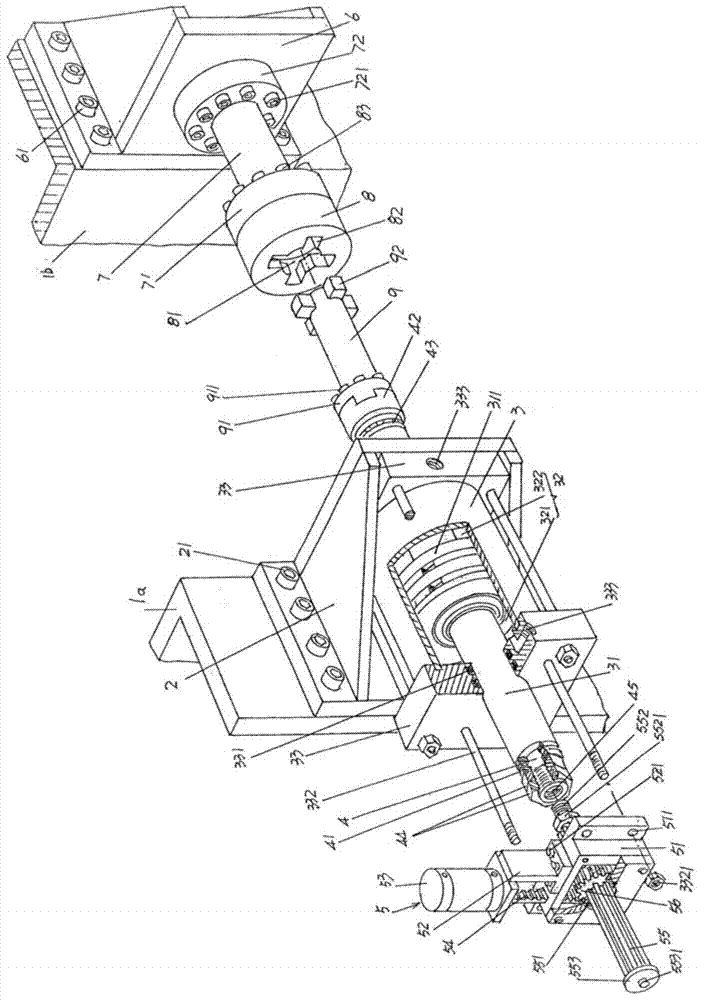

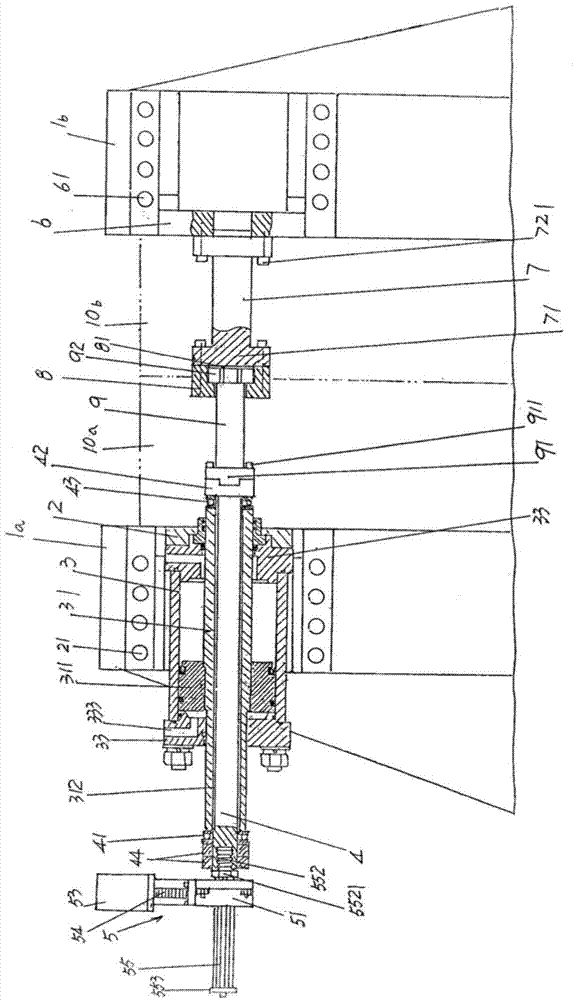

[0025] Please see figure 1 , the left mold base 1a and right mold base 1b belonging to the structural system of the hollow plastic product molding machine are given. According to professional knowledge, the left half mold 10a is installed on the left mold base 1a ( figure 2 shown), and on the right mold base 1b and at the position corresponding to the left half mold 10a, the right half mold 10b is installed ( figure 2 Show). Furthermore, according to professional common sense, between the left and right formworks 1a and 1b, it is usually necessary to set a plurality of the same structure, such as two, four or six mold clamping device structures belonging to the structural system of the present invention. The specific reason can be found in Paragraph 0025 of the description of China Invention Patent Authorization Announcement No. CN101890805B and Publication No. CN102848558A.

[0026] The following is for one of the multiple clamping device structures arranged between the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com