Cable pulling device

A puller and cable technology, which is applied to the installation of cables, cable installation devices, electrical components, etc., can solve the problems of time-consuming, labor-intensive, low work efficiency, and inconvenient holding of the cable body, and achieve high operating efficiency and easy use. Convenient and fast, avoiding the effect of twisting and accumulating the cable body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

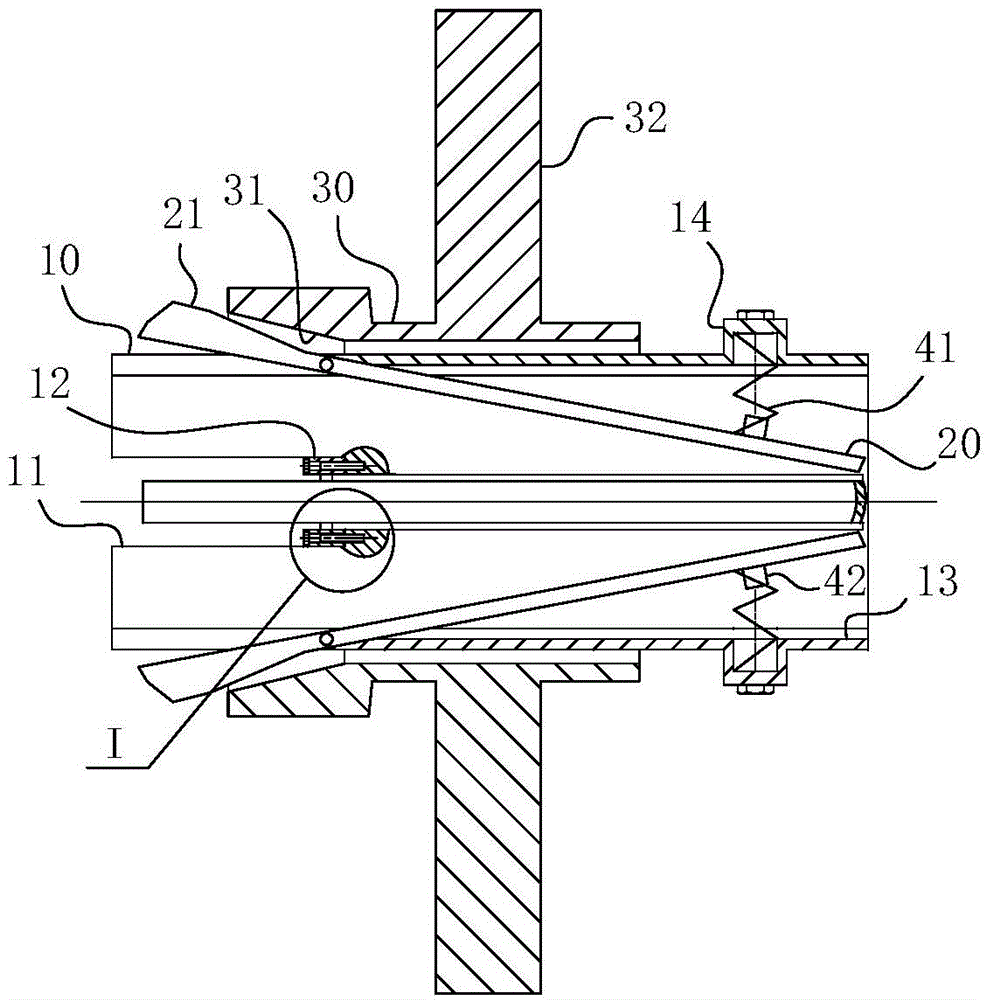

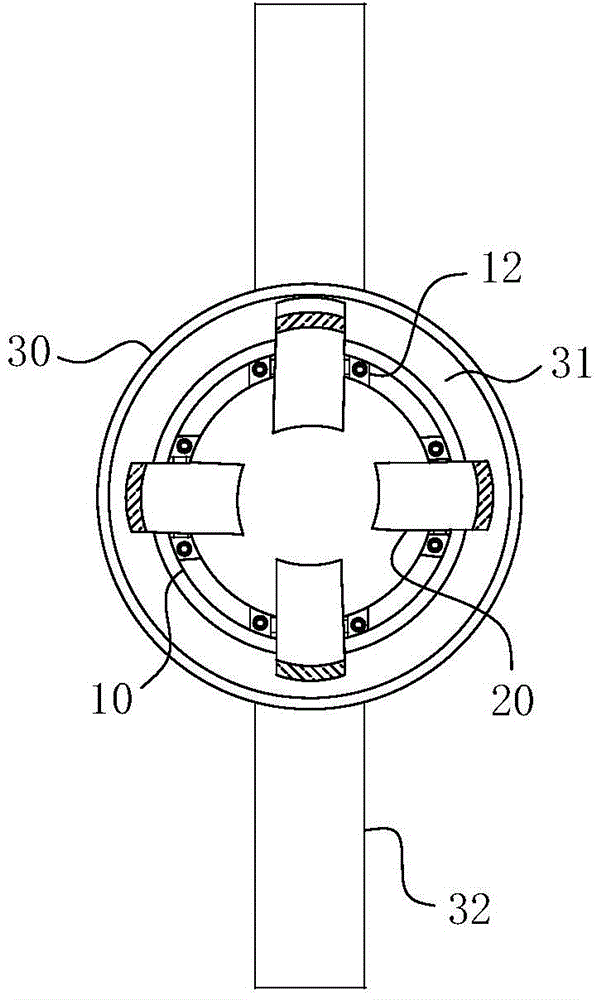

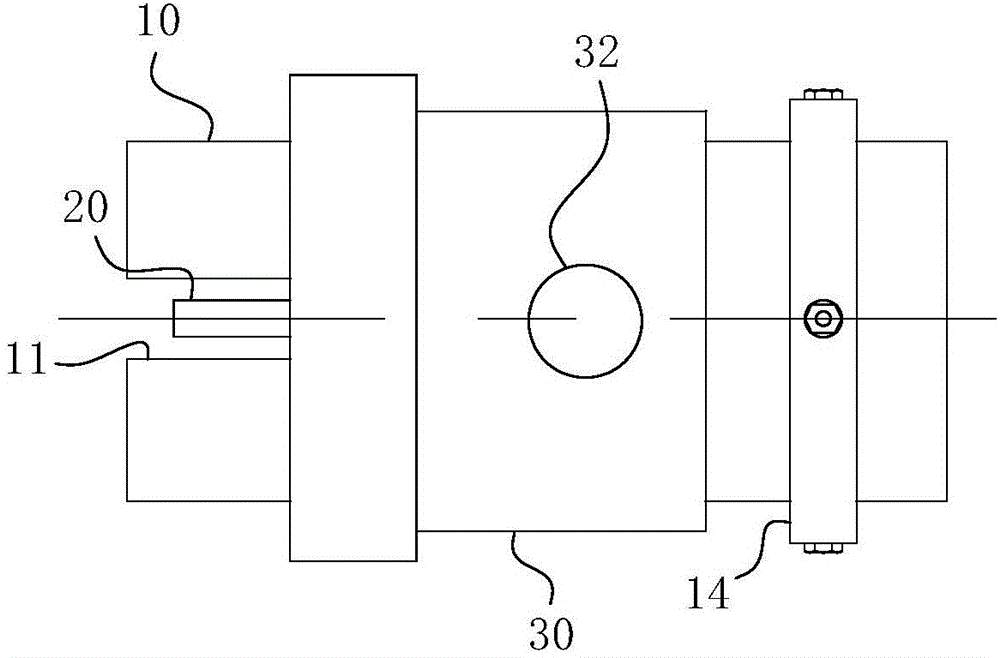

[0038] combine here Figure 1-7 The specific implementation structure and work flow of the present invention are further described as follows:

[0039] For ease of understanding, the arc side of the clamp rod 20 facing the axis of the collar portion 10 is used as the inner wall, and the arc side facing away from the axis of the collar portion 10 is also the outer wall; at the same time, the present invention The action direction of the cable body inserted into the cable a is its forward action direction, and the pulling direction of the cable body relative to the cable a is its reverse backward action direction.

[0040] Concrete implementation structure of the present invention, refer to Figure 1-4 As shown, it includes a collar part 10 for being directly sleeved on the cable body of the cable a. The collar part 10 is provided with a tapered clamping tooth formed by a clamp rod 20 around the axis of the collar part 10 (that is, a clip The shape of the conical clamping teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com