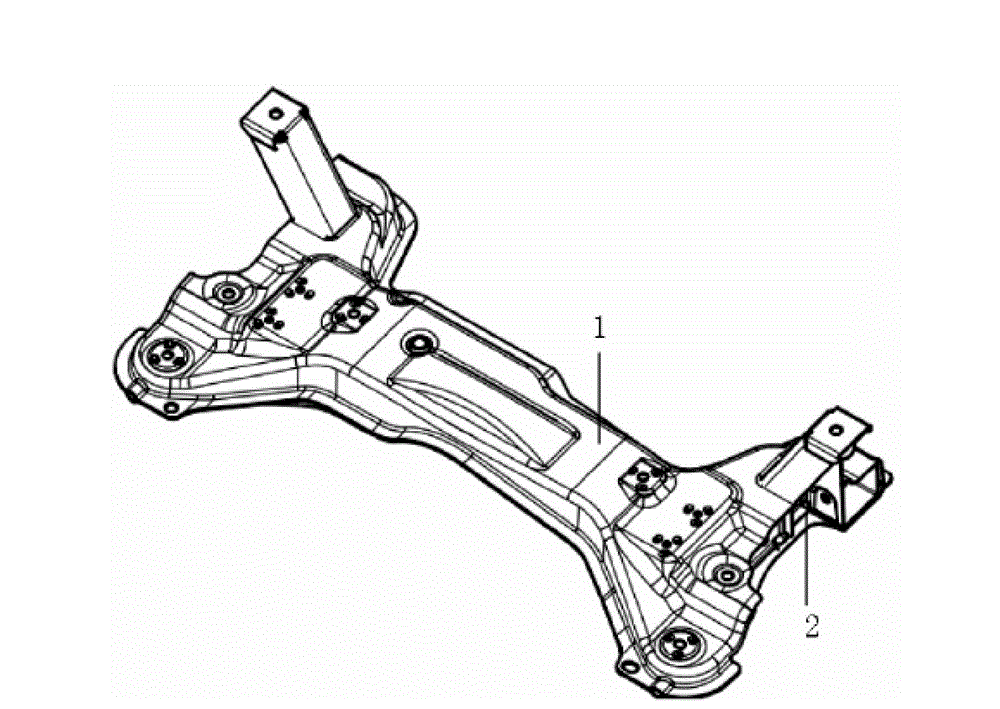

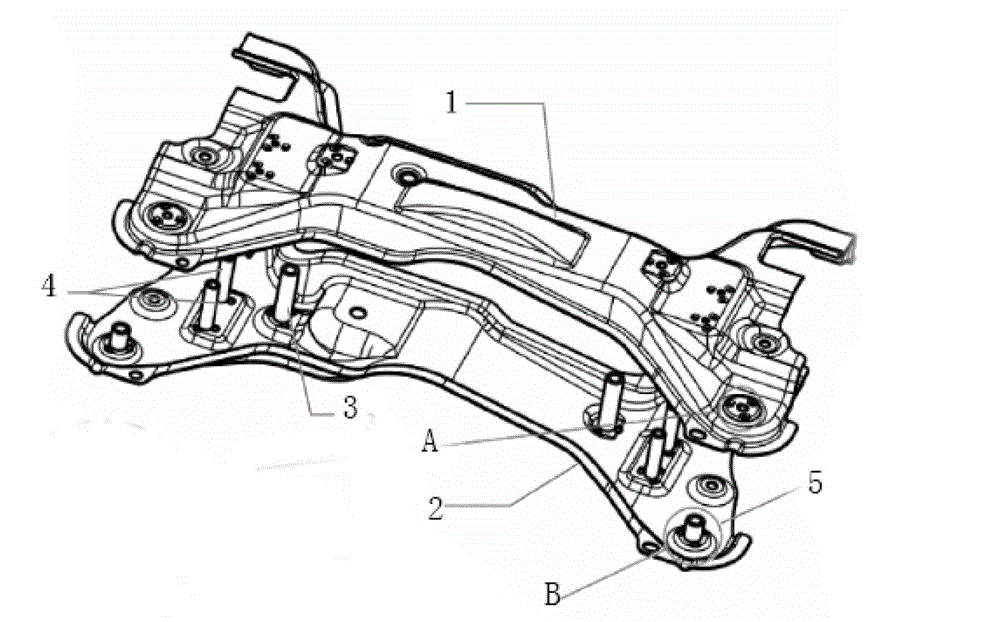

Auxiliary frame mechanism of automobile

A sub-frame and automobile technology, applied in the substructure, vehicle parts, transportation and packaging, etc., can solve the problems of poor flatness at key installation points, increased labor costs, welding spatter, etc., to improve dimensional accuracy and fatigue life , reduce the risk of torque loosening, and avoid the effect of welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

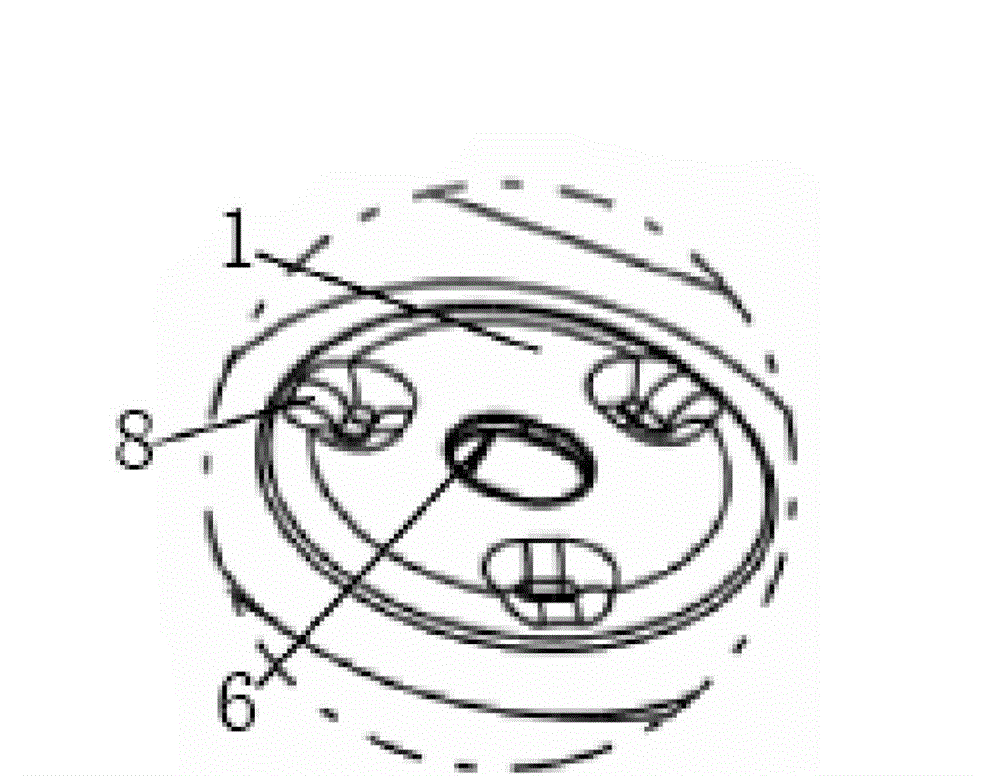

[0045] In the present invention, because the steering gear installation sleeve, the stabilizer bar installation sleeve, and the subframe have the same structure as the limiting bosses in the vehicle body installation sleeve, only the auxiliary frame and the vehicle body installation sleeve among them have the same structure. The structure of the limiting boss is described in detail, and the others are the same as the structure.

[0046] The first mounting hole for the subframe and the body mounting sleeve is arranged on the upper plate of the subframe, and the first mounting hole for the subframe and the body is provided on the lower plate of the subframe corresponding to the first mounting hole for the subframe and the body mounting sleeve. Install the second mounting hole of the sleeve; the surroundings of each mounting hole are stamped and formed three limit bosses at one time, and the number of limit bosses can be changed according to needs, but at least three limit bosses,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com