Machining process of hydraulic support lifting jack cylinder

A technology of hydraulic support and processing technology, which is applied in the direction of lifting devices, etc., which can solve the problems of inability to eliminate welding internal stress, long production cycle, and short product life, and achieve the effects of eliminating welding internal stress, prolonging service life, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

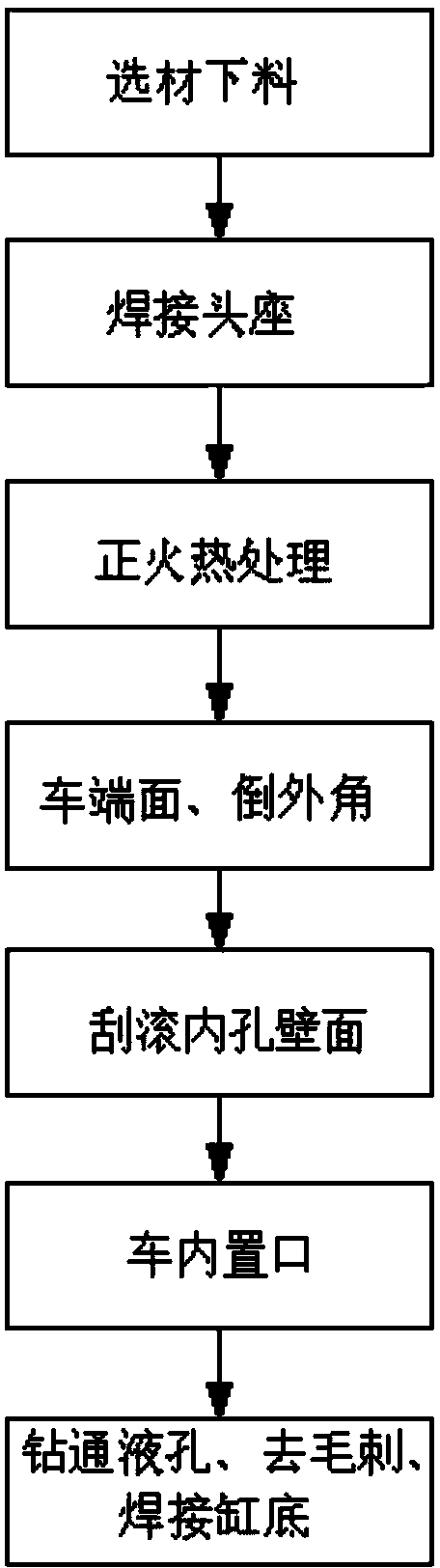

[0029] Such as figure 1 As shown, the main steps of the processing technology of the present invention are material selection and blanking, welding head seat, normalizing heat treatment, turning end face, chamfering outer corner, scraping and rolling inner hole wall surface, turning inside hole, drilling through liquid hole, deburring, welding cylinder end.

[0030] The steps briefly described above can be specifically the following steps:

[0031] Step 1) Select the pipe material of 27SiMn as the processing raw material of the cylinder barrel. After the pipe material is qualified, the size is determined and the material is cut to obtain the cylinder barrel. In this step, the following steps are included: first, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com