Circle supporting device for the inner side of a thin-wall metal pipeline

A metal pipe and thin-walled technology, which is applied in the field of rounding devices inside thin-walled metal pipes, can solve the problems of pipe becoming elliptical, its own strength unable to resist shrinkage deformation, collapse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with embodiment the present invention is described in further detail:

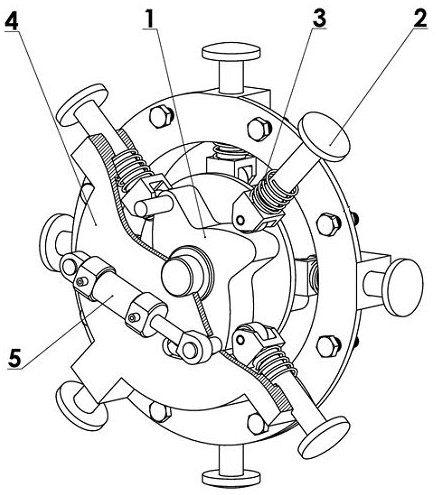

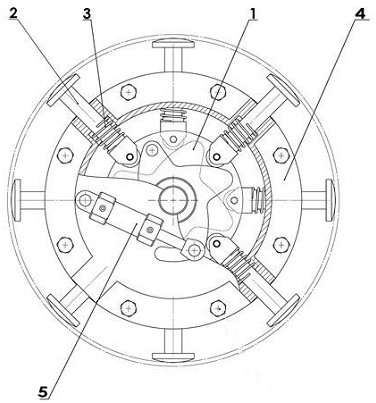

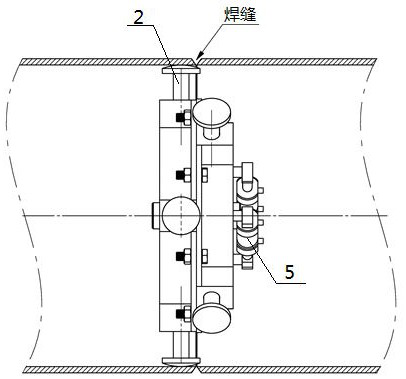

[0032] Such as Figure 1 to Figure 12 As shown, the present invention is a thin-walled metal pipe inner rounding device for rounding the inner side of the thin-walled pipe with an inner diameter of 100 to 400 mm and welding the outer side to prevent deformation. It includes a rotatable camshaft Body 1 and 8 ejector rod assemblies 2 that expand and contract along the camshaft body 1, and the outside of the camshaft body 1 and the ejector rod assembly 2 is covered with a casing 4, the camshaft body 1 includes a rotating shaft 11 arranged in the middle, and the The two sides of the rotating shaft 11 are respectively provided with a "windmill"-shaped cam 12 with 4 uniformly distributed and equal fan blades in the circumferential direction, and the two cams 12 on both sides are misplaced by 45°, so that each fan of the cams 12 on both sides The leaves are spaced at 45° to drive 8 pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com