Method for controlling deformation of principal welding seam of ship crane

A technology of welding deformation and control method, which is applied in welding equipment, manufacturing tools, metal processing equipment, etc., to achieve the effect of reducing production costs, reducing production costs, and promoting application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Next, embodiments of the present invention will be specifically described.

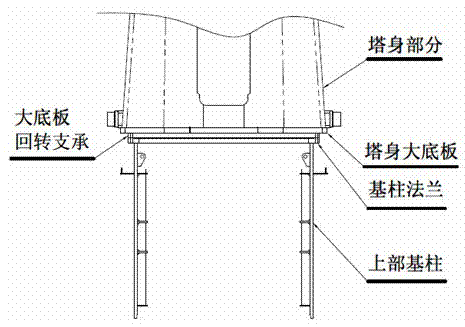

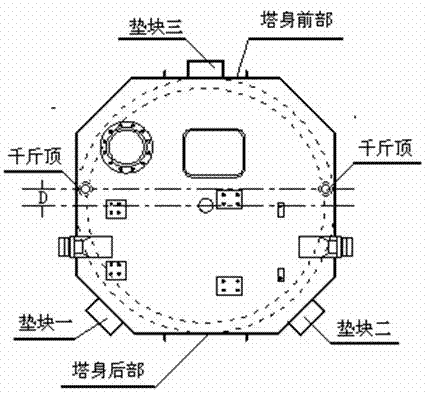

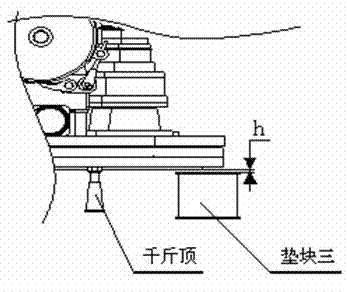

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention adopts the process of controlling welding deformation, and the process of controlling welding deformation includes: 1) controlling the welding current, transforming the welding machine used for the welding of the gram lifting buckle tower, installing a current limiting device, and controlling the welding machine through the current limiting device 2) Reduce the welding deformation caused by welding heat, adopt symmetrical welding process, formulate the welding sequence of symmetrical welding, and disperse the welding process Grasp the heat input caused by the large bottom plate of the lifting tower; 3) Predict the deformation point, and use the anti-deformation process for the predicted deformation point to reduce the deformation after welding. The anti-deformation process adopted is to set tooling a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com