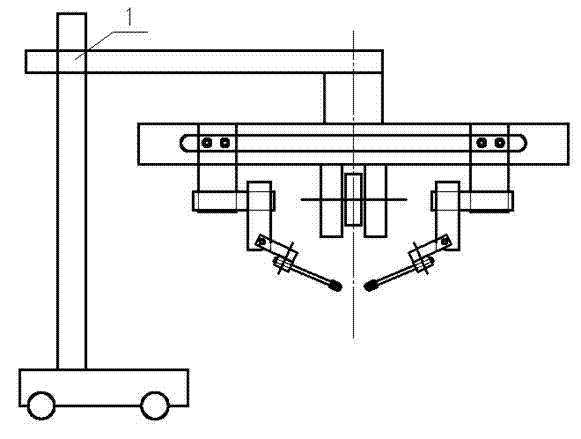

Automatic welding device for annular symmetrical fillet welds

An automatic welding, ring-symmetrical technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of unsightly appearance of manual welding fillet welds, easy deformation of supporting ring plates, and unsatisfactory welding quality. The appearance of the welding seam is of good quality, avoiding instability, and the welding effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is further described in conjunction with the following examples.

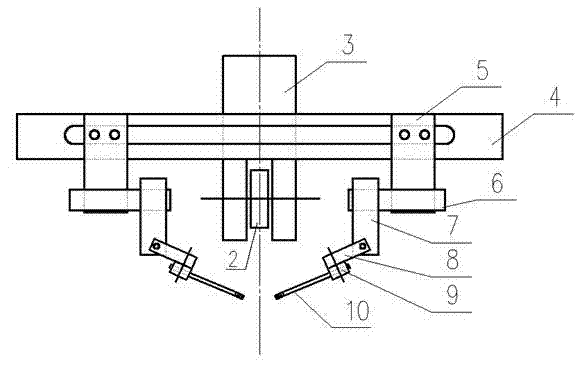

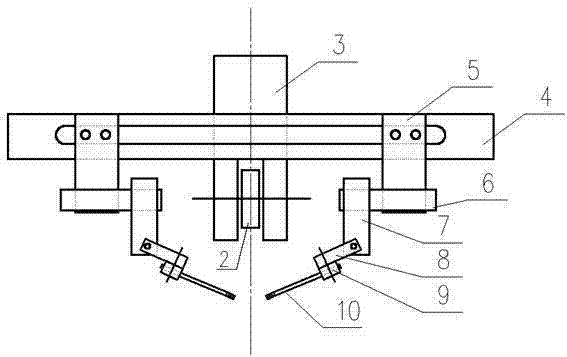

[0042] A specific embodiment of an automatic welding device for annular symmetrical fillet welds of the present invention includes a support device, a fixed connecting arm 3 and a horizontal slide rail 4, and the fixed connecting arm 3 and the horizontal slide rail 4 are vertically intersected and fixed connect. Preferably, the fixed connecting arm 3 is fixedly connected to the horizontal slide rail 4 through bolts, so that a large position adjustment can be realized.

[0043] Specifically, one side of the fixed connection arm 3 is fixed to the support device, and the other side of the fixed connection arm 3 is provided with a rotatable guide wheel 2; preferably, the rotatable guide wheel 2 passes The rotating shaft is connected with the other side of the fixed connecting arm 3 . The guide wheel 2 plays a guiding role when the workpiece rotates, and ensures the dynamic adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com