Flue system combined jig frame and flue system assembling method

A flue system and assembly method technology, applied in the direction of manufacturing converters, etc., can solve the problems of inability to reuse the heating surface tube, damage to the heating surface tube, and high consumption of materials, so as to improve assembly construction efficiency, high reuse rate, The effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

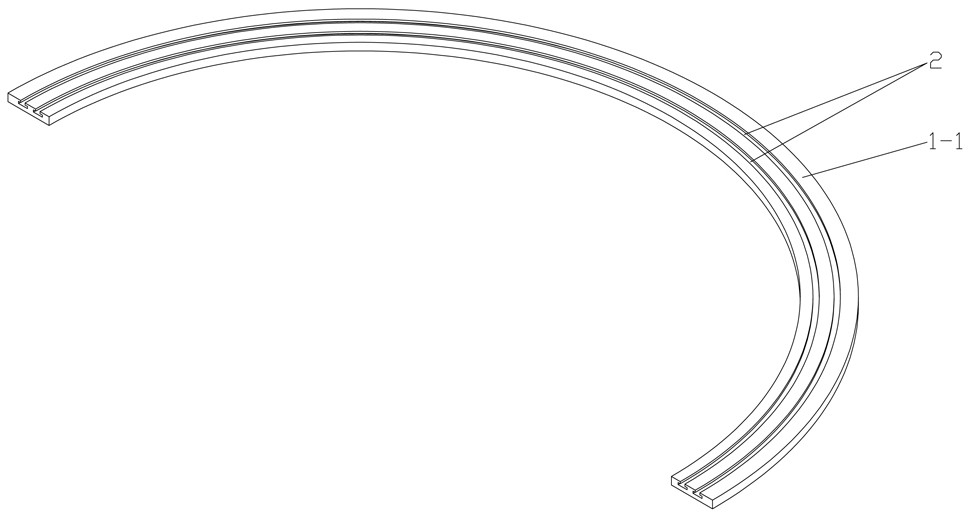

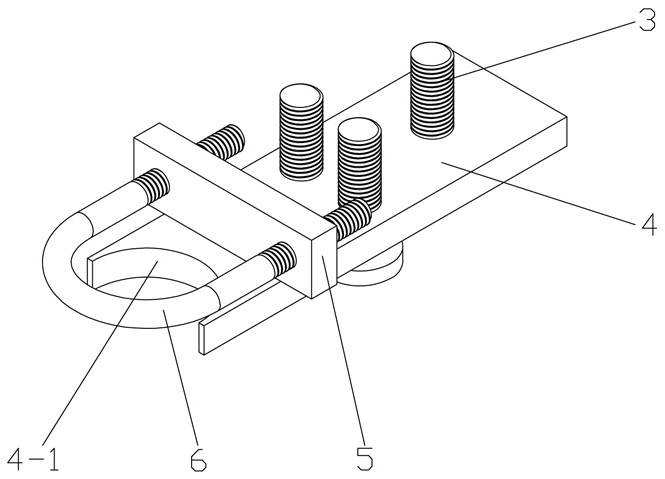

[0033] Such as figure 1 , figure 2 as well as image 3 As shown, the combined tire frame of the flue system of the present invention includes an annular reinforcing ring 1, the reinforcing ring 1 is formed by splicing several arc-shaped plates 1-1 sequentially end to end, the plate surface of the reinforcing ring 1 and its central axis vertical. On the plate surface of the reinforcing ring 1 side, some movable clamping plates 4 are slidably installed, and the inner end of the movable clamping plate 4 is provided with an arc-shaped notch 4-1, and the arc-shaped notch 4-1 is located at the inner ring of the reinforcing ring 1. On the inner side, a connecting plate 5 is fixed on the movable clamping plate 4, the two arms of the U-shaped clamp 6 pass through the connecting plate 5, and the arc portion of the U-shaped clamp 6 is located on the inner side of the inner ring of the reinforcing ring 1. After passing the heating surface tube 7 between the arc notch 4-1 and the arc p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com