Curvature-free substrate used for power IGBT module encapsulation

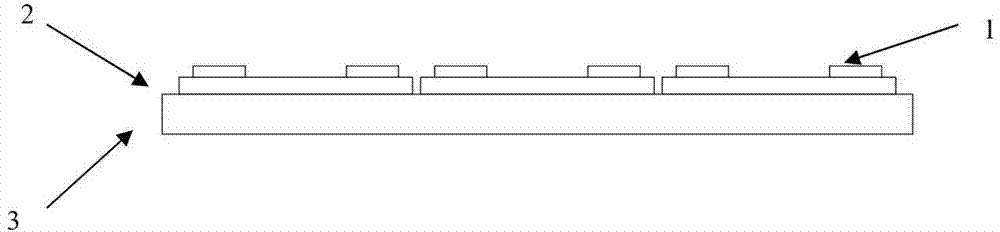

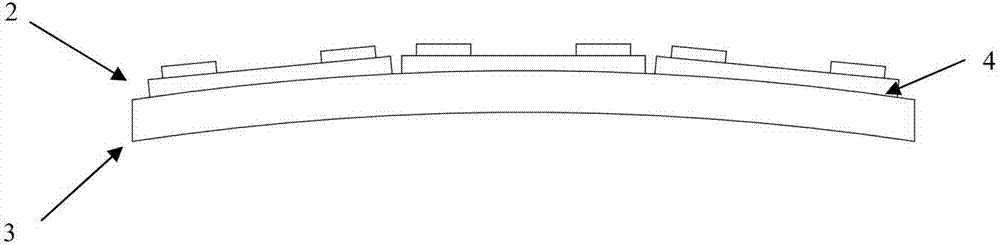

A module packaging and substrate technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems such as the curvature of the IGBT module substrate 3 not meeting the requirements, the adverse impact on the reliability of the IGBT module, and the decline in the packaging yield, so as to reduce the Heat dissipation effect, easy manufacture, and the effect of offsetting welding stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

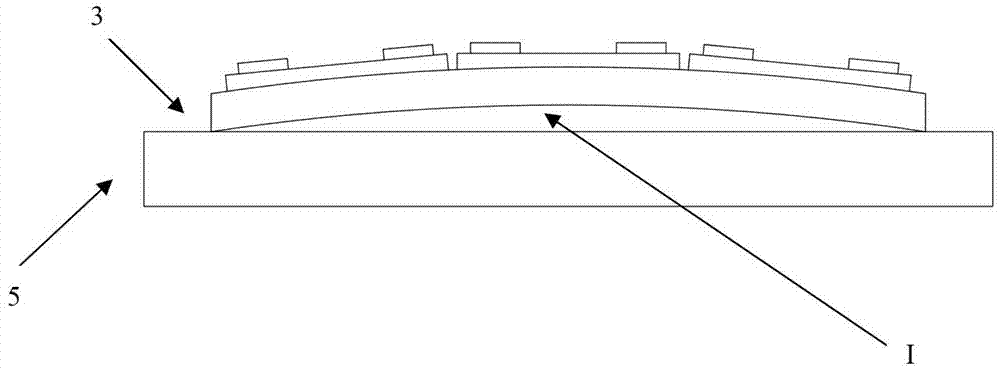

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] Such as Figure 7 and Figure 8 As shown, a non-curvature substrate used for power IGBT module packaging of the present invention includes a substrate body 7, and several welding surfaces 701 of the substrate body 7 (that is, the side welded with the insulating ceramic liner 2) are provided with several The convex mesa 702 and the heat dissipation surface 703 of the substrate body 7 (ie, the side connected to the heat sink 5 ) are flat, and the material used to form the mesa 702 is a material that is easier to deform than the substrate body 7 .

[0031] Such as Figure 9 Shown is a schematic diagram of the welding structure of the substrate and the insulating ceramic liner 2 of the present invention. The substrate body 7 of the present invention is provided with a raised table top 702, and the insulating ceramic liner 2 is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com