Welding device and process method for section-increased cantilever crane body assembly positioning welding

A process method and positioning welding technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems affecting the overall performance of the boom body, the deformation of the boom, and the low welding efficiency, and achieve the convenience of manual welding or welding. Robot welding, avoiding boom deformation and welding deformation, and ensuring the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the drawings.

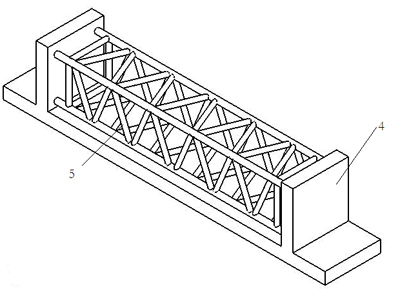

[0034] In the present invention, in order to provide a novel process method for the assembling and positioning welding of the extended boom frame body, firstly, a head and tail type rotatable positioner tooling with a lifting platform is provided. Such as Figure 5 As shown, the head and tail type rotatable positioner tooling with a lifting platform includes a lifting platform 51, a head rotatable positioner 52 and a tail rotatable positioner 53, wherein the head rotatable positioner 52 and the tail The rotatable positioner 53 may have the same structure or a different structure. The head rotatable positioner 52 includes a porous tooling bottom plate 521 and a supporting device 522; the tail rotatable positioner 53 includes a porous tooling bottom plate 531 and a supporting device 532. It can be seen from the figure that the head rotatable positioner 52 and the tail rotatab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com