Welding deformation control fixture for welding of large-scale thin wall storage box structure and welding method

A technology of welding deformation and storage tank, which is applied in the direction of manufacturing tools, welding equipment, welding equipment, etc., can solve the problems of small rigidity, inability to assemble, and heavy weight of welding fixtures, etc., to reduce welding deformation, prevent welding deformation, increase The effect of overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

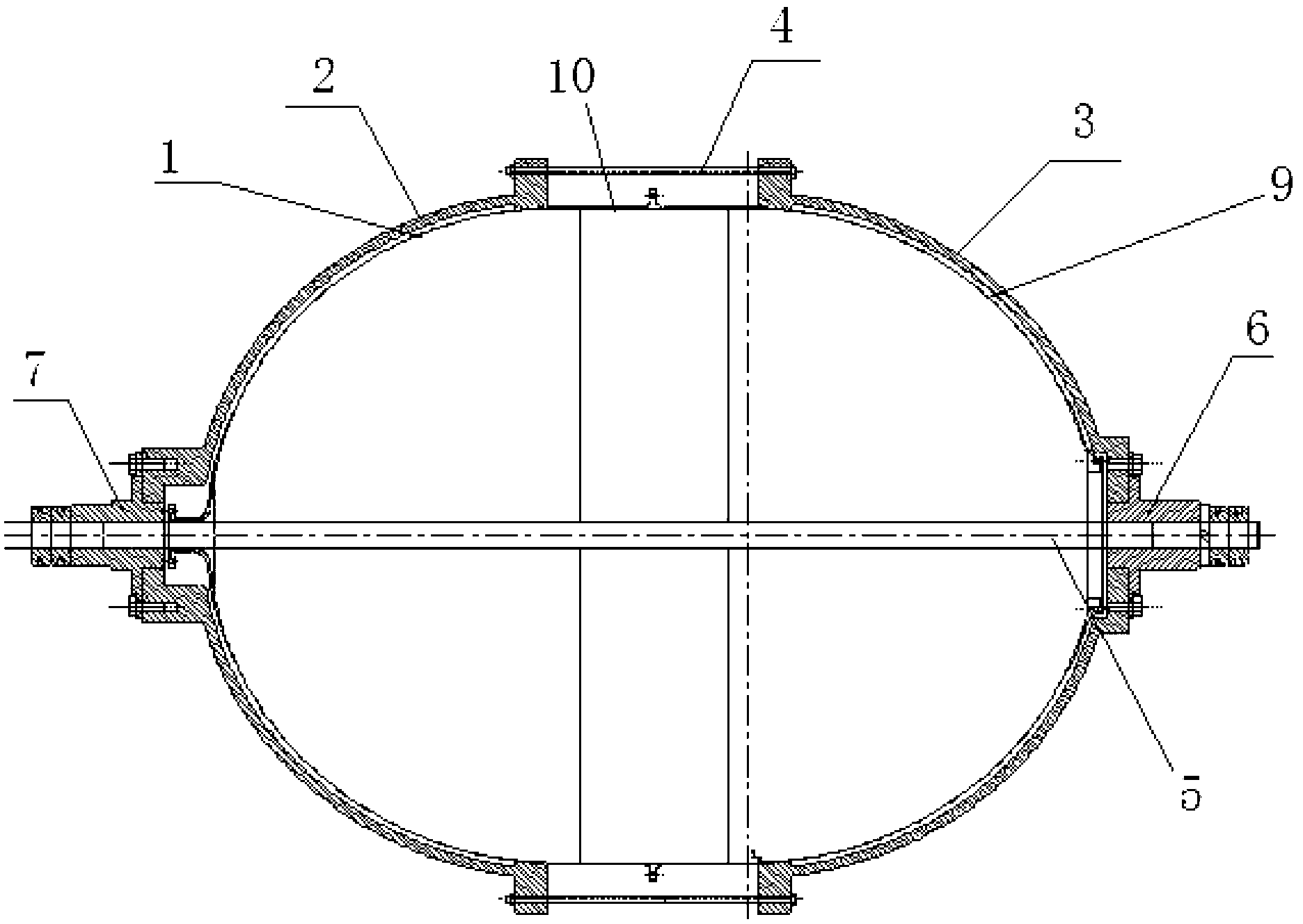

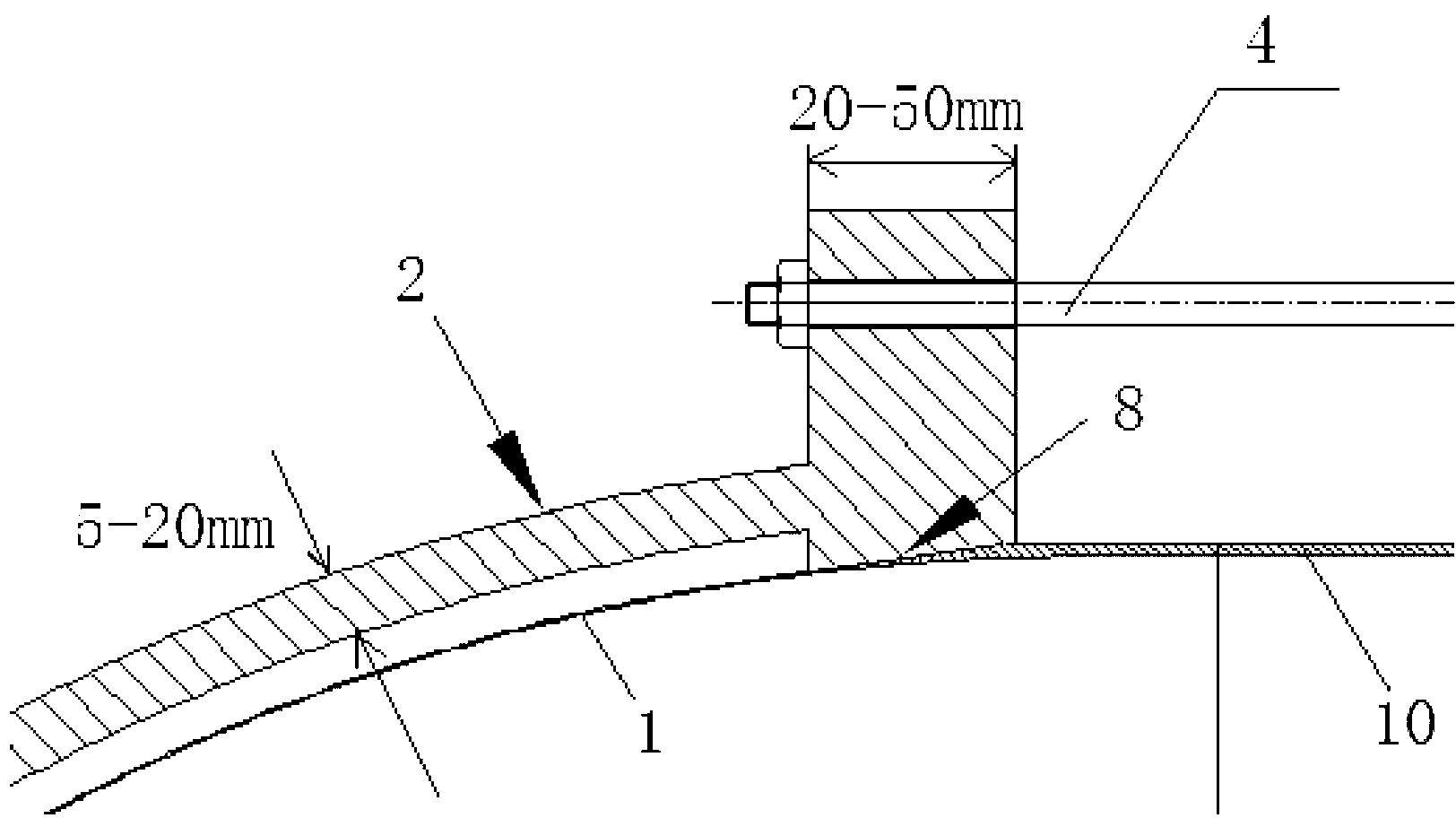

[0027] Such as figure 1 As shown, the large thin-walled tank structure 1 is an aluminum alloy tank with an outer diameter of 950 mm, a wall thickness of the tank flange 10 of 3.0 mm, and a thickness of 1.5 mm at the front bottom 1 of the tank and the rear bottom 9 of the tank. The front bottom 1 of the tank and the rear bottom 9 of the tank are respectively connected to the two ends of the flange 10 of the tank by means of electron beam welding. The ends of the front bottom 1 of the tank and the rear bottom 9 of the tank all have a section of transition area 8, and the thickness of the transition area 8 gradually increases from 1.5 mm to 3.0 mm.

[0028] A fixture for controlling welding deformation according to the present invention is adopted, and the fixture mainly includes a front cover 2, a rear cover 3, a front connector 7, a rear connector 6, and the like. Wherein, wherein the profile of front cover 2 coincides with storage tank front bottom 1 and can cover storage tan...

Embodiment 2

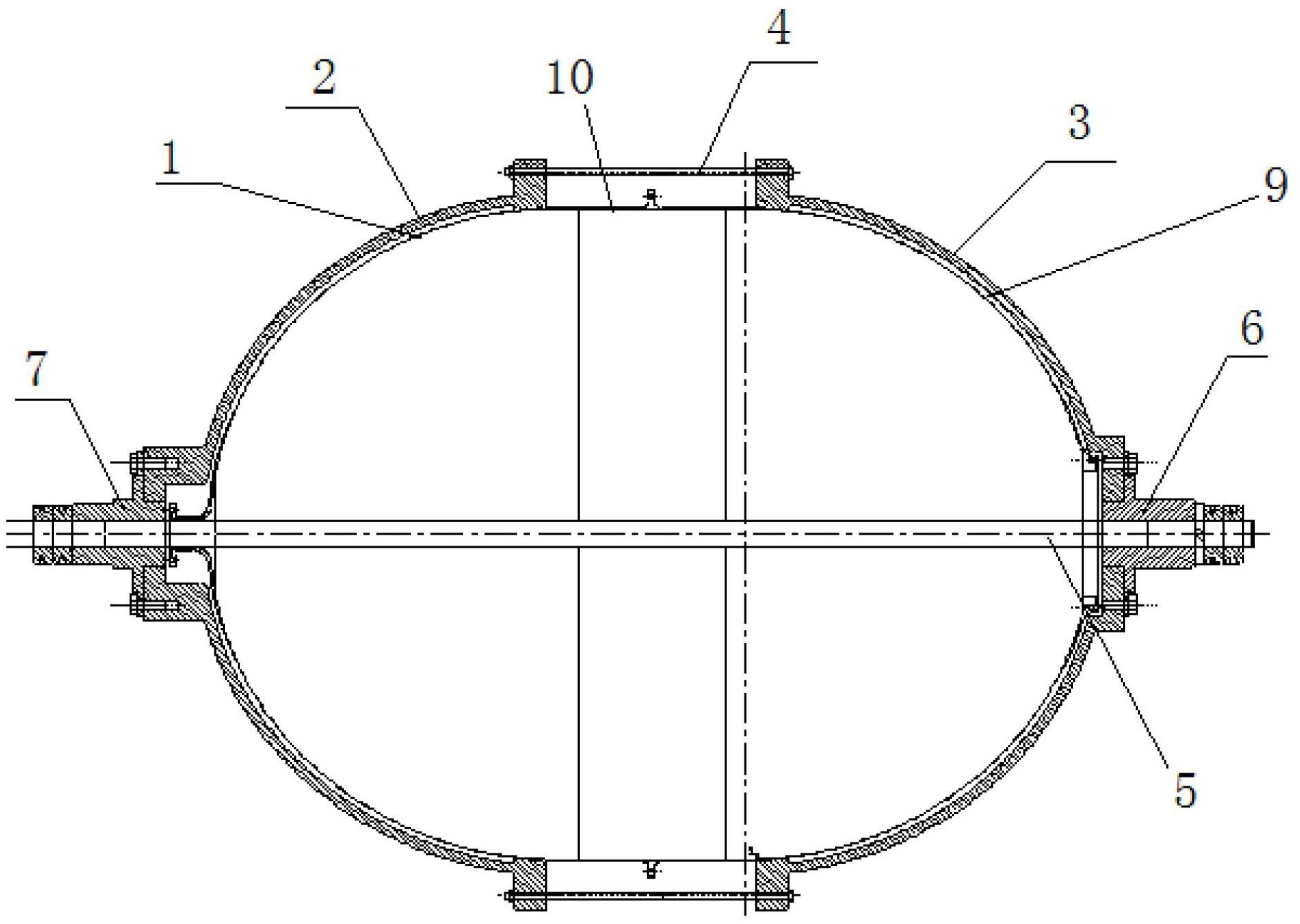

[0034] The large thin-walled tank structure 1 is a titanium alloy tank with an outer diameter of 1050 mm, a wall thickness of the tank flange 10 of 3.0 mm, and a thickness of 1.0 mm at the front bottom 1 of the tank and the rear bottom 9 of the tank. The front bottom 1 of the tank and the rear bottom 9 of the tank are respectively connected to the two ends of the flange 10 of the tank by means of electron beam welding. Both the ends of the front bottom 1 of the tank and the rear bottom 9 of the tank have a section of transition area 8, and the thickness of the transition area 8 gradually increases from 1.0 mm to 3.0 mm.

[0035] The method specifically includes the following steps:

[0036](a) Assemble the front bottom 1 of the storage tank to be connected with the front cover, assemble the rear bottom 9 of the storage tank with the rear cover 3, and place the tank flange 10 on the front bottom 1 of the storage tank and the rear bottom 9 of the storage tank In between, adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com